Agitators from SLFC are used to create a controlled uniform flow pattern. This ensures that all of the tank contents are kept in motion and that the tanks are not left unmixed. The best way to achieve this turnover is to use an axial flow impeller that discharges downward towards the vessel bottom.

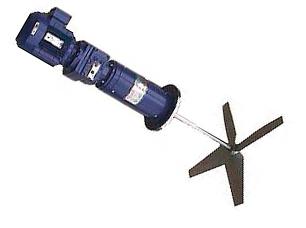

A pitched blade turbine impeller has traditionally been used for blending and solids suspension; however the discharge flow can be spread by more than 45°. This leaves a low velocity area under the shaft where agitation is difficult or solids can settle. The Chemplant RTF4 creates an axial flow pattern with a very even velocity profile across the impeller. This minimises any low velocity areas and ensures the tank contents are quickly and thoroughly mixed. At the same time the RTF4 has the lowest power consumption for a given discharge velocity, which can give energy savings of up to 60%.

The greatest benefit of the RTF4 is the low torque requirement for a given amount of flow. Low torque means that the drive and shaft sizes can be minimised and the service factor on the drive maximised. This results in extended agitator life and normal operational spares requirements will be reduced. The RTF4 has one of the lowest torque requirements of any impeller which equates to significant capital and running cost savings.