Autonomous Solutions, Inc (ASI) is a world leader in original equipment manufacturer (OEM) independent mining vehicle automation solutions.

Autonomous haulage to improve productivity and safety at mine sites

Vehicle automation technologies such as ASI’s autonomous haulage system help mining organisations to dramatically improve productivity while simultaneously reducing costs.

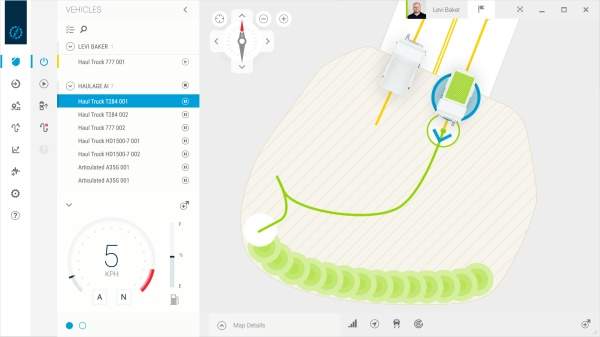

Through work with global mining majors, ASI has developed a highly scalable, client / server-based autonomous haulage system called Haulage AI, which allows one user to manage multiple haul trucks continuously tasked in a haulage system.

This one-to-many relationship improves overall productivity by targeting and overcoming cost drivers such as unscheduled maintenance, vehicle under-utilisation, fuel inefficiencies, personnel issues (shift changes, human error, etc.) and vehicle or personnel safety incidents.

Cost-effective entry into mining machine automation

Vehicle automation is one of the key innovations that leads to success for mining operations, but the significant investment in new robotic-enabled vehicles or retrofits of existing fleets can be prohibitively expensive.

ASI’s teleoperation solutions allow mining companies to validate the effectiveness of robotic technology on a small number of vehicles without major upfront investments.

Autonomous Solutions fits teleoperated dozers, excavators and haul trucks with vehicle robotics, which are controlled from a remote command station. One operator is able to control one vehicle with the assistance of joysticks, driver assistance software and cameras.

Teleoperation enables mining companies to ease into or test automation technologies, as well as improve safety by removing operators from potentially hazardous environments.

Remote control equipment for mining activities in dangerous or unstable terrain

In April 2013, Bingham Canyon mine experienced a catastrophic landslide that poured nearly 165 million tonnes of debris down the side of the mine. The slide buried millions of dollars of equipment in the pit and stopped operations. In addition, the dangerous slope and unstable terrain made clean-up efforts difficult.

Representatives of Kennecott Utah Copper Company / Rio Tinto approached ASI to develop a remote control solution that would allow remediation to commence on the most dangerous areas. Excavators equipped with ASI remote control technology enabled Kennecott operators to spearhead the clean-up by moving millions of tonnes of material on the most dangerous slopes from a safe distance.

This is just one example of how remote control mining vehicles can help enhance safety in mines. Remote control and teleoperation equipment is an inexpensive entry point into mining vehicle automation.

Mine safety systems and obstacle detection sensors

Mine managers must understand how changes made to improve short and long-term productivity affect the overall safety of both equipment and personnel.

ASI provides productivity-enhancing automation technologies that are specifically designed with a multi-tiered safety approach, including hardware, software and sensors. Each vehicle is equipped with:

- An onboard emergency-stop (e-stop) button that immediately halts all vehicle functions when activated

- Onboard computer systems that continuously monitor and run diagnostics on more than 100 system areas searching for anomalies

- ASI’s Mobius command and control software, which has proximity and choreography features to prevent vehicle collisions between autonomous vehicles, manned vehicles and known obstacles in a mine

- Obstacle detection sensors such as ASI’s Forecast 3D laser system that scan for unknown obstacles such as falling debris, human or animal traffic and more

Fully autonomous mining vehicle solutions

ASI’s automation system offers a unique upgrade path from teleoperated or remote controlled mining equipment to fully autonomous machinery.

Teleoperated or remote control equipment represents a cost-effective entry point into automation for mining companies; however, they do not provide the significant productivity gains mining companies require.

ASI’s mining clients can upgrade from their base remote control or teleoperated solutions to fully autonomous vehicles or haulage systems where significant economies of scale can be realised. This is accomplished through ASI’s universal robotic technology and client / server-based software system.

The same technology that is used for a remote control system is also used for fully autonomous vehicles, making upgrades both possible and cost-effective.

To learn more about how ASI’s autonomous mining technologies can benefit your organisation, please visit the company website or submit an enquiry form.

About ASI

With more than 14 years of supplying autonomous mining technologies to clients in the mining, military, agriculture and automotive industries, ASI is uniquely equipped to provide proven robotic hardware and software systems that convert existing equipment into autonomous haul trucks, articulated dump trucks (ADT), dozers, or excavators.

ASI is Anglo American’s partner for autonomous haulage.