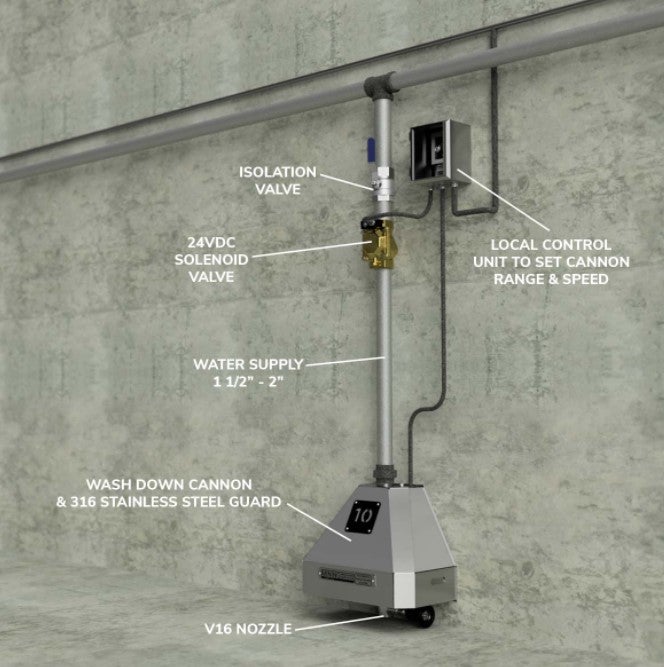

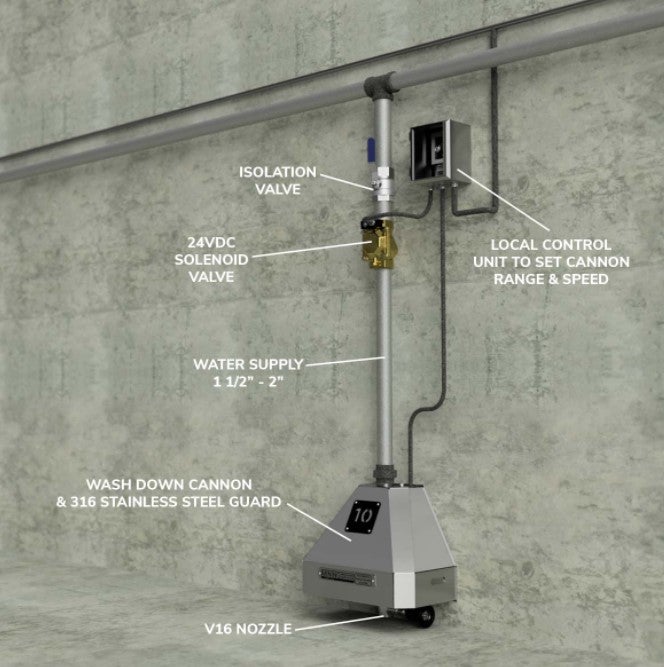

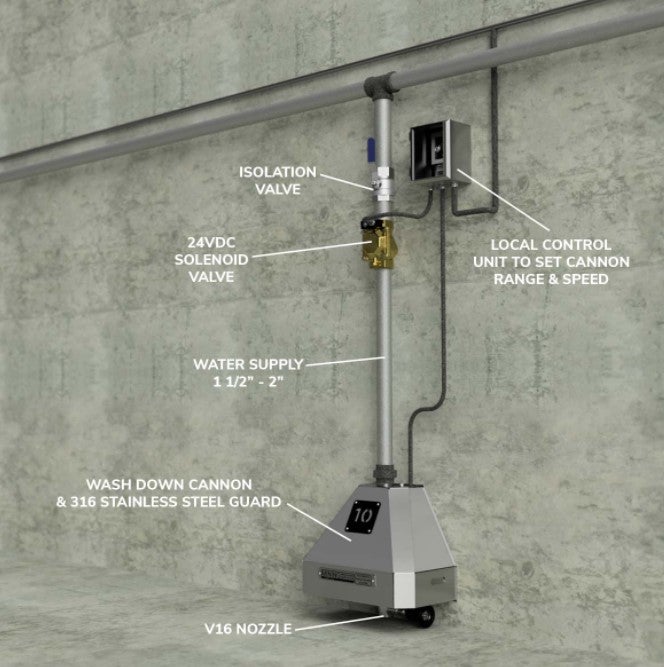

The Automatic Wash Down System uses our innovative cannon unit to clean conveyors with laser precision. Our system is designed to cut down on live manhours and help you run a more efficient operation.

Power supply & control unit

Power supply

The system is powered by a 240VAC/24VDC 20A power supply housed in a 316 stainless steel IP67 rated enclosure. The unit features a local isolation switch and a power indicator light to confirm successful isolation.

Control unit

The control unit is housed in a 316 stainless steel IP67 rated enclosure and can support up to 6 brushless 24VDC wash down cannons and solenoid valves. Cannon oscillation limits and speeds are set via the touch screen inside the enclosure.

Control unit integration

The control unit can be integrated into mine control systems by connection to the dedicated digital inputs and outputs. Standard systems have six digital inputs that correspond to each wash down cannon. When the digital information is received, the cannon will begin to oscillate between the predetermined set points, and the associated solenoid valve will operate. The system has eight digital outputs, and each cannon has a “running” signal. This can be set up to notify control with an “obstructed alarm” if the signal is not received in (x) number of seconds once the cannon has been started. There are also digital outputs for “Emergency stop activated” and “power supply OK”.

For wash down systems not integrated into the mine control system, a local control unit can be supplied with essential timer functions, and local start/stops. These units are supplied as per customers requirements.