Turnagain is one of the largest undeveloped nickel sulphide deposits in the world. It is located in northern British Columbia (BC), Canada.

Hard Creek Nickel, a joint venture (JV) formed by Giga Metals (85%) and Mitsubishi (15%), is developing the project.

The pre-feasibility study (PFS) was filed in October 2023, which estimated an operating life of 30 years. Designed to be a low-carbon nickel mine, Turnagain is estimated to require an initial capital of $1.9bn.

A feasibility study and environmental assessment are planned to be undertaken for the project.

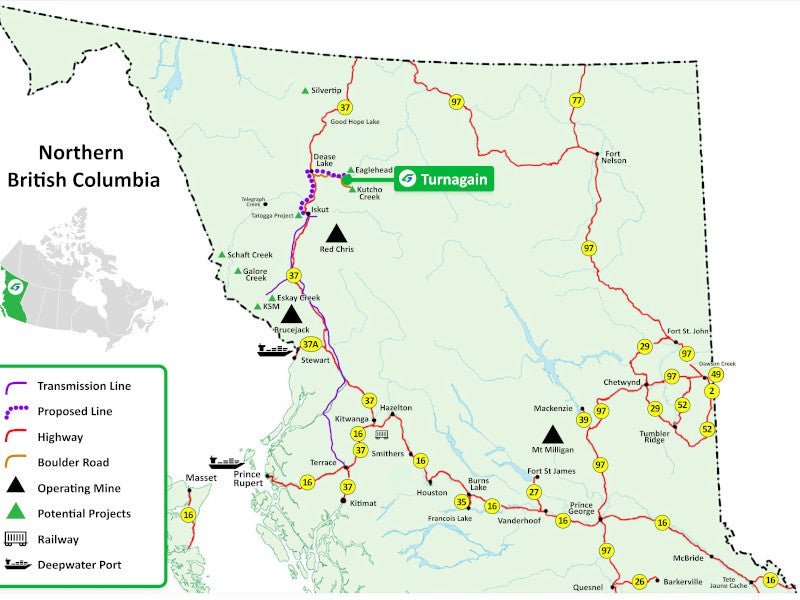

Location of the Turnagain project

The Turnagain nickel project is situated approximately 65km to the east of the Dease Lake township in the northern part of BC, Canada. It lies within the traditional territorial claims of the Tahltan Nation and Kaska Dena.

Spanning 40,069ha, the project includes 75 mining tenures, the majority of which are contiguous.

Geology and mineralisation

The Turnagain nickel project encompasses an Alaskan-type ultramafic intrusive complex, which features a central dunite core surrounded by various units such as wehrlite, olivine clinopyroxenite, clinopyroxenite, hornblende clinopyroxenite, and hornblendite.

Sulphide mineralisation is associated with metasediment inclusions and occurs in the form of pentlandite and pyrrhotite, with minor quantities of chalcopyrite, pyrite and bornite.

Reserves of the Turnagain project

The Turnagain nickel project is estimated to contain proven and probable reserves of 950.5 million tonnes (mt) grading 0.205% nickel (Ni) and 0.013% cobalt (Co), as well as containing 1.95mt of Ni.

Mining methods

The Turnagain deposit will be mined using conventional open-pit mining methods comprising drilling, blasting, loading, and hauling in 15m-high benches.

The mine plan will include a single main pit with five pushback phases and a smaller satellite pit for the adjacent Duffy zone. The overall main pit dimensions will be 2km x 1.5km.

The mining fleet will comprise electric rope shovels, wheel loaders, and 227t autonomous trolley-assist diesel haul trucks. Both trolley-assist and autonomous haulage technology will be used for the hauling fleet to minimise costs and environmental impact.

Ore processing at Turnagain nickel project

The processing facility is designed to handle 90,000 tonnes per day (tpd) of run-of-mine (ROM) material. It will process 45,000tpd during the first year.

The ROM material will undergo three stages of crushing in a primary gyratory crusher, two parallel closed-circuit secondary crushing circuits, two parallel high-pressure grinding rolls (HPGRs) circuits, and two parallel two-stage ball mill circuits to obtain a particle size of 80μm.

The ground product will be sent to a rougher floatation circuit followed by three stages of cleaner flotation to produce a final concentrate comprising 18% Ni.

The concentrate will be dewatered, thickened and pressure filtered to reduce the moisture content to 9% and stockpiled to be transported by trucks to a port facility and shipped to customers. A rail connection is also accessible at Kitwanga for domestic processing.

Site infrastructure

Access to the site is provided currently through a single-lane exploration trail that connects to the British Columbia Highway 37 and a 900m gravel airstrip. The exploration trail will be upgraded to a single-lane road for project development.

Power will be supplied by Canadian electric utility BC Hydro through a 160km-long 287kV transmission line from the existing Tatogga substation. Infrastructure costs are included in the project capital.

The facility is expected to be close to water-neutral with the use of all contact water and the collection of some catchment water at the process water pond. One freshwater supply system each will be established at the mine site and the plant site by pumping freshwater from nearby wells, which will be stored in tanks and distributed through pumping. Potable water will be obtained through groundwater wells and treated using chlorination and ultraviolet lamps.

Accommodation will be provided at an on-site permanent accommodation camp developed during the construction phase.

Contractors involved

Tetra Tech Canada, a consulting and engineering services company, was responsible for the overall PFS.

Engineering and consulting firms Kirkham Geosystems, Sacanus Holdings, BGC Engineering, and Kerr Wood Leidal Associates were also involved in the PFS preparation.

An updated technical report and preliminary economic assessment were prepared in 2020 by consulting firm Hatch with contributions from Blue Coast Metallurgy, Kirkham Geosystems, Kerr Wood Leidal, and Knight Piesold.

AMC Mining Consultants prepared a preliminary economic assessment in 2011 with contributions from GeoSim Services, Moose Mountain Technical Services, Reid Resource Consulting, Valard Construction, and Knight Piesold.