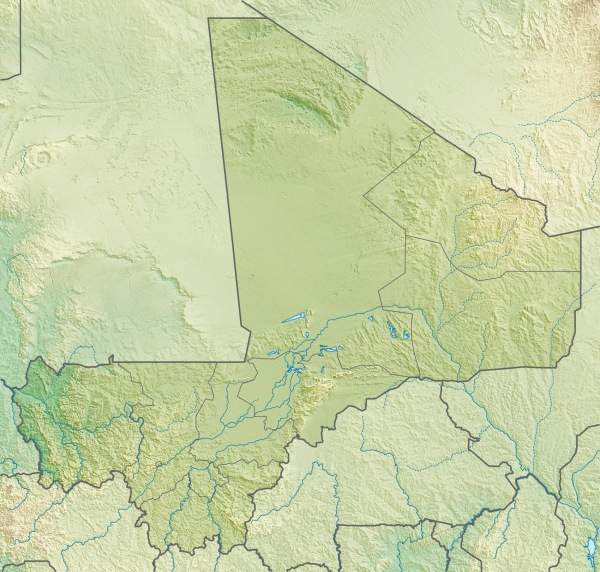

The Sadiola Mine is an open pit gold mine which has been operating since 1996 in Kayes, the capital region of Mali. The deposit is situated in the remote parts of Mali and is spread over an area of 302km² with limited infrastructure.

It is 82% owned by the joint venture of IAMGOLD and AngloGold Ashanti and 18% by the Mali Government. It is being operated by AngloGold Ashanti.

The mining operations comprise the Sadiola main pit and four satellite pits. The plant was originally designed to process soft oxide ore but was eventually modified to treat hard oxides as well.

Mining at the main pit now stands complete with operations being carried in the third and fourth satellite pits situated southeast of the main pit.

Expansion of the Mali-based gold mine

Operating for more than 15 years, the mine is scheduled to close between 2013 and 2015. However, a pre-feasibility study completed in 2009 to mine deep ore sulphides is expected to extend the mine-life by an additional six years until 2019.

Known as the deep sulphides project (DSP), it is the down deep extension of the Sadiola main pit. Based on the positive pre-feasibility studies, AngloGold Ashanti approved a $9m feasibility study (FS) of the DSP in November 2009.

The study was completed in November 2010. Environmental impact assessment (EIA) is currently underway and the preliminary drilling targets identified to commence drilling in 2012.

If approved, the project will increase production levels from 350,000oz/year, as in 2009, to between 400,000-500,000oz/y from 2013 through to 2018 resulting in the total production increase of the mine to about 2.2 million oz in its current mine life.

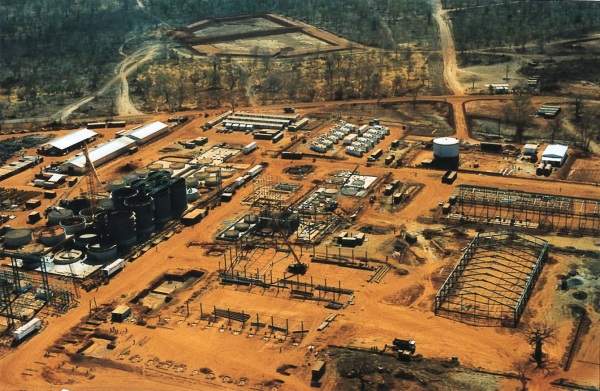

The project will also witness construction of a new crushing, grinding and carbon-in-leach (CIL) plant to process combined feed of 8.5 million tons (mt) of ore a year. The combined feed includes the existing hard ore stockpiles and the deep sulphides.

Geology and reserves of the Sadiola Mine

The Sadiola Gold Mine is located in the north central section of the Kenieba-Kedougou window. It is hosted in the Kofi formation, consisting of fine greywacke and impure carbonates with minor tuffs and acid volcanics.

The Kofi Formation is separated by the volcano-sedimentary zone situated in the west of the Kenieba-Kedougou window.

The volcano-sedimentary zone is intruded by calc-alkaline batholiths belonging to the Saboussire formation.

The Sadiola deposit originally consisted of an upper oxidised cap and an underlying sulphide zone. Shallow saprolite oxide formed the primary source between 1996 and 2002, after which mining of deeper saprolitic sulphide commenced.

As of December 2010, the total measured stockpile was 9.6mt, graded at 1.39g/t, and the DSP indicated and inferred sulphides accounted for 41.2mt and 13.27mt, graded at 1.77g/t and 1.6g/t respectively.

Mineralisation in the capital region of Kayes

Gold mineral exists in marble, greywacke, diorite and quartz-feldspar porphyry associated with a complex alteration pattern that includes calcsilicate, potassic, chlorite-calcite and carbonate.

Gold is present in accumulations such as arsenopyrite, pyrrhotite, pyrite, stibnite and gudmundite that are dominated by arsenic and antimony sulphides.

Gold grades in the range of 2g/t to 20g/t are present in the striking Sadiola Fracture Zone (SFZ) with 020º striking splays in steep to vertical plunges.

The SFZ is deep and meets the greywacke in the west and impure carbonate in the east. A discontinuous granular and intrusive rock (diorite dykes) consisting of weak mineral layers and intense pliable deformation intrudes the SFZ and its wall rock.

Processing gold from the open pit Sadiola Mine

Ore stockpile is located one kilometre way from the pit and is situated between the pit and the processing plant. About 90% of the extracted ore is stockpiled before processing.

The Sadiola processing plant consists of twin circuits designed to treat 5.3mtpa of saprolite ore. The crushed ore from the SAG mill is carried to the leach circuit for leaching.

The pulp is fed into the CIL plant where the carbon is stripped of the associated gold. The gold bearing solution is sent to the storage tanks. Gold is recovered from the solution through electrolysis.

The slurry remaining after the removal of gold is pumped to the tailings dam situated 3km away from the process plant for disposal.