The Tshipi Borwa Manganese Project is located 20km south-west of Hotazel at the Kalahari Manganese Field (KMF) in South Africa. It is one of the largest open pit mining projects in the KMF basin, which covers a 400m² area. The mine is owned and operated by Jupiter Mines and Ntsimbintle Mining.

Jupiter Mines acquired its 49.9% stake in the mine in November 2010 at a cost of A$245m. Ntsimbintle Mining holds the remaining 50.1% interest in the mine.

Turgis Consulting completed the feasibility study of the mine’s development in May 2010. The development was approved in February 2011 by Tshipi Board. Construction will begin in 2011. The mine and the processing plant will be successfully commissioned in 2012.

Project finance

In order to build the Tshipi Borwa Mine, Jupiter Mines raised A$100m (approximately $99m) in January 2011, by issuing 142.9 million shares at a price of A$0.70 per share to institutional investors.

The company has also issued 71.5 million shares to Pallinghurst co-investors at the same price to raise equity for financing its wholly owned Mt Ida magnetite project and Mt Mason direct shipping ore project in the Central Yilgarn region.

Geology and reserves

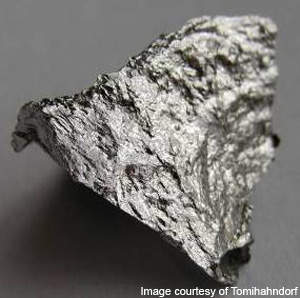

Located in the KMF basin, the Kalahari project comprises Ongeluk formations formed due to the lavas of sedimentary rocks. The Ongeluk formation is a 140m-thick Hotazel formation which constitutes banded iron formations (BIF) mixed with manganese (Mn) lutites.

The Tshipi mine is estimated to contain 163.2Mt of manganese resource graded at 37.9% Mn. The Inferred reserves are estimated to be 101.4Mt graded at 37.1% Mn. The measured and indicated reserves are estimated at approximately 61.8Mt graded at 37.1% Mn. In February 2011, the reserves estimate was revised upwards by 145Mt graded at 31.75% Mn.

Mineralisation

The mineralisation consists of lighter BIF deposits which comprise high grade manganese ore and low grade silica, alumina, phosphorous and other deleterious elements. The Hotazel formation comprises Fe and Mn deposits lying from 50 to 80 west.

The lower section of the Hotazel formation constitutes three manganese rich zones, the upper manganese ore body (UMO), middle manganese ore body (MMO) and lower manganese ore body (LMO).

The UMO is 10cm to 15cm-thick and comprises moderate deposits of manganese. The poorly mineralised MMO is 2m-thick and not economically efficient. The LMO is a highly mineralised unit consisting of six important mineralised zones.

Production

The mine is designed for a production capacity ranging between 2.2Mtpa and 2.6Mtpa of run of mine (ROM) manganese ore, with an operational lifespan of 26 years. It is expected to produce 2.4Mpta of directly shippable Mn ore by mid-2012.

Mining and processing

The mine will consist of office buildings, processing plant and a tailing dam. The manganese ore deposits will be extracted using conventional open-pit excavation methods encompassing drilling, exploring, blasting, loading and hauling.

The BIF and Mn will be extracted from the mine and transmitted to the plant for further processing. The plant will execute crushing, screening, conveying and stockpiling operations to produce carbonaceous directly transportable ore product.

The plant will break down the BIF contaminants into minor particles and produce high grade Mn concentrates through a gravity separation system. These concentrates are suitable for producing robust steel.

Transport and handling

Tshipi is planning to build its own 4km-long rail loading facility which will connect to the existing Transnet for transporting the manganese deposits extracted from the open-pit mine. Transnet transports 4.4Mtpa of rail and port capacity by connecting KMF to the Port of Elizabeth.

Despite having road, power, rail infrastructure and water supplies, Hotazel cannot meet the requirements of the Tshipi mine due to insufficient transmission and distribution infrastructure. The power will be supplied to the mine through diesel driven generator units until the state owned electricity provider Eskom will provide power from its grid network.