Lewis Australia is an automation engineering company that designs specialised production equipment for a variety of industries.

We design and build equipment to automate a client’s production processes in areas where there are no applicable standard machines.

Blast hole samplers for drill cone material

Our truck-mounted machine takes samples of drill cone material brought to the surface during the drilling of a blast hole.

In addition, an industrial robot automatically collects this material and deposits it into a hopper for crushing, splitting and bagging.

Recent tests showed sampling errors with the machine were less than one-third of those with manual sampling, leading to more accurate decision-making on how to process the material and greater mined ore consistency.

Lightweight torque gun (Rad gun) extensions

The Lewis Australia Lightening Bolt is an ultra-lightweight torque gun extension and sockets for wheel nut removal and replacement on mining vehicles.

This range of extensions is made from high-strength aluminium and titanium, and each model is a small fraction of the weight of steel extension it replaces. It is light, easy to handle and safe to use. Sites around the world have witnessed increases in production due to ease of use and a reduction in operator injuries.

Haul truck wheel changing robotics for the mining sector

Lewis Australia has developed a robotic machine that automates all of the hazardous manual functions associated with changing haul truck wheels.

The machine works between a haul truck wheel and the wheel handler to accurately locate wheel fasteners within the range of the robot to reach, remove and re-install nuts or bolts to torques up to 4,000Nm, remove or install the set of wheel cleats of the haul trucks, and clean the wheel hub after wheel removal.

It eliminates the majority of manual applications associated with haul truck wheel changes and improves safety, truck up-time and quality of wheel nut torqueing.

Primary metal casting projects

Lewis Australia has a proven history of successful primary metal casting projects.

Our lead casting machine at Nyrstar’s plant in Port Pirie, South Australia, remains the world benchmark for automation, speed and ingot quality. The weight and height consistency and quality are unsurpassed by any other machine.

Our jumbo 30tph zinc casting machine was the first block machine to include automatic low-dross pouring and robotic dross removal. It is still the world’s fastest fully automated jumbo caster and produces the most consistent jumbos with minimal dross.

Spectrographic specimens from mine samples

Lewis Australia’s laboratory facility automatically prepares specimen in test tubes for spectrographic analysis from up to 500 blasthole samples a day.

The facility processes in accordance with current best practice sampling theory. Samples are tracked throughout the facility and all processing information is retained. The processes are flexible, with full access to the programming code to allow for future changes.

Industrial robots handle the samples in trays, buckets, tumblers, cups, flasks and test tubes. Containers used are automatically cleaned for re-use within the facility for the next sample.

Feasibility studies for the mining sector

Lewis Australia offers a range of feasibility studies for the mining industry.

We can investigate a number of options for our clients, before providing a recommended direction and budget price appraisal to assist project teams to apply for capital approval.

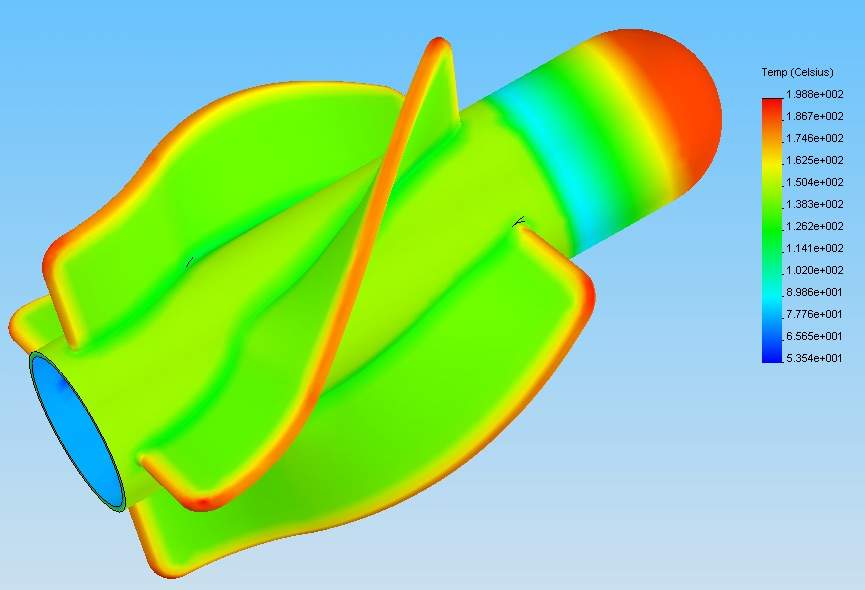

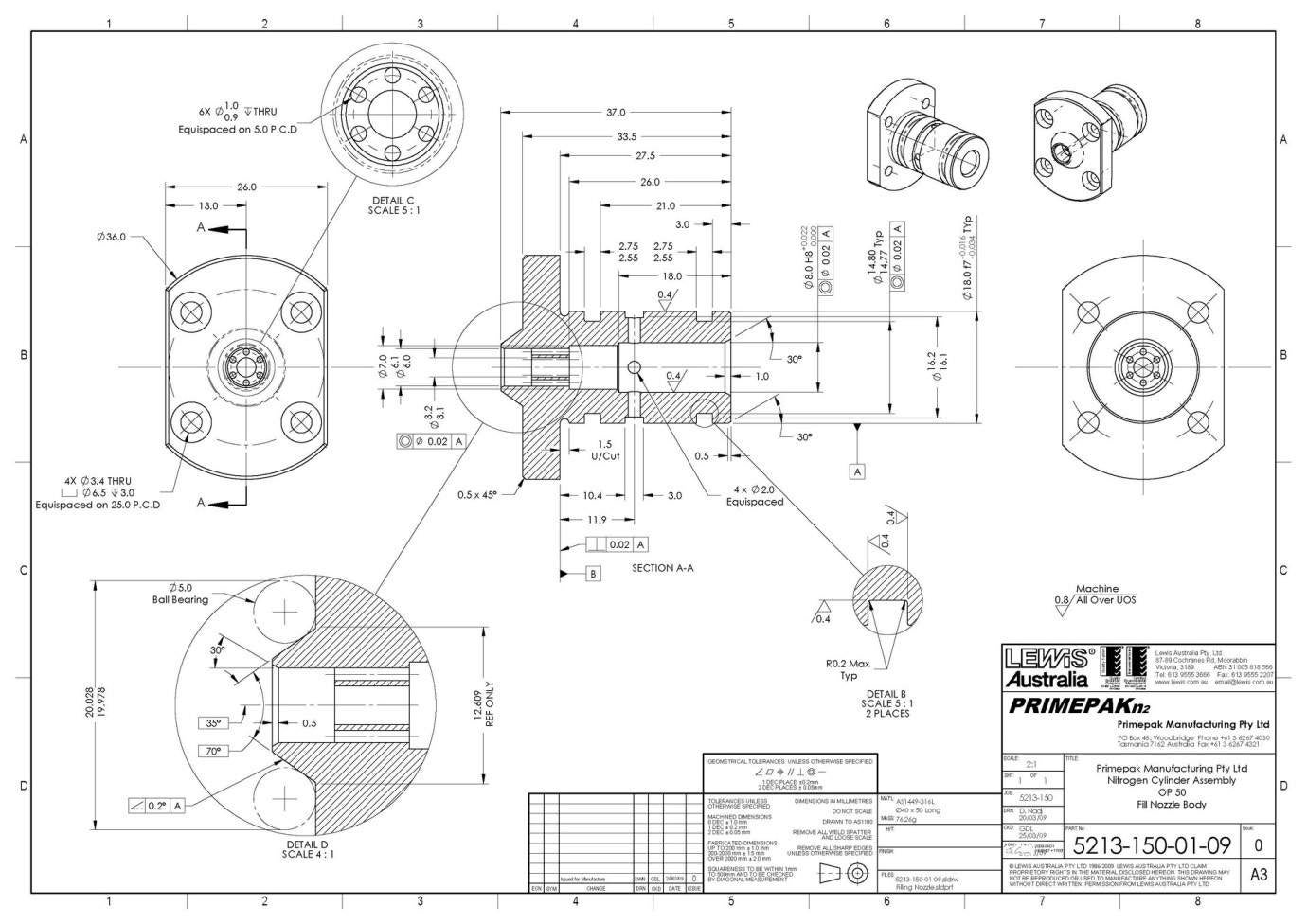

As part of these studies, Lewis Australia can also perform finite element analysis (FEA) and simulations.

About Lewis Australia

Lewis Australia has a reputation for consistently providing a dependable client service; highly productive, quality-built equipment; and on-time delivery

Our focus on high-quality engineering ensures that our equipment meets or exceeds our client’s expectations.

Please let us consider solutions to your production or maintenance problem by completing the enquiry form below.