The Witwatersrand Basin Project is an underground gold mine being developed in South Africa by Australian exploration and development company West Wits Mining (West Wits).

The project is being implemented in five stages. The first stage of development focuses on the development of the Qala Shallows, which is estimated to account for approximately 40% of the total planned output of the project. The remaining stages include Main Reef Package (stage two), Bird Reef East (stage three), Bird Reef Central (stage four), and Qala Deeps (stage five).

West Wits’ mining right application for the underground mining project was approved by South Africa’s Department of Mineral Resources and Energy in July 2021. A definitive feasibility study (DFS) for the development of the first stage (Qala Shallows) was completed in September 2021.

The Qala Shallows underground mining project is estimated to produce at a steady rate of 53,000 ounces (oz) a year from the fourth year of operations for a ten-year period before a gradual depletion of the reserves. The first stage is expected to have a life of mine (LOM) of 17 years while the overall project’s LOM is estimated to be 25 years, which includes 22 years of production.

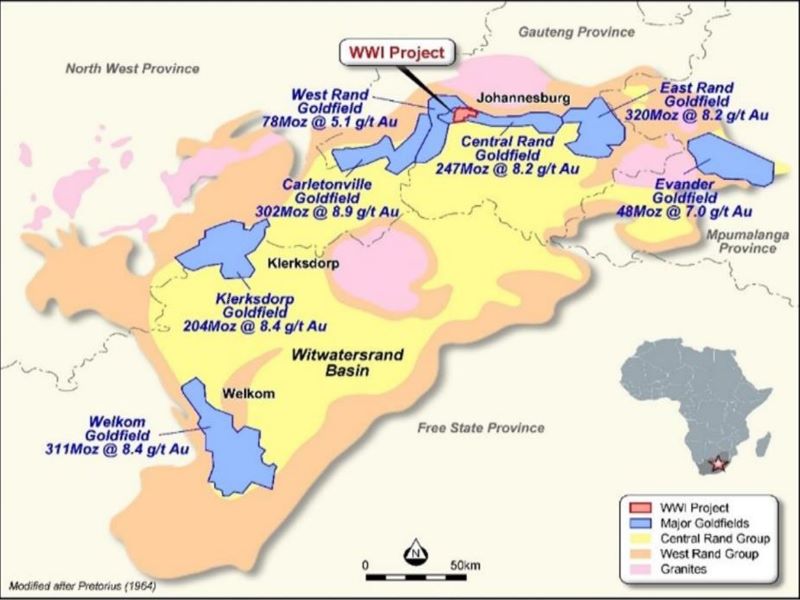

Witwatersrand Basin project location and geology

The Witwatersrand Basin project is located approximately 15km west of Johannesburg, Gauteng Province, South Africa.

The basin comprises a thick sequence of rocks known as Witwatersrand Supergroup, which consists of the lower West Rand Group and the upper Central Rand Group.

The West Rand Group is dominated by shale with subordinate quartzite while the Central Rand Group hosts most of the gold-bearing conglomerates. The Kimberley Reefs of the Central Rand Group are expected to be the target area for mining during the first stage.

Witwatersrand Basin project reserves

The total measured, indicated, and inferred resources at the Witwatersrand Basin project are estimated at 25.91 million tonnes (Mt), graded at 4.26g/t of gold, as of July 2021. Contained gold is estimated to be 3.55 million ounces (Moz).

The proven and probable mineral reserves at the Qala Shallows are estimated at 3Mt graded at 2.58g/t of gold and containing 277,600oz of gold.

Mining at Witwatersrand Basin project

The scoping study of the Witwatersrand Basin project considers the use of conventional breast mining in shallow dipping areas and mechanised long-hole open stoping mining in steep dipping areas.

The mining operations at the Qala Shallows will involve conventional underground methods of breast stope mining in an underhand configuration. Strike dives will be used to access the mining stopes developed on the K9B Reef horizon. The primary access to the underground mine will be via a decline system from the surface from the existing Qala Adit box cut.

The majority of the first stage of mining operations will be conducted in a large unmined block located to the east of the property. The pillar remnants on the western side of the mining area above the flooded historical workings will also be mined.

The DFS outlines the use of standard underground mining techniques utilising hand-held drills mounted on jack legs to extract ore from the stope blocks. The mine plan includes drill rigs, load, haul, dump trucks (LHDs), and articulated dump trucks (ADTs) for the development of the strike drives and decline.

Processing at Witwatersrand Basin project

The ore produced from the project is planned to be treated at one of the existing plants located nearby, on a toll treatment basis. The ore will be processed at a standard carbon-in-pulp (CIP) processing plant.

The run-of-mine (ROM) ore will undergo grinding in a semi-autogenous grinding (SAG) mill fitted with cyclone clusters. The ground ore will be transferred to thickeners where it will be mixed with a flocculant and lime before being transferred to the leach agitators. The ore will be mixed with sodium cyanide in the leach agitator and transferred to CIP tanks.

The loaded carbon will be transferred to an acid wash tank where hydrochloric acid will be introduced. The acid-washed carbon will be transferred to an elution column, which will feed the electrowinning cells where gold from the loaded carbon will be deposited onto cathodes.

The gold sludge deposited on the cathodes will be collected periodically and transferred onto the filtration and drying circuit to produce the final dried gold sludge.

The gold sludge will be dispatched to Rand refinery, an integrated single-site precious metals refining and smelting complex in South Africa.

Contractors involved in Witwatersrand Basin project

The definitive feasibility study for the project was prepared by Bara Consulting, a global mine engineering firm. The company also conducted the scoping study for the Witwatersrand Basin project.