Mining-Technology speaks to GeoAssay CEO Feliciano Herrera about their partnership with Nucomat.

Tell us more about GeoAssay

GeoAssay is a service company for the mining sector, for this, it has three chemical laboratories located in the centre and in the north of Chile, where large mining is concentrated. Among the services, sample preparation and chemical tests such as Au – Ag – Cu – Mo (metal base) applied to mineral samples stand out.

Codelco, BHP, AngloAmerican, among others, stand out among its main clients. To demonstrate the quality of its service, GeoAssay has leading-edge automated technology, robotic technology and highly qualified personnel in its laboratories. All of its applied technical and management procedures are based on a quality management system based on the accreditation of Standard 17.025, which allows to us demonstrate our technical competence to many clients.

When and why did you choose Nucomat as an automation supplier?

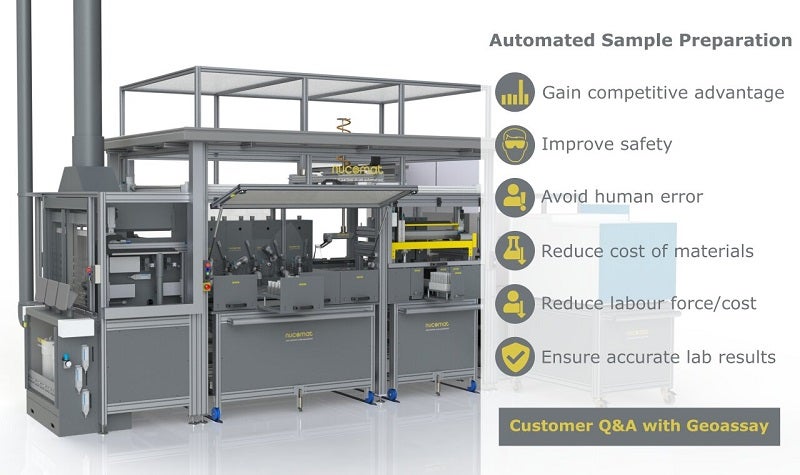

Given the new economic scenario and the changes in technologies, GeoAssay incorporates new automated and robotic technologies in all its laboratories, selecting to its strategic supplier Nucomat, because this one has all the technological innovation necessary for the implementation of chemical analysis techniques that break classical paradigms, to new industrial revolution necessary nowadays to be a competitive company in the market of testing laboratories for our minerals.

How has Nucomat’s automation solution affected your operations?

In a very positive way, in the first place, the occupational safety indicators were decreased, in addition, mistakes due to human non-intervention in the routine tasks of chemical analyzes were decreased, and on the other hand, costs in raw materials such as mineral acids used in the pre-treatments of the samples were also reduced. There was also a decrease in technical personnel, which turn into lower labor costs.

Have there been any notable projects that benefited from your partnership?

The main project achieved with the new automation technology was Codelco Chile for its four large mining companies located in the north of Chile, such as Chuquicamata Mine, Ministro Hales, Rodomiro Tomic, and Gabriela Mistral. On the other hand, the Codelco EMSA Exploration Area was added to the project. In addition to this, new jobs were obtained from other mining companies located in the north.

Has your automated infrastructure been an added value towards your customers?

The new Nucomat automation incorporated into GeoAssay has meant recognition of our institutions such as CORFO, Fundación Chile, etc. Linked and committed to all the mining work of seeing our GeoAssay laboratory as a world-class laboratory, this has undoubtedly been received by our clients from the mining companies in an important sum for the entire value chain in their processes, mainly from copper production, given that it received from us a robust and traceable result in the evolution of its geological mining reserves.

Has your automated infrastructure made a difference during the COVID-19 crisis?

We have advantages over our competitors during the pandemic because we can perform more analysis with fewer people. When you have problems with people getting sick or when the people got the virus and must enter lockdown, an operational shift is required. If you have wetchem systems and mini dispensers running, then you can go ahead and give the support that the mining companies need. In other words, if you have automation solutions from Nucomat implemented in your laboratories, you can be sure that you have a business continuity plan in action for your operational support.