ExploSpot Systems develops explosion suppression technology to protect personnel and machinery in the mining sector.

Our technology became so effective that the South African Mine Health and Safety Council explored the use of these suppression systems in coal mining applications.

A methane gas and coal dust mitigation control system was developed in cooperation with mining entities such as SASOL, Anglo American Coal and Trans Natal Coal, as well as the support of the Council for Scientific and Industrial Research (CSIR).

Our Explospot® automatic explosion suppression systems (AESS), also called active explosion suppression barriers, have been in operation since 2001. They are used during mining operations to protect personnel, machinery, and operations.

Since its founding in 1994, Explospot has evolved to become an original equipment manufacturer (OEM) of pure AESS and automatic fire suppression systems (AFSS), as well as dust suppression systems and solutions.

Machine-mounted active explosion barriers

Explospot’s machine-mounted active explosion barriers are automatic explosion suppression systems installed on underground mechanised cutting machines. Designed for coal applications, they stop methane gas and dust explosions at the cutting face. Designed for methane gas explosion mitigation and suppression applications, these systems require an extremely reliable and fast detection and activation mechanism.

Our optical detector not only identifies an explosion in two milliseconds and initiates a suppression reaction within 7ms-10ms.

Due to the unique double-activation mechanism, the suppression activation is the most reliable mechanism available. The ultra-fast reaction of the system, combined with the appropriate suppression material, will ensure that temperature, pressure and toxic gas development will maintain below human tolerance levels. Therefore, it ensures survival during a methane gas and/or coal dust explosion at the cutting face.

These suppression systems are designed to be used as close as possible to the cutting face on continuous miners, roadheaders, auger machines, longwall shearer and chocks. We have also supplied pre-engineered systems for Komatsu, Sandvik, Eickhoff, Caterpillar, Sony and other manufacturers.

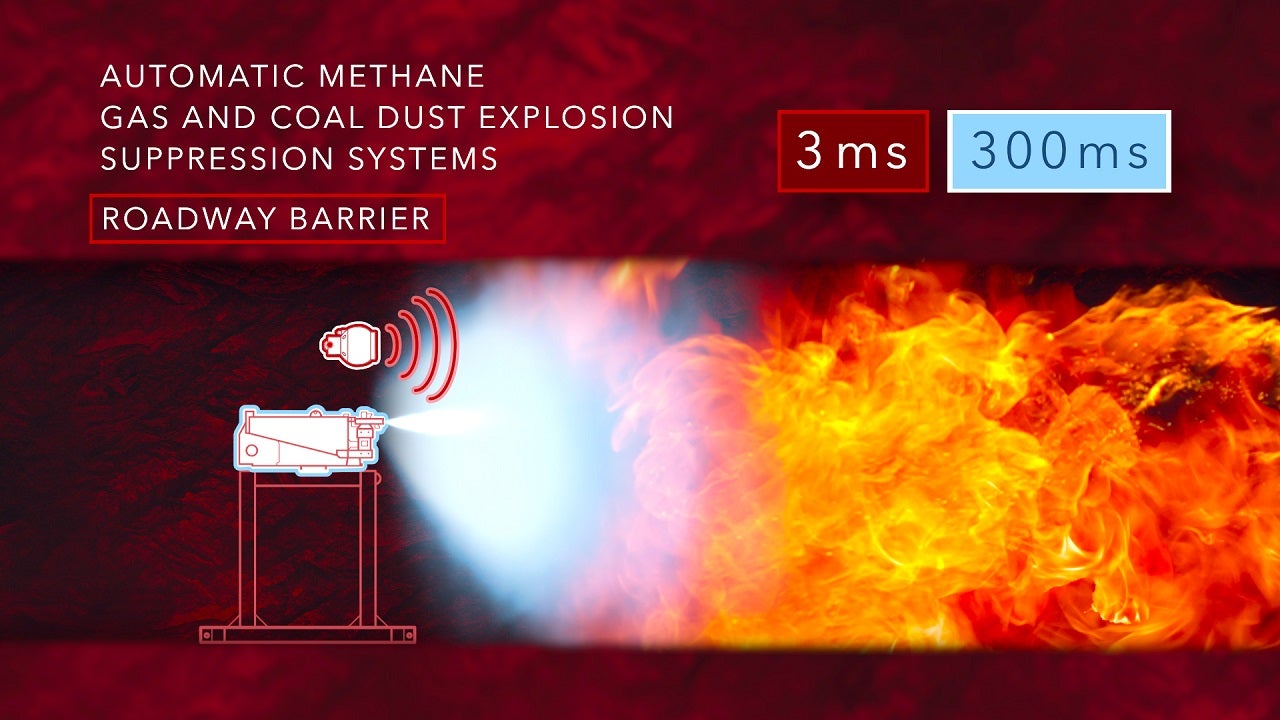

Active explosion barriers for roadways

Explospot’s automatic explosion suppression systems function in much the same way as the machine mounted active explosion barriers.

The difference between these two barriers is the location of the ignition source. While a machine-mounted active explosion barrier will be as close as possible to the ignition source (cutting face), the active roadway explosion barrier will be located to the nearest conveyor roadway section. These systems are classified by most mining legislation to replace bagged stone dust barriers.

The active roadway barriers are commonly installed behind a feeder breaker, on a conveyor or as standalone/autonomous systems within a roadway.

Automatic conveyor fire suppression systems

Explospot’s automatic conveyor fire suppression systems are used to detect and suppress fires that occur on a conveyor belt. They can be pre-engineered as autonomous standalone systems or part of an integrated solution.

All systems use eco-friendly suppression solutions such as aqueous film-forming foams (AFFF) or pure water mist fire suppression. These automatic conveyor fire suppression systems also cater to a gas scrubbing mist barrier that ensures that no toxic gasses escape along the airstream.

Ember detection solutions

As part of the 20-year fire detection R&D work conducted, Expospot has developed an ember detector capable of locating ember coal on components such as a moving conveyor belt.

These detectors assist mining operation as early warning units indicate the potential and severity of reactive coal being mined.

Dust suppression systems

Explospot Systems manufactures non-electrical, airless and water-hydraulic dosing systems for various mining applications.

They aim to dose binding and foaming agents into the water supply used to wet the material during loading, off-loading, crushing and moving material.

These systems can dose as little as 0.4% and up to 6% additive into the water. Due to the proprietary dosing pump’s pressure rating of up to 20 bar, the systems can be used inline of the mining water supply without additional mechanical pressure reducers.

A further advantage of the higher pressure rating these systems is that they can be used with various nozzle configurations. The systems have been designed and tested in various underground and surface mining environments.

They have also been installed on continuous miner flight chains and feeder breakers to reduce the respirable dust by 30%-60% along the entire material handling process, depending on the application and additive used.

General advantages of applying environmentally friendly additives to water when managing dust include:

- Reduce water usage and surface tension

- Increased contact surface: up to 6m² when using foam and up 200m² for 1l of water when using misting nozzles

- A residual effect for whole and sustainable dust control

- Does not interfere with mining operations

- Easy maintenance and installation

Road stabilisation solutions

Global mining departments have recognised that there are significant challenges when trying to control dust when either using water alone (short-term solution) or using toxic bitumen-based products.

Explospot’s road stabilisation and dust control products focus on delivering cost-efficient sustainable and optimal road conditions. They are also environmentally friendly and easily applied on any road surface.

Global research combined with studies conducted together with our partners and customers have proven that treating or stabilising unpaved / gravel roads increase all plant, machinery and vehicle tyre lifespan by up to 50%. The increased vehicle traction also reduces fuel consumption by 5%. The added safety on the roads due to the maintainable traction is a priceless advantage.

Explospot’s road stabilising products include:

- Dustcrete is a highly popular dust palliative due to the ease of application on all road conditions, and a higher-performance standard compared with other products available, due to the high solid content and water-resistance of the product.

- Polysol is mainly used in conditions where water usage and availability are a problem. The product creates a long-lasting road surface, which only needs a maintenance spray dosage every six months to a year. Due to these low maintenance requirements, there are dramatic cost savings related to any road maintenance, water, increased tire life span, lower fuel consumption and no road surface weathering due to rainfall.

- Pitsol is a natural binding agent, which is highly cost-effective when applied inside open-cast mining areas. Pitsol reduces the need of a constant application of water to roads inside the pit to control dust throughout the day, by binding dust and aggregate material in the short term and keeping the roads damp for longer.