Pike River Mine is the second largest hard coking coal export mine in New Zealand.

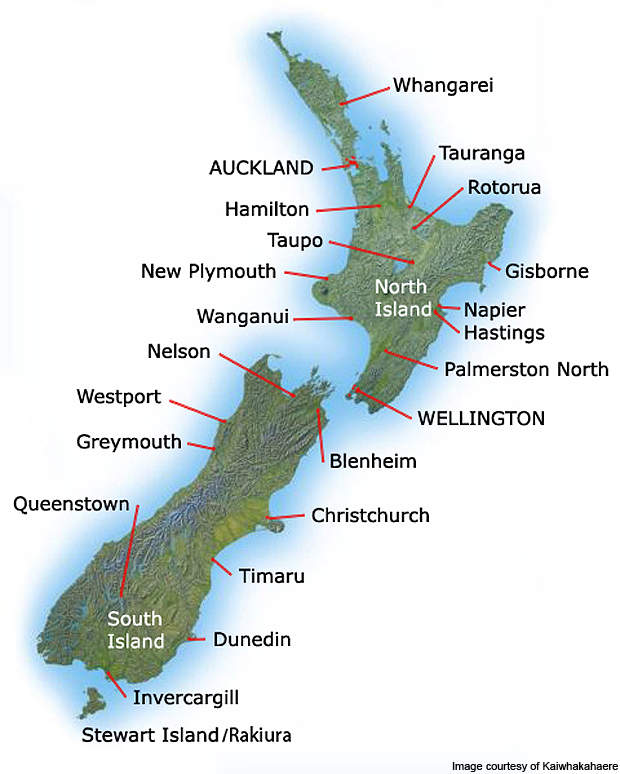

It is located about 50km north-east of Greymouth in the west coast region of South Island. The mine is owned by Pike River Coal, the only listed coal mining and export company in New Zealand. The company is owned by New Zealand Oil & Gas (29%), Gujarat NRE Coke (7.14%) and Saurashtra Fuels (5.5%) and the remaining by public stakeholders.

The mining on Pike River Coal reserves was started in October 2008 by digging a 2.3km access tunnel under the Ranges for two years. The reserves lying in the Brunner coal seam are the largest of their kind in the country.

The necessary mining permit was obtained after 10 years of the initial pre-feasibility study. The company extensively consulted with the authorities concerned, local communities and the Department of Conservation (DOC) for seven years.

A series of four blasts occurred at the mine in November 2010. The 29 miners and contractors trapped in the mine are feared to have been killed after the second blast.

The blasts are suspected to have been caused due to toxic gases.

As of early December, efforts are being made to put out the fire by injecting gas into the mine. The New Zealand Government has announced a Royal Commission of Inquiry into the accident.

Geology and reserves

The coal reserves lie under a remote mountain of the rugged Paparoa Ranges. The mine site lies in a largely undisturbed environment. Pike River will restore the site to its natural state after the completion of the mine’s life.

The Brunner coal deposit seam runs 6.5km north-south (length), 1.5km east-west (width) and has a thickness of about 7m. The Brunner seam has estimated in-ground reserves of 58.5mt. The estimated recovery from the seam is 18mt over its 18-year mine life.

Paparoa seams lie about 200m beneath the Brunner seam. Initial drilling estimated an additional potential recovery of 8mt from this seam.

Mining

The Pike River Coal company mines coal from about 150m below the surface of the mountain. Construction of workshops, administration offices and power were completed at the mine site in August 2007.

In October 2008 the access tunnel was dug under the Paparoa Ranges to reach the Brunner seam. This was done to reduce environmental impact on the surface. An eastern pit bottom area was also developed.

The Pike River uses two mining methods which include creating roadways in the Brunner seam through large cutting machines and using hydraulic monitors to break the coal face. The mining was initially done using a NZ$5m road-header machine with tungsten tipped blades.

The water cannons use high pressure blasting with water to break coal at a rate of 2,000t/day. The crushed coal is then washed downhill through a 10km-long, low pressure, slurry pipeline to a processing plant.

The water-fed coal slurry is partly supported by pump and partly by gravity. Usage of a water slurry pipe eliminates the necessity for heavy trucks or surface conveyor belts and this has environmental benefits. The parallel water pipeline passing on the access road was completed in February 2009.

Processing

A NZ$20m coal preparation plant was constructed in January 2009. It was built by a joint venture of Brightwater Engineering and Peat called Brightwater-PEAT. The technologically advanced plant can process 1.5mt of raw coal annually.

About 14,000m³ of water is used a day to transfer coal from the pit face to the processing plant by the slurry pipeline. The processing plant returns clarified water to the mine in a continuous recycling process. The coal is separated from rocks and debris, cleaned and graded.

Four 16,5000t stockpiles are created using a conveyor system and a uniform 35mm size coal is produced by crushing. It is then trucked to the rail loadout facility in Ikamatua.

Pike River has one of the lowest ash content cokes in the world at 1% and has very high fluidity. It has lesser wastes and uses less energy in the coking process.

Production

Production of the hard coking coal from the Pike River mine started in mid-2009. It is exported to international steel mills and coking plants including India and Japan. Coke is the main ingredient in the steel manufacturing process.

In February 2010 the first export shipment of 20,000t was made to India. Production is expected to reach 1m tons a year in 2011.

Transport and handling

A 10km access road to the mine site was constructed in August 2006. In June 2008 TNL Group was contracted for trucking the hard coking coal processed at the Pike River coal preparation plant to the rail loadout facility at Ikamatua.

Constructed in January 2009, the $10m rail loadout facility is located 22km from the coal preparation plant. The loadout centre includes a coal conveyor and a rail loop built by OnTrack. The centre can handle 45 wagon trains.

In November 2007, Pike River contracted Solid Energy, a state-owned-enterprise, for railing coal from the rail loadout facility to the export Port of Lyttelton. The port is located at about 250km from the loadout facility. Both the companies have been contracted to handle 1.3mt of coal a year for 18 years, the expected minimum life of the Brunner seam.