The Vittangi Anode project in northern Sweden will be developed as an open-pit mine by Talga Resources.

The definitive feasibility study (DFS) for the project was completed in July 2021. The project is anticipated to have a mine life of 24 years with an estimated development capital cost of $595.8m. The front-end engineering and design (FEED) for the Vittangi Anode project was completed in April 2024.

The project includes a graphite anode refinery capable of producing 19,500tpa of Talga’s natural graphite anode product, Talnode®-C. The strategic move aligns with Talga’s vision to establish a European battery anode production and graphene additives supply chain.

The ground-breaking ceremony for the refinery was held in September 2023, marking a milestone to be Europe’s first commercial anode production facility for electric vehicle lithium-ion batteries.

Trial mining operations were conducted in 2023 while the ground-breaking ceremony for the anode refinery in Lulea was held in September 2023.

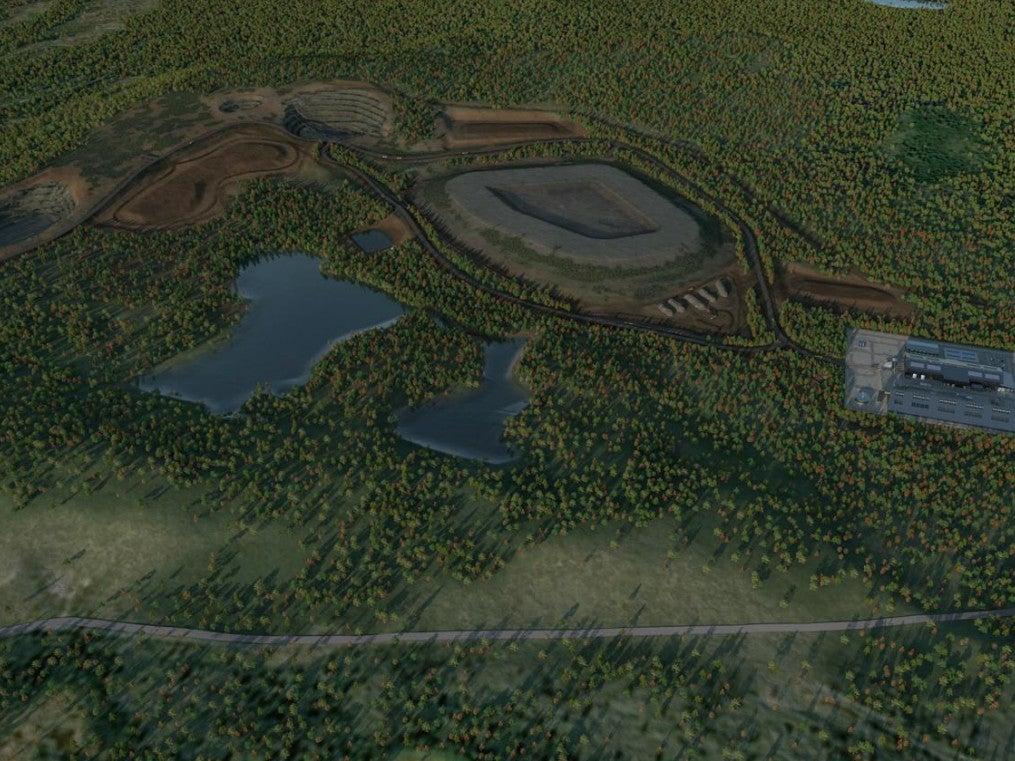

Location of the Vittangi Anode project

The Vittangi Anode project is located in Norrbotten County, Sweden.

The graphite deposits are situated 10km north-west of Vittangi and 20km north-east of LKAB’s iron ore mine at Svappavaara and are accessible via established road networks.

Geology and mineralisation of the Vittangi Anode project

The region’s bedrock geology comprises greenstones, metasediments, and metadolerites, which belong to Vittangi Greenstone Group.

The project’s mineralisation features two sub-vertical, lithologically continuous units of fine-grained, high-grade graphite, with graphitic carbon content ranging from 10% to 46%. The surrounding geology includes mafic volcanoclastics and tuffaceous units, with a mafic intrusive forming the footwall.

Reserves at Vittangi

The Vittangi Anode project’s graphite reserves are estimated at 36.9 million tonnes (mt), with a graphitic carbon (Cg) grade of 23.1% and 8.5Mt of Cg in contained mineral of June 2023.

Mining method

The mining operation at Vittangi will employ conventional open-pit methods, including drilling, blasting, loading, and hauling.

The straightforward structural nature and shallow depth of the deposit will allow the use of conventional drill and blast techniques, with small-scale truck and shovel equipment facilitating the development.

Mining operations will be conducted in a series of four open pits with operations commencing in Pit 4 area. Drilling and blasting will be carried out on 5m benches, while material loading will be handled in two flitches with a height of 2.5m-3.0m.

The pits will gradually merge into a single larger open pit from Pit 4 through to Pit 1 via a series of pushbacks and extensions.

Ore processing

The ore recovery process will consist of crushing followed by grinding, rougher floatation, regrinding, cleaner floatation and concentrate dewatering to produce a high-grade graphite concentrate. The concentrate will be refined further for utilisation in the anodes of lithium-ion batteries.

The crushing process will be conducted in three phases utilising portable machinery to reduce the ore size to <35mm. The initial, secondary, and tertiary crushing stages will take place proximate to the raw ore stockpile area, situated 250m westward of the processing plant structures.

The crushed ore will be fed to a mill for grinding prior to rougher flotation. The ore slurry from the grinding circuit will undergo an initial rougher flotation stage.

It is anticipated that between 55% and 60% of the material will progress as the primary concentrate. The material will be reground and subjected to five cleaning stages to produce a concentrate with varying degrees of purity.

The cleaning circuit will be equipped with a cleaner tail recycle from which the final cleaner tails will exit. The rougher and cleaner tails will be dewatered in a common thickener, followed by filtering to produce a moist filter cake.

The final concentrate product will be transported to Talga’s anode refinery for further processing to produce battery grade (>99.9%) graphite product as part of the anode production process.

Site infrastructure at Vittangi Anode project

The mining operation is situated 5km along a pre-existing unsealed road, which links to the state’s road network. Plans include upgrading the road to a dual carriageway to accommodate increased traffic.

The refinery is located in the Lulea Industrial Park, which is under development adjacent to the Lulea port. The site is well-connected to Vittangi via the state highway. Grid connection for the Lulea refinery will be established and managed by Lulea Energi.

The mine will be integrated into the regional grid, which is powered by renewable hydroelectricity, necessitating the construction of a new power line from Svappavaara to the mine’s substation.

Water supply for the concentrator will include the recovery of groundwater inflow, pit seepage, and recycled water. Additional water will be sourced from Hosiojärvi Lake if necessary, while the refinery will utilise water directly from the Lulea River.

Sustainability features

In 2020, ABB and Talga Group entered a memorandum of understanding (MoU) to explore electrification strategies, focusing on ABB Ability™ eMine solutions.

ABB is set to assist Talga in achieving its aim of zero-emission, sustainable battery graphite mining and processing by providing industrial automation, electrification expertise, and advanced production and process control solutions for Talga’s initial operations.

Contractors involved

Worley (UK), a global engineering and consulting company, and Sweco Engineering (Sweden), a leading engineering and architecture firm based in Europe, were responsible for the process plant design, and non-process infrastructure (NPI), including construction planning, and cost estimation.

Golder Associates, a premier global consulting and engineering firm, provided the ore reserve statement and mine design, as well as the design for the integrated waste facility.

Mannheimer Swartling, a leading law firm, provided the environmental legal and permitting advice.

NYAB, a local contractor, was engaged to complete the refinery groundworks.