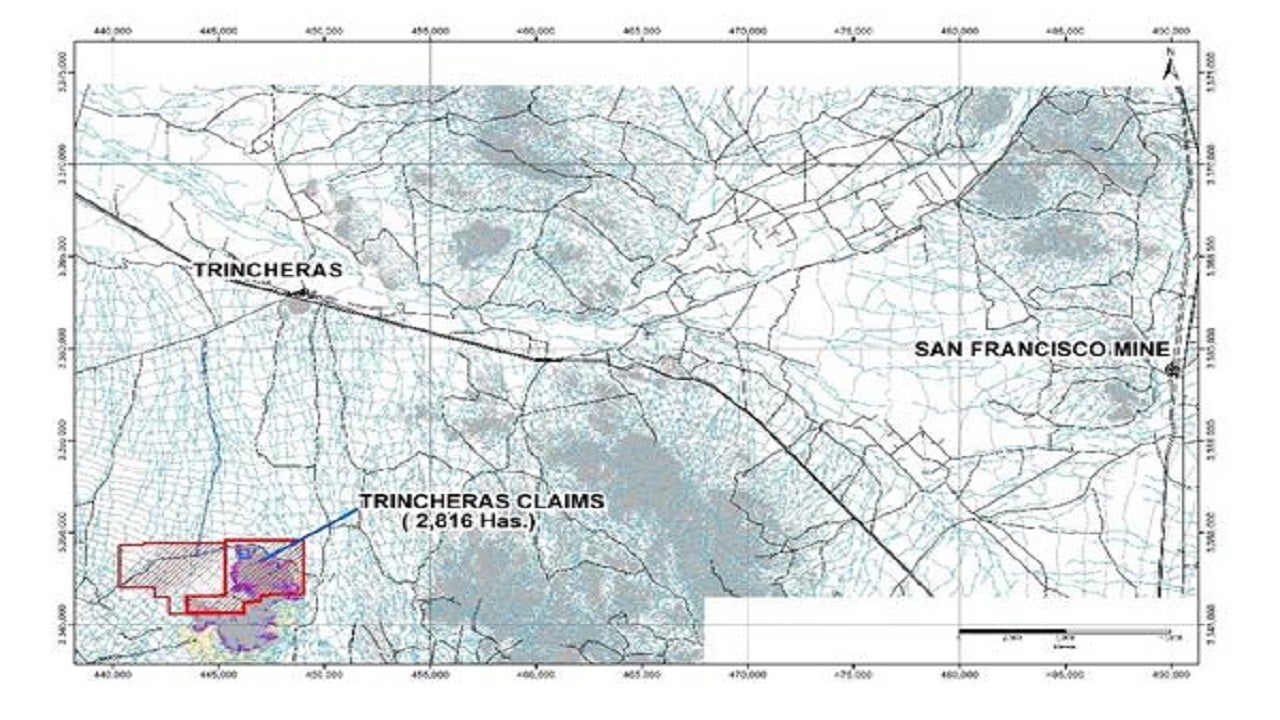

The San Francisco mine is a gold and silver mine in Sonora, Mexico. It is located in Santa Ana, in the north-central part of Sonora, approximately 150km north of Hermosillo.

The property comprises 21 contiguous mining concessions spanning an area of 47,395ha.

The mine is 100%-owned by Magna Gold, which acquired the mine from Timmins, a wholly owned subsidiary of Alio Gold, in May 2020 under an agreement signed in March 2020.

It started operations in 2010 and produced more than 820,000oz of gold until production was ceased in 2018 as leach pads reached a residual leach cycle. The results of the pre-feasibility study on the mine were announced in September 2020. Mining and processing operations resumed during the third quarter of 2020.

San Francisco gold mine reserves

The San Francisco gold mine is estimated to contain 46.8 million tonnes (Mt) of proven and probable reserves graded at 0.499g/t, with contained gold of 752,000oz, as of August 2020.

Mining at San Francisco gold mine

The San Francisco project includes two previously mined open-pits, namely, San Francisco and La Chicharra pits, along with heap leach processing facilities and associated infrastructure located near the San Francisco pit. Both the pits employ open pit mining methods.

Magna will exploit a small underground mine at the San Francisco pit, targeting higher-grade mineralisation in the block model.

The reserves, primarily from open-pit, will be mined and heap leached over an initial mine life of eight years. The gold mine is currently processing minerals from the La Chicharra pit, along with stockpiled material, with plans to resume open-pit mining in the San Francisco pit. In addition, underground mining will be undertaken in the south wall of the San Francisco pit.

The pit designs were revised following Magna’s takeover of the mine and the current mine plan also includes the reserves for the La Chicharra pit. The new design includes four mining phases designated as six, seven, eight and nine, with seven sub-phases.

The current mine plan envisages mining of high-grade ore lenses using an underground cut and fill mining method, contrary to the earlier suggested method of mining via an open-pit pushback of the pit. The rest of the ore in the pushback will be mined as part of one of the sub-phases of the mine production plan at the San Francisco pit.

Processing details

The processing plant includes multi-stage crushing and screening, followed by conveying and stacking of crushed ore onto a heap leach pad. The subsequent processing stages include cyanide heap leaching, followed by the recovery of gold from the pregnant solution, Zadra-type elution, electrowinning, and smelting.

The mined ore undergoes crushing via two crushing and screening circuits. The first crushing circuit operates at 15,000 tonnes a day (t/d), while the second, newer circuit can process 7,000t/d, for a total crushing capacity of 22,000t/d.

The product from the crushing plants is sent to the leach pad via overland conveyors and collected on the pad with a stacker.

The pregnant leach solution is pumped from the pregnant solution storage pond to two adsorption-desorption-recovery (ADR) plants. The first adsorption plant has carbon columns arranged in two parallel lines. Each column consists of five tanks in a series, through which the carbon advances to the solution flow.

The second ADR plant, comprising a new line of carbon columns with five tanks each, was installed in 2011. It was followed by the addition of a new stripping circuit in 2017.

Infrastructure at San Francisco gold mine

The building at the mine site provides space for on-site mine administration along with catering and ablution facilities. A vehicle workshop is used for the maintenance of the haul trucks, excavators and ancillary vehicles. Built in December 2010, a 150m² building accommodates the exploration offices.

A general warehouse accommodating process reagents, while mechanical spares is situated north of the ADR plant.

The site receives power from Comisión Federal de Electricidad (CFE) via a 33kV overhead line. Power is distributed to the crushing and screening plant and other areas of the site. The new crushing circuit is powered by diesel generators with a capacity of approximately 2MW.

Contractors involved

Peal Mexico was hired by both Alio and Magna to perform mining activities at the site. The Mexican Geological Service was contracted by Alio to perform geological survey over the site.

Micon International was engaged by Magna to prepare of the independent technical report for the project.