The Tumas uranium project is an open-pit uranium mining development by Australia-based company Deep Yellow Limited (DYL) in the Namibia region of South Africa.

The initial scoping study for the project was completed in January 2020. The pre-feasibility study (PFS) was completed in February 2021, followed by an enhanced definitive feasibility study (DFS) in February 2023.

The DFS is focused on developing the Tumas 1, Tumas 1 East, Tumas 2, and Tumas 3 deposits. The project will have a life of mine (LoM) of 22.5 years with potential for expansion beyond 30 years with the inclusion of additional resources.

The initial capital investment required for the project is estimated at $372m. DYL is expected to reach a final investment decision in the first half of 2024, while production is expected to commence ramping up in Q4 2025.

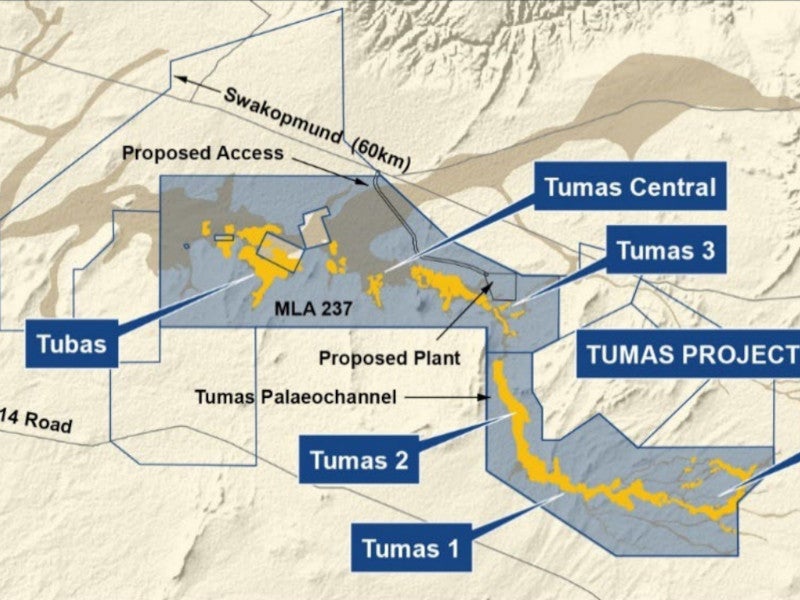

Project location of the Tumas project

The Tumas uranium project is located in the Namib Naukluft National Park (NNNP). The site lies approximately 80km to the south-east of the coastal town of Swakopmund and 80km to the east-northeast of the Walvis Bay Seaport.

Geology and mineralisation of the Namibia-based uranium project

The Tumas project comprises a series of palaeochannel/calcrete-type uranium deposits composed of poorly sorted polymictic gravels and conglomerates with minor sands and silts.

Uranium mineralisation at Tumas occurs as carnotite hosted by Tertiary and Quaternary fluvial sediments occupying narrow and steep-sided paleochannels. The deposits are associated with fluviatile environments within palaeovalleys of the Upper Cretaceous and Lower Tertiary rivers.

Reserves of the Tumas project

The Tumas uranium project is estimated to hold 88.4 million tonnes (mt) of probable mineral reserves grading 345 parts per million (ppm) U₃O₈ for a total of 67.3 million pounds (mlb) in contained U₃O₈.

Open-pit mining method

The Tumas uranium project is proposed to be developed as an open-pit mine. The mining operations will be conducted using 3m-high flitches. Waste stripping is expected to be free dig. Conventional excavators and haul trucks will be used for mining. The development of open pits will follow a single-stage design approach.

Mining operations will commence from the Tumas 3 south-east pits and progress towards the western stages of Tumas 3. Mining will continue through to Tumas 2 and end at the Tumas 1 and Tumas 1 East stages.

All mine waste from Tumas 1, Tumas 1 East, and Tumas 2, other than that required to generate the start-up pit, will be placed in the mined-out void. Waste rock from Tumas 3 will either be used to construct in-pit divider embankments, placed on ex-pit waste dumps or used as capping for filled-out tailings areas.

All process plant tailings including those from Tumas 1, Tumas 1 East and Tumas 2 will also be stored within the Tumas 3 pits.

Ore processing

The run-of-mine (ROM) ore will undergo beneficiation to separate coarse silicate particles (clasts) from fine calcrete containing carnotite.

The calcrete fines will be leached to produce a pregnant leach solution (PLS), which will be concentrated using nanofiltration membranes that will enable a clean separation of uranium and carbonate from water to produce a low permeate carbonate and uranium.

The PLS concentrate will undergo vanadium precipitation to produce vanadium and sodium diuranate precipitation to produce uranium. The uranium barrel liquor will be treated and sent to the tailings disposal.

The Tumas process is designed to yield a tailing slurry with minimal levels of valuable components, including uranium, vanadium, and carbonate. It not only offers economic and environmental advantages but also results in a tailings stream that is considered environmentally safe due to its low radioactive content.

Site infrastructure

The project site is accessible by the C28 national highway, which stretches from Swakopmund to Windhoek. A newly constructed 13.5km access road links up with the C28 approximately 60km away from Swakopmund.

The power required for the project will be provided by the Namibian regional grid via a dedicated 45.1km, 132kV power line originating from the Kuiseb substation near Walvis Bay. The power voltage will be stepped down to 11kV at the Tumas substation. A 20MW on-site solar farm is also proposed to be installed. A 2.5MVA diesel generator will be installed for emergency backup power.

Freshwater will be sourced from the Swakopmund reservoir, managed by Namibia Water (NamWater). It will be delivered through a 65km pipeline that runs parallel to the C28 highway, with a capacity of 2.4 gigalitres a year.

Permanent accommodation is not allowed within the NNNP, due to which all permanent employees will live either in Walvis Bay, Swakopmund, or nearby camps. The employees will be transported to the site by bus.

Contractors involved

Australia-based services provider Ausenco has prepared the feasibility study for the project. It has also contributed to capital cost estimation for processing plants and engineering designs.

Namisun, a Namibia-based independent environmental consultancy company, oversaw the environmental impact assessment (EIA) process and environmental clearance applications for the Tumas project. They were also responsible for creating the environmental management plan (EMP) for the project.

Cube Consulting, a consulting specialist in the mining industry, was responsible for the ore reserve estimates and mining engineering design.

Gill Lane Consultancy and Nuclear Fuel Associates have also contributed to the mineral resource and uranium marketing.