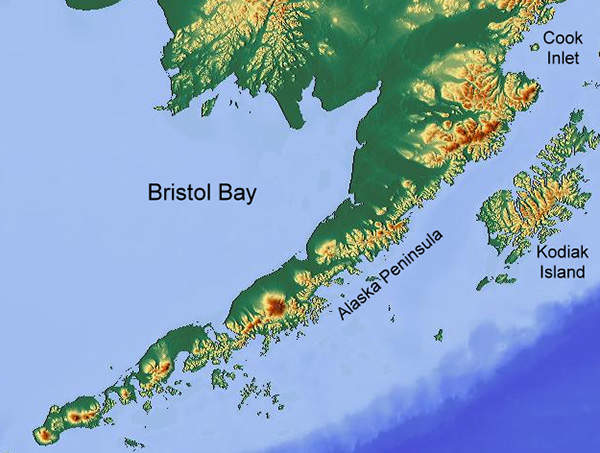

The Pebble Project is located in the Bristol Bay Region in south-west Alaska, approximately 200 miles from Anchorage. It is a green field project based on a copper-gold-molybdenum porphyry deposit, which is considered to be the largest deposit of its kind in the world.

The pebble deposit covers a large area on the state-owned land designated as a potential site for mineral exploration and development. The project was being developed by the Pebble Partnership (PLP), a 50:50 partnership between Anglo American and Northern Dynasty Minerals. Anglo American, however, withdrew from the partnership in September 2013 leaving Northern Dynasty as the sole owner of the project. Anglo American intended to focus on short-term projects and hence expressed its desire to withdraw from the partnership.

The life of the proposed Pebble mine is extendable beyond a century over a number of development stages.

Pebble Partnership invested $556m on the project by September 2013. The project is currently in early stage of development with the pre-feasibility study yet to be completed.

The project needs more than 65 different permits and approvals by several government agencies. Construction will start after the final Environmental Impact Statement (EIS) of the project is published. Northern Dynasty expects to receive environmental approvals in 2014.

Environmental concerns regarding the Pebble Project

A draft watershed assessment of the Bay Area released in May 2012 by the US Environmental Protection Agency raised significant environmental concerns, which has led to concerns over the Pebble Partnership.

An independent consultation process led by Keystone Center was started in October 2012 to discuss the Pebble Environmental Baseline Document (EBD) at length and to receive public input.

The proposed Pebble mine has the potential to produce about one third of the United States’ annual copper needs for many years. However, uncertainty hovers around the project as the US Environmental Protection Agency (EPA) has advised that the project be scrapped, citing its predicted environmental impact.

Pebble has also witnessed significant opposition from local native groups and fishing organisations. The main controversy over the mine’s development is that the project will endanger salmon and other fisheries in the Bristol Bay region.

Pebble Project development history

The western section of Pebble deposit was explored between 1988 and 1997 by Cominco (now Teck), which initially held the mineral rights at Pebble. Northern Dynasty acquired the Pebble deposit between 2001 and 2005.

The known mineral resource at Pebble was extended from one billion tonnes in 2001 to four billion tonnes by 2004. Higher grade mineralisation was discovered at Pebble East area in 2005. Preliminary engineering, environmental and technical studies for developing the Pebble Project had already begun by this time.

In July 2007, Northern Dynasty entered into a 50:50 partnership programme with Anglo American to develop the Pebble deposit. As per the agreement, Anglo American was required to fund $1.5bn for the project for securing its interest and the expenditures were to be split 50:50 later. Anglo American funded $41m in the Pebble Project until it withdrew from the partnership in 2013. The project is now 100% owned by Northern Dynasty.

Wardrop completed preliminary technical assessment of the Pebble project in February 2011. It suggested the possibility of three successive stages of mine development at Pebble comprising 25, 45 and 78 years of mining with a processing rate of 200,000 tonnes per day. It also suggested a payback of 6.2 years for an initial capital investment of $4.7bn in the mine project.

Pebble geology and mineralisation

Pebble is a copper-gold-molybdenum porphyry deposit with the ore body extending up to 1,700m deep from the surface. The deposit is located in the sedimentary basin called Kahiltna Terrane and is believed to have formed about 90 million years ago.

Pebble is one of the largest copper discoveries in the world although the ore body contains less than 1% copper by volume. Metallic minerals found at Pebble include pyrite, chalcopyrite, molybdenite and bornite along with certain amounts of covellite, chalcocite, digenite and magnetite.

The minerals of Pebble deposit are found in fine grains sprinkled throughout the rock. Mineralisation at the western section of Pebble is partially exposed at the surface, whereas the Pebble East hosts higher grade mineralisation deeper beneath the surface.

Mineral reserves

The latest resource estimate of Pebble stands at 5.94 billion tonnes (bt) of measured and indicated resources and 4.84bt of inferred resources.

The resource classification comprises of 80.6 billion pounds of copper, 5.6 billion pounds of molybdenum, and 107.4 million ounces (moz) of gold (67moz measured and indicated). The deposit also contains silver, palladium and rhenium.

Mining and processing plan

Conventional open pit mining as well as underground mining methods are being considered for Pebble. Pebble West is expected to employ open pit method, while underground method (block caving) is expected to be employed at Pebble East.

Copper, molybdenum and gold from the milled ore will be separated using reagents. Froth flotation is planned to be used as the main processing method for Pebble ore.

Ore tailings will be piped into two earthquake-proof artificial tailings structures to be built as part of the Pebble project.

Transportation and power infrastructure at Pebble

The transportation plan for Pebble project involves the construction of a port on Iniskin Bay of Cook Inlet from where the mineral concentrates can be shipped to the smelter. The port is planned to be connected with the mine site through two freight corridors 86 miles in length along the north side of Lake Iliamna.

Four pipelines for carrying copper-gold concentrate, reclaim water, natural gas and diesel fuel along the road are also being considered to be built. The slurry will be dewatered at the port and the reclaimed water will be sent back to the mine.

A 400MW natural gas fired power plant is planned to be built at the mine site.