The Razorback iron project is an open-pit iron concentrate mine proposed to be developed by iron ore mining company Magnetite Mines in South Australia.

A pre-feasibility study released in 2013 indicated that the mine will have an estimated production of four million tonnes per annum (Mtpa) to 9Mtpa of concentrate. The project development was affected by a decline in iron ore prices, resulting in a slowdown in development activities in 2013. A scoping study completed in 2019 provided positive results.

Announced in July 2021, a pre-feasibility study on the Razorback iron project envisaged a net present value (NPV) of A$296m ($222.61m) and a life of mine (LOM) of 37 years.

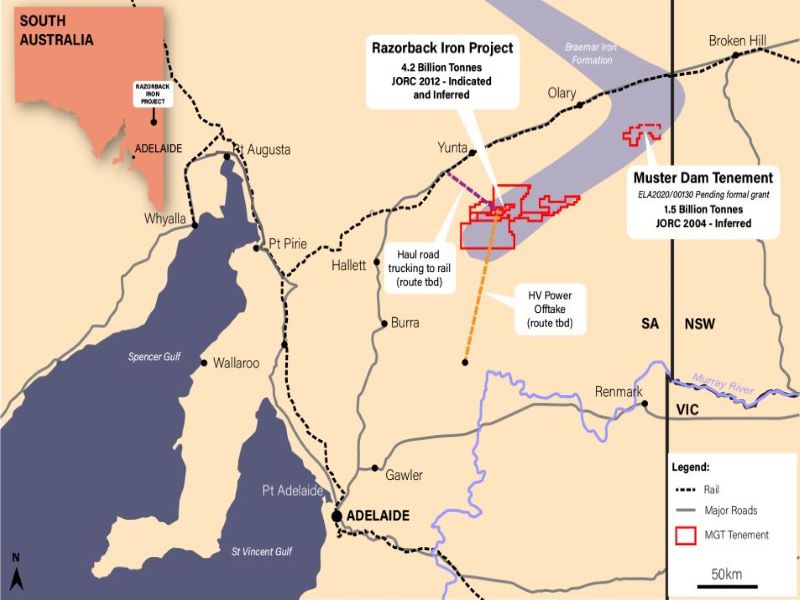

Razorback iron project location and geology

The Razorback project is located in South Australia, approximately 40km south of Yunta and the Barrier Highway. It encompasses five exploration licences spanning approximately 1,520km² within the Braemar Iron Formation in South Australia.

The iron ore mining project lies within the Adelaide Geosyncline, a linear tectonic rift basin trending north-south to north-east and comprising late Proterozoic and early Cambrian era sediments. The magnetite deposit at the project site is hosted by the Neoproterozoic glaciogenic meta-sediment of the Braemar Iron Formation.

Razorback iron project mineralisation and reserves

The mineralisation within the Braemar Iron Formation occurs in a simple dipping tabular body featuring minor faulting, folding and intrusives with typically fine-grained ironstones. It is present as magnetite, quartz, and hematite, with lesser amounts of sericite, apatite, dolomite, feldspar, and chlorite. The non-ferruginous bands comprise biotite, dolomite, quartz, sericite, plagioclase, and chlorite, with traces of hematite and magnetite.

The probable mineral reserves at the Razorback iron project were estimated at 472.7Mt, as of May 2021.

Mining methods at Razorback iron ore project

The magnetite project will utilise traditional open-pit mining methods involving drill, blast, load, and haul operations. The proposed mining fleet includes a 350t excavator as a primary unit with front end loader (FEL) backup for loading medium-class rear dump trucks with load capacities of 150t to 190t.

The life of mine (LOM) stripping ratio is planned at 1:0.16, starting with a ratio of 1:0.20 in the first five years of production. The pit walls will be angled at 75° with a berm width of 8.5m and a bench height of 20m. The blasting height will be 10m while the mining benches will be excavated at 2m x 5m flitches to improve ore selectivity.

Ore processing at Razorback project

The run of mine (ROM) ore will undergo crushing in a primary gyratory crusher followed by secondary cone crushers. It will undergo grinding in two high-pressure grinding rolls (HPGRs) operating in series, followed by magnetic separation in a primary magnetic separation circuit, including a single-stage counter-rotation low-intensity magnetic separator (LIMS). Secondary grinding will be conducted in a ball mill and the ore will be passed on to the secondary magnetic separation stage.

The concentrate from the secondary magnetic separation will be transferred to the rougher flotation circuit to remove non-ferrous materials, particularly silica. The iron-rich flotation tailings will be sent to the concentrate thickener while the silica-rich flotation concentrate will report to the fine grinding mill, which is envisaged to be a high-intensity grinding mill (HIGmill) or IsaMill operating in an open circuit. The mill will utilise a stirred milling method that focuses on particle-on-particle abrasion and attrition forces for size reduction.

The finely ground product slurry will be processed through cleaner magnetic separators to produce the magnetite concentrate. The proposed processing method has an estimated recovery rate of 16% based on a plant throughput of 12.8Mtpa to produce up to 68.5% iron (Fe) concentrate.

Infrastructure of Razorback iron ore project

The project site will be accessible via a new 44km-long access/haul road from the Barrier Highway.

The electricity required for the project will be drawn via the ElectraNet 132kV supply line from Robertstown Substation, which is approximately 130km away from the site. The transmission line is expected to be connected to a new 132/11kV substation at the project site.

Contractors involved in the iron ore project

Multinational consultancy and engineering firm Hatch provided metallurgical and mineralogical review, and processing plant design, engineering and optimisation. Hatch and Australian geotechnical and water services specialist PSM provided the tailings storage facility design and review services for the pre-feasibility study.

The pit optimisation studies, mine design, scheduling and mining cost modelling were completed by Orelogy Mine Consulting, a consultancy firm based in Australia.

Mining consultancy company McElroy Bryan Geological Services (MBGS) was selected to perform geological and geophysical studies and reviews.