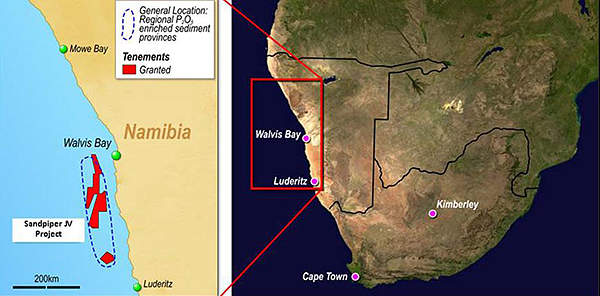

The Sandpiper Marine Phosphate Project is located in the Namibian waters of the South Atlantic Ocean. The deposit is situated 120km off Walvis Bay in the Namibian continental shelf. The water depth in the area varies from 180m to 300m. The licence area is 25.2km wide and 115km long, covering roughly 2,233 square kilometres.

The project is owned by Namibian Marine Phosphate (NMP), a joint venture between Namibia-based companies Minemakers (42.5%), UCL Resources (42.5%) and Tungeni Investments (15%).

The marine deposit was discovered by Gencor, a South African mining company, in the 1990s. It is believed to be the largest identified marine phosphate deposit in the world. Its development was considered to be sub-economic at prices that prevailed at that time. With the rapid increase of phosphate (P2O5) concentrate prices over time, the project’s economic feasibility is being reviewed.

The definitive feasibility study of the project was completed in April 2012 by lead consultant Bateman Advanced Technologies, in association with Jan de Nul, Paterson & Cooke Consulting Engineers, Lithon Project Consultants and Enviro Dynamics. Bateman will also provide the basic engineering and front-end engineering design for the processing plant.

Production from the deposit is expected to begin in the fourth quarter of 2013. It has an expected mine life of 20 years.

Geology, reserves and mineralisation at the Namibian marine deposit

The phosphate containing area at the Sandpiper deposit overlies a Miocene footwall clay layer. The phosphates are understood to be formed due to chemical precipitation and digenetic concretionary growth in unconsolidated sediment.

The deposit is estimated to contain measured and indicated resources of 4.09 million tons (mt) and 220.3mt respectively, at a cut off grade of 15%. Inferred resources are estimated at 1,607.8mt.

Phosphates at the deposit occur in the form of ooliths and pellets, containing sediments with calcium carbonate and phosphate. Associated minerals include quartz, ilmenite and sulphides.

Mineralisation occurs principally in two layers. The upper layer is shell-like and of a lower grade, compared to the layer below it. The top layer is of Miocene age, with thickness varying from 0.1m to one metre. The lower layer overlies an alternating sequence of phosphate and footwall clay layers.

Mining of the Sandpiper marine phosphate project

The Sandpiper phosphate deposit is planned to be developed using trailing suction hopper dredging (TSHD) technology. A TSH dredger vessel consists of a retractable dredge arm and a suction dredge head to extract marine sediments from the sea bed.

Extracted sediments are transferred to an integrated hopper of the vessel, then pumped to shore. NMP plans to use the MV Cristobal Colon vessel for dredging. The dredging services will be provided by Belgian company Jan De Nul.

Bulk sampling for the feasibility study was conducted using a two cubic metre mechanical grab and recovery system aboard the offshore vessel MV Smit Madura.

The project will initially produce rock phosphate for marketing in Africa and other countries. Phosphate sediments of approximately five million tons per annum will be recovered initially by dredging.

The dredging will be initially carried out at water depths up to 225m and later extended to 275m.

Processing of phosphates at a pilot beneficiation plant in South Africa

A pilot beneficiation plant with production capacity of about 125t of phosphate rock concentrate has been built in Johannesburg at Mintek’s facility. It will be converted to a full scale commercial facility depending on its feasibility.

The run-of-mine ore from the bulk samples collected is fed to the pilot plant. The processing begins with screening of material to 1mm size. Coarse material of more than 1mm size will be separated by the screeners.

The less-than-1mm size material is passed through hydrocyclones to remove material of less than 100 micron size. Resultant material is fed to a spiral gravity separator which separates fine shell from phosphates.

The concentrate’s grade and quality are improved through attrition. The resultant material is washed to remove any chlorides and dried.

Transportation and handling of ore and processed phosphates

The recovered sedimentary phosphate material will be transported by the dredger vessel and pumped to shore. It will be transferred in the form of slurry to a buffer pond onshore through a pipeline. The screened slurry will be pumped to the processing plant through another pipeline.

Processed phosphate from the plant will be transported to end user markets from the port of Walvis Bay.

Environmental impact of the South Atlantic Ocean-based Sandpiper deposit

The draft environmental impact assessment and environmental management plan were submitted to the Namibian Ministry of Environment in January 2012. The reports were prepared by J Midgley and Associates and Enviro Dynamics. No significant impact of the project has been identified on the surrounding marine environment.

A separate environmental impact assessment is being prepared for onshore activities of the project.

Future developments for Namibian Marine Phosphate’s (NMP) deposit

NMP plans to expand operations of the Sandpiper marine phosphate project to include a beneficiation and chemical processing plant, to produce finer phosphate products for use in fertiliser production.