The Troilus gold-copper project is an open-pit mine being developed in Quebec, Canada, by Troilus Gold, a Canadian mining company.

The project is being realised in the old Troilus mine, which was operated by Inmet Mining between 1996 to 2010. The mine was acquired in 2017, and a feasibility study to reopen mining operations at the site was completed in May 2024.

The Troilus mine is estimated to have a life of mine (LOM) of 22 years with an initial investment capital of approximately $1.07bn.

The project is estimated to have an annual production capacity of 244,600oz of gold, 17.3 million pounds of copper, and 446,700oz of silver over its operational period.

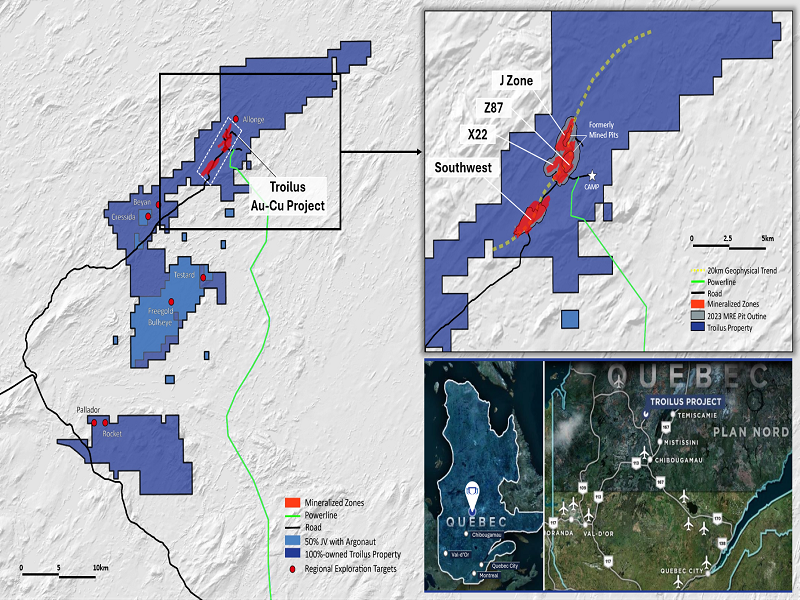

Troilus Gold-Copper Project location

The Troilus gold-copper project is situated approximately 120km north of Chibougamau, in Quebec, Canada. The project is in the tier-one mining jurisdiction of Quebec within a 435km² area of the Frotet-Evans Greenstone Belt.

Geology and mineralisation of the Troilus deposit

The Troilus deposit, part of the Frotet-Troilus domain in northeastern Quebec, is embedded in volcanic and hypabyssal intrusive rocks of the Troilus Group within the highly deformed Parker domain. The property’s geology primarily consists of a thick volcanic sequence with mafic to intermediate compositions.

The mineralisation at Troilus, categorised as Archean porphyry-type deposits, includes gold and copper in disseminated and vein forms, often associated with sulphides. The main host rocks for these mineralised zones are the matrix of the diorite breccia, diorite, and felsic dykes.

Reserves at Troilus project

The proven and probable mineral reserves at the Troilus gold-copper project are estimated at 380 million tonnes grading 0.49g/t gold, 0.058% copper, and 1.00g/t silver, as of October 2023.

The estimated contained metals are 6.02 million ounces (moz) of gold, 484moz of copper, and 12.15moz of silver.

Mining method

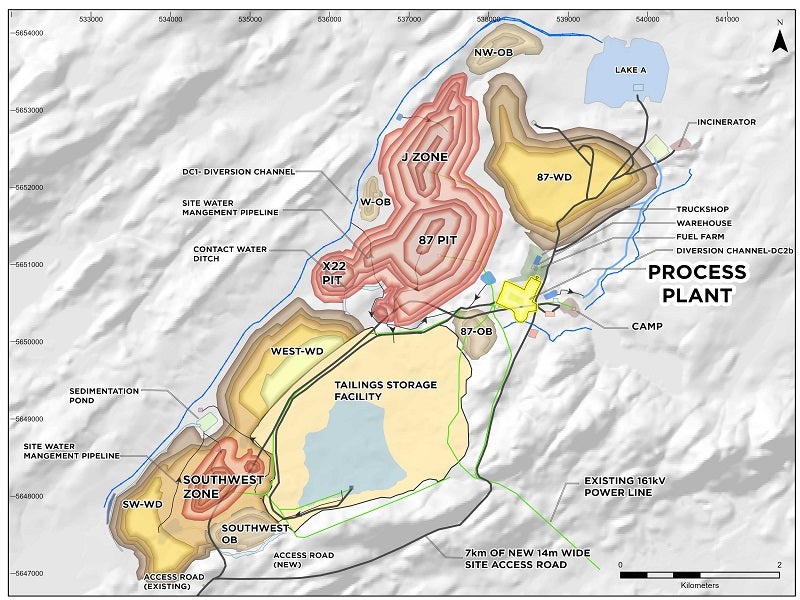

The Troilus gold-copper project is proposed to be developed using conventional open-pit mining methods of drilling, blasting, loading, and hauling. It is proposed to utilise a 100% owner-operated equipment fleet using 227t trucks, electric hydraulic shovels, wheel loaders and drills.

Mining operations will be conducted in four areas, namely Z87, J Zone, Southwest (SW) Zone and X22 at an average strip ratio of 3.1:1. An open pit bench height of 10m will be maintained.

Mining will commence at the Z87 pit area in the pre-production period and continue until year eight. The final phase of Z87 will be mined from year 12 until year 19.

The SW Zone pit area will commence production in year one until completion in year nine. The pit will then be used for the deposition of tailings from year ten to 16.

The J Zone pit area will start production in year five until early year 15. The X22 pit will be mined from years 18 to 21.

Ore processing

The run-of-mine (ROM) ore will undergo crushing in primary and secondary crushers followed by a tertiary high-pressure grinding rolls (HPGR) crusher. The crushed product will pass through a classifying cyclone cluster before grinding.

The crushed product will be mixed with water and lime and fed to a ball mill. The ground product will be conditioned before undergoing flotation. The flotation tailings will be thickened and pumped to the tailings storage facility.

The flotation concentrate will be fed to a regrind circuit and provision has been made to install gravity gold concentration for the primary and regrind circuit in year one to produce gold doré.

The concentrate will undergo three-stage cleaning with the cleaner flotation circuit, which will also be equipped with two-stage cleaner scavenger columns. The resulting concentrate will be fed to a concentrate thickener which feeds the concentrate filter.

The final copper concentrate, enriched with gold, will be stored in containers and sent to a smelter for refining.

Site infrastructure

The Troilus project benefits from significant existing infrastructure, upgraded from previous operations.

The project site is accessible via an all-weather road from Chibougamau.

Other existing infrastructure at the project site includes a transmission line and a 50MW substation for power, a tailings facility, a water supply and treatment plant, and camp facilities.

Contractors involved

The feasibility study for the project was undertaken by AGP Mining Consultants, a mine engineering company.

Lycopodium Minerals Canada, a subsidiary of engineering and project delivery services provider Lycopodium, was also involved in the feasibility study.