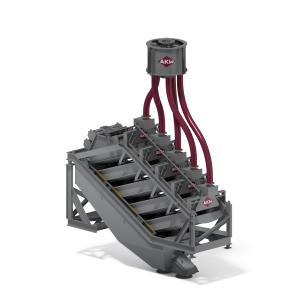

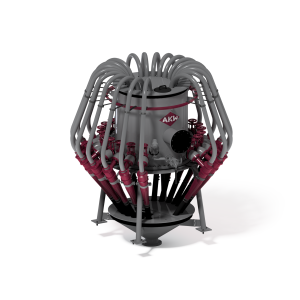

Spirals AKA-SPIN: for gravity separation of minerals

AKA-SPIN spirals are used to separate materials (60 μm – 2 mm) according to their different densities.

Principle of Operation

The slurry is fed into the spiral from the top and moves down by gravity. A transverse flow is superimposed on the main flow downwards.

This combination results in the separation of the particles contained in suspension, depending on their density. Particles with a lower specific gravity are concentrated in the outer areas of the flow. Particles with a higher specific gravity are directed towards the spiral axis.

Design Features and Client Benefits

- Separation of up to 3 fractions: heavy, middling and light density particles

- Wear resistant polyurethane coating of the spiral body

- Light weight and robust design

- Spirals can be designed to fit into columns and banks