The Vares silver project is a proposed underground mining project in Bosnia and Herzegovina. It is owned and operated by Adriatic Metals, a UK-based minerals exploration company.

The project consists of two high-grade polymetallic deposits, namely the Rupice underground deposit and the Veovaca open-pit deposit. A pre-feasibility study (PFS) for the project was released in October 2020 while a definitive feasibility study (DFS) was completed in August 2021.

The DFS envisions the development and mining of the Rupice deposit, which hosts ore of higher value. The development of Veovaca will be deferred until further metallurgical test work and engineering. The current mine plan envisions a mining life of ten years.

Vares silver project location, geology, and mineralisation

The Vares silver project is located in Vares within Zenica-Doboj Canton in Bosnia and Herzegovina. The project concession is spread across approximately 41km².

The host rocks at the Rupice deposit include limestone, dolostone, and calcareous and dolomitic marl of Middle Triassic age. The deposit also hosts mostly fine-grained siliciclastic rocks, including cherty mudstone, siltstone, and fine-grained sandstone. A brecciated dolomitic unit forms the main high-grade mineralised horizon.

The mineralisation at the Rupice deposit comprises pyrite, galena, sphalerite, barite and chalcopyrite with gold, silver, boulangerite, tetrahedrite, and bournonite. The sulphide mineralisation has a strike length of 650m and a thickness of 20m. The polymetallic mineralisation is open to the north and continues down-dip to the south of the deposit.

Vares silver project reserves

The probable mineral reserves at the Vares silver project were estimated at 7.3 million tonnes (Mt) grading 202g/t of silver, 5.7% zinc, 3.6% lead, 1.9g/t of gold, 0.6% copper, and 0.23% tin, as of August 2021.

Mining methods at the Rupice mine

The Rupice mine at the Vares silver project will be operated as an underground mine using longitudinal long-hole open stoping (LLOS) above the 1,065 level. The zone below this level will be mined using the transverse long-hole open stoping (TLOS) method. The LLOS method will be employed to extract ore from areas where the thickness of the ore zone is less than 20m, while TLOS will be used in areas with thicknesses of more than 20m.

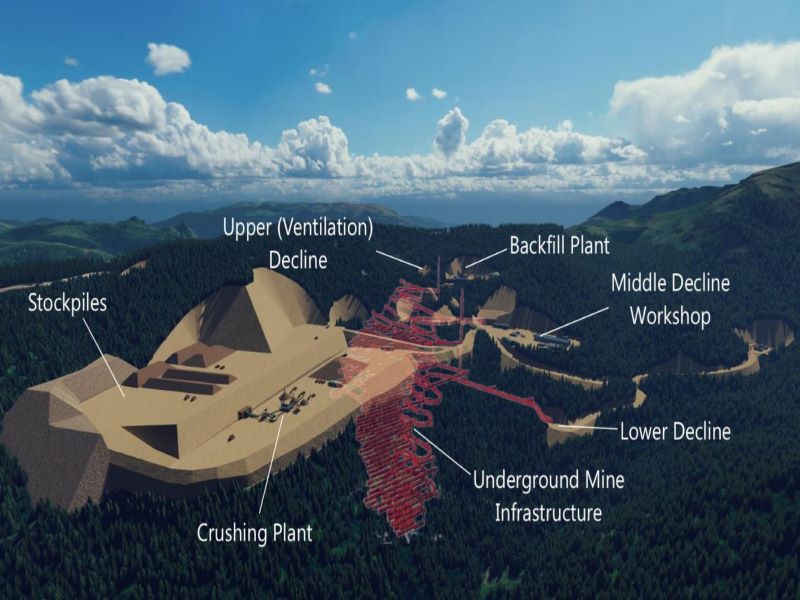

The underground working areas will be primarily accessed via two separate declines developed from the surface with a width of 5.5m and a height of 5.5m. A maximum gradient of 14% will be used to develop the main return airway and middle access decline while the lower access decline will have a maximum decline gradient of 16%.

Spaced at 20m vertical intervals, each sub-level will have level access drives connecting the ramps with the 5m-wide, 5.5m-high footwall drives, which will be developed 25m away from the orebody.

The transverse longitudinal stopes will be accessed via the lower 12 sub-levels while the access to the longitudinal long-hole stopes will be from the upper five sub-levels.

The blasted material will be loaded and hauled to the surface via the internal ramp and decline, following which it will be stocked in run-of-mine (ROM) stockpiles meant for different grades.

Mineral processing at Vares silver project

The Vares processing plant will have a designed throughput rate of 800,000tpa. It will be built on a brownfield site that hosted a previously operated processing plant for the historical Veovaca open-pit mine.

The ROM ore will undergo crushing in a three-stage facility at the Rupice surface infrastructure site, on the ground above the Rupice underground mine. The crushing facility will include a single-toggle jaw type primary crusher, and secondary and tertiary cone crushers to produce crushed ore product of 7mm.

The crushed ore will be trucked to the Vares processing plant located approximately 24.5km away, for further grinding. The ball mill and cyclones are designed to reduce ore from an 80% passing size of 7mm to 40µm. The flotation circuit features silver-lead flotation and zinc flotation circuits.

The silver-lead flotation stage will recover a silver-lead concentrate, which will feed the silver-lead regrind circuit comprising a cyclone cluster and stirred horizontal regrind mill. The tailings will be conditioned and then sent to the zinc flotation circuit.

The cyclone overflow from the silver-lead regrind circuit will be transferred to the silver-lead cleaner circuit, while the underflow will be sent to the regrind mill by gravity. The concentrates will undergo three-stage cleaning in the silver-lead cleaner circuit before being moved to the silver-lead concentrate thickener. The first cleaner tailings from the circuit will flow to the zinc cleaner flotation circuit.

The final concentrate handling circuit will dewater the silver-lead and zinc concentrates by thickening and filtration processes before they are loaded out for shipment.

Infrastructure of the Vares silver project

The processing plant site can be reached from the main sealed road (R444), which connects Vares to the capital city of Sarajevo. A secondary sealed road from the R444 runs east to the site.

The power required for the Rupice surface infrastructure, underground mine, backfill plant, and crushing plant will be provided via a new, buried 35kV power line. The line will run from Vares Majdan regional substation to the new Rupice substation. A 35kV overhead line runs from the historic site to the processing plant.

The water supply required to meet the requirements of the surface infrastructure will be sourced from the Studenac stream near Pogar via a new pump and a 5km-long pipeline.

The silver-lead and zinc concentrates will be transported 6km to the Vares Railhead facility for transport to Ploce Port located on the Croatian Adriatic coast, near the mouth of the Neretva River.

Financing for Vares silver project

Adriatic Metals announced a project finance package of approximately $244.5m proposed for the construction of the Vares silver project in October 2021. The package comprises debt financing and private fundraising.

The company signed a term sheet agreement with Orion Resource Partners (UK) (Orion) for a $142.5m debt financing package, including $120m in senior secured debt and a $22.5m copper stream component. Adriatic Metals also intends to raise up to $102m in equity.

Contractors involved

Global construction engineering company Ausenco coordinated the 2021 DFS. It provided consultancy services for the processing plant and surface infrastructure site, as part of the study. Mining Plus provided the mine plan for the Rupice underground deposit.

Slurry systems designer Paterson and Cooke was responsible for the backfill plant test work and design while Wardell Armstrong International was appointed to perform metallurgical test work and study the tailings storage facility (TSF) and project-wide water balance, as part of the DFS.

Avocageotec performed the mine geotechnical works while Bluequest Resources was contracted to perform studies pertaining to concentrate offtake, marketing, and logistics.