The Slivova gold project, situated in Kosovo, is currently being developed as both an open-pit and underground mine.

The project was originally owned by Innomatik Exploration Kosovo, a subsidiary of Canada’s Avrupa Minerals. It was later acquired by AVU Kosova, a wholly-owned subsidiary of Avrupa.

Western Tethyan Resources (WTR) executed an earn-in agreement with Avrupa in May 2023, with an option to earn-in up to 75% of the project.

The preliminary economic assessment (PEA) for the project was completed in September 2023.

The project is estimated to yield an average annual production of 13,000oz of gold, with a projected mine life extending beyond seven years.

The capital expenditure for the Slivova project is estimated at $33.4m.

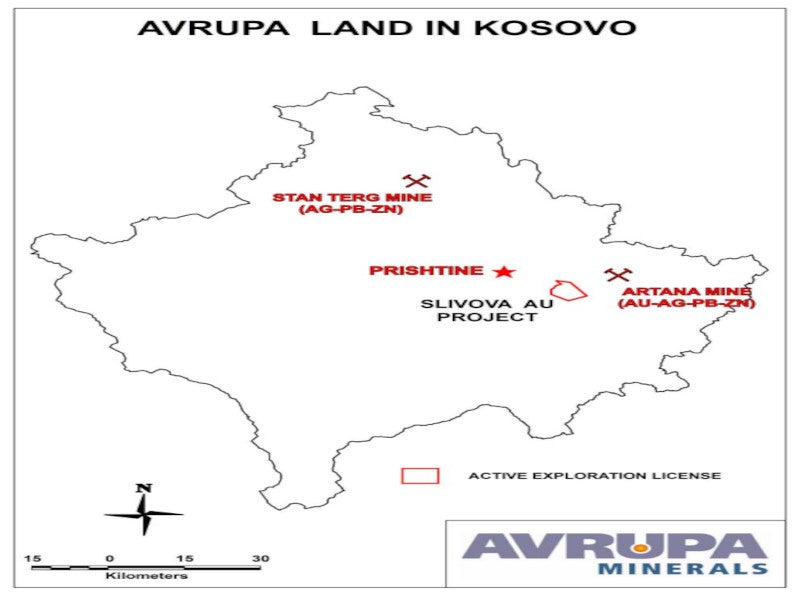

Slivova gold project location

The exploration licence for the Slivova project is located along the Vardar Trend, approximately 30km south-east of Pristina, the capital city of Kosovo.

Geology and mineralisation

The project lies within the Slivova licence area, where two distinct geological units have been identified: the calcareous unit and the non-calcareous greywacke.

The calcareous unit comprises repeating sequences, including calcareous pebble conglomerate, calcareous sandstone, calcareous cobble conglomerate, and grey siltstone.

Conversely, the non-calcareous greywacke unit is characterised by varying thicknesses of non-calcareous sandstone, grey to black siltstone, and greywacke, distinguished by mud rip-up clasts and a faint arkosic texture.

Gold mineralisation in the Main Gossan and Gossan Extension is predominantly found within the calcareous pebble conglomerate and calcareous sandstone.

Slivova gold project reserves

The measured and indicated resources at the Slivova project are estimated at 1.13 million tonnes, grading 4g/t gold and 15g/t silver, as of September 2023.

The total contained gold and silver is estimated at 146,000oz and 546,000oz, respectively.

Open-pit mining

The Slivova project will employ both open-pit and underground mining methods.

The mining plan for Slivova will commence with a small open pit to access the mineralised gossan area, followed by the underground extraction of the gold resource beneath the pit.

The mine design will be refined through detailed analysis and stope optimisation, which allows for flexibility in accommodating varying rock competencies, particularly in contact zones.

The starter pit will be designed for immediate ore extraction, starting from the top bench and progressing downwards, thus eliminating the need for prestripping. Local contractors are expected to undertake the open-pit mining.

The design will aim to minimise environmental impact and avoid the need for stream realignment.

Underground mining

The primary underground access is proposed to be located down the valley at approximately 815m above the maximum residue level, heading north towards the ore body situated at 820 maximum residue level.

The secondary access is planned to be established on the northern side of the valley, slightly below the open-pit access, at the 840 maximum residue level.

The bottom bench will be established at 865 maximum residue level, with access integrated into existing tracks, simplifying the removal of overburden and ore.

Pit operations are anticipated to conclude after the first year.

Underground mining will commence through a portal on the south valley wall, primarily employing sublevel open stoping.

Sublevels will be spaced at 20m intervals, with a 25m crown pillar separating the open-pit bottom, which will later be mined using sublevel caving as the mine approaches the end of its life.

Stoping will be conducted using a bottom-up approach, with stopes above only becoming mineable once the lower stope has been mined and backfilled.

Adjacent stopes on a level will be mined once the adjacent stope has been backfilled or remains in-situ.

Crown pillar stopes will be mined after all standard open stopes are completed, with each crown pillar being mined following the completion of the adjacent stope.

Ore processing at Slivova

Run-of-mine ore will undergo crushing in a jaw crusher, with the crushed material transported via a screen feed conveyor. The crushed ore will be screened, and oversize material will return to the secondary cone crusher.

The undersize material will be conveyed to the ball mill for further grinding. The discharge from the ball mill will be pumped to one of two classifying cyclones.

The overflow from the cyclones will be directed to the leach feed thickener, where it will be thickened to a consistency of 40% solids before being pumped to the leach circuit feed tank.

A proportion of the cyclone underflow will be recirculated to the mill feed, while the remainder will be channelled to the gravity concentrator.

Gold and silver will be extracted, with the tailings being discharged back to the mill feed trunnion. The concentrate from the gravity concentrator will flow to the mill circuit table, resulting in the production of ore concentrate for sale.

The tailings from the table will then be pumped to the leach circuit feed tank for additional processing.

Thickened cyclone overflow and table tailings will be introduced into carbon in leach tank, where the ore will undergo leaching.

The carbon will be leached in a concentrated chloride solution, and the resulting pregnant leach solution will be directed to the electrowinning cells, where gold will be deposited onto cathodes.

The loaded carbon will be stripped and smelted in an electric arc furnace to produce gold-silver bullion.

Site infrastructure

The site is accessible by a dirt road from the nearby village of Slivova and via a longer dirt road from the settlement of Peshter.

A separate haul road will be constructed to connect the main portal to the processing plant, which is situated on an adjacent hilltop.

Power will be supplied via a 33kV overhead powerline, which is part of Kosovo’s national grid and runs parallel to the M25 road.

Contractors involved

Bara Consulting, an engineering consultancy, was engaged by WTR to prepare the PEA for the Slivova gold project.