The New Elk Mine is a coking coal mine located in southeast Colorado, US. It is owned by Australian coal tenements developer Allegiance Coal, who restarted operations at the historic mine in May 2021.

Historical operations at the New Elk mine site took place under the name Allen Mine, where production began in 1951 and continued until 1989. Acquired by American coal exploration and development firm Cline Mining in 2008, the mine was reopened in 2010 under the name New Elk Mine.

The mine was closed in July 2012 due to unfavourable coal market conditions as hard coking coal prices fell significantly. Cline filed for bankruptcy protection and the mine was put under care and maintenance until Allegiance Coal acquired it in 2020.

A feasibility study for the New Elk Mine was completed in November 2019, followed by a start-up mine plan study in January 2020, which was revised in April of the same year.

Come production at the first production unit in the New Elk Mine’s Blue Seam began in May 2021. The second production unit is expected to be brought into production in August 2021.

New Elk Mine location and geology

The New Elk Mine is located in Las Animas County in southeast Colorado. The project area is situated near the border of north-east New Mexico, within the Raton Basin which stretches from Colorado to New Mexico.

The New Elk property features minor faulting seam rolls and igneous dike/sill intrusions. The lithological sequences underlying the property are of the Late Cretaceous to Palaeocene age. The structural stratigraphy dips to the northeast at approximately 3°.

New Elk Mine reserves

The proven and probable mineral reserves at the New Elk mine based on the Green, Blue, and Allen coal seams were estimated at 35.2 million tonnes (Mt) and 9.9Mt for total saleable coal reserves of 45.1Mt, as of November 2019.

Mining operations at New Elk mine

The New Elk mining operation uses the place change room and pillar underground mining method. The mine plan was designed with a minimum coal seam height of 4ft.

The portal entries of the Blue seam are already established with main headings advanced more than 150m underground. The Green seam is accessed via the original Allen seam portals with a single super section.

The operation involves two to three shuttle cars that haul coal from a continuous miner to a feeder breaker, which sizes the coal and then feeds it onto a conveyor belt. The coal is then transferred from the conveyor belt to a stockpile before being fed into the coal handling and processing plant (CHPP).

The mine production will be initially 0.4 million tonnes per annum (Mtpa) in the first six months of operations, before increasing to 1.2Mtpa in the second year and further ramping up to peak production of 3.1Mtpa in the eighth year. The production will then average to 2.7Mtpa for 11 years and conclude in year 24.

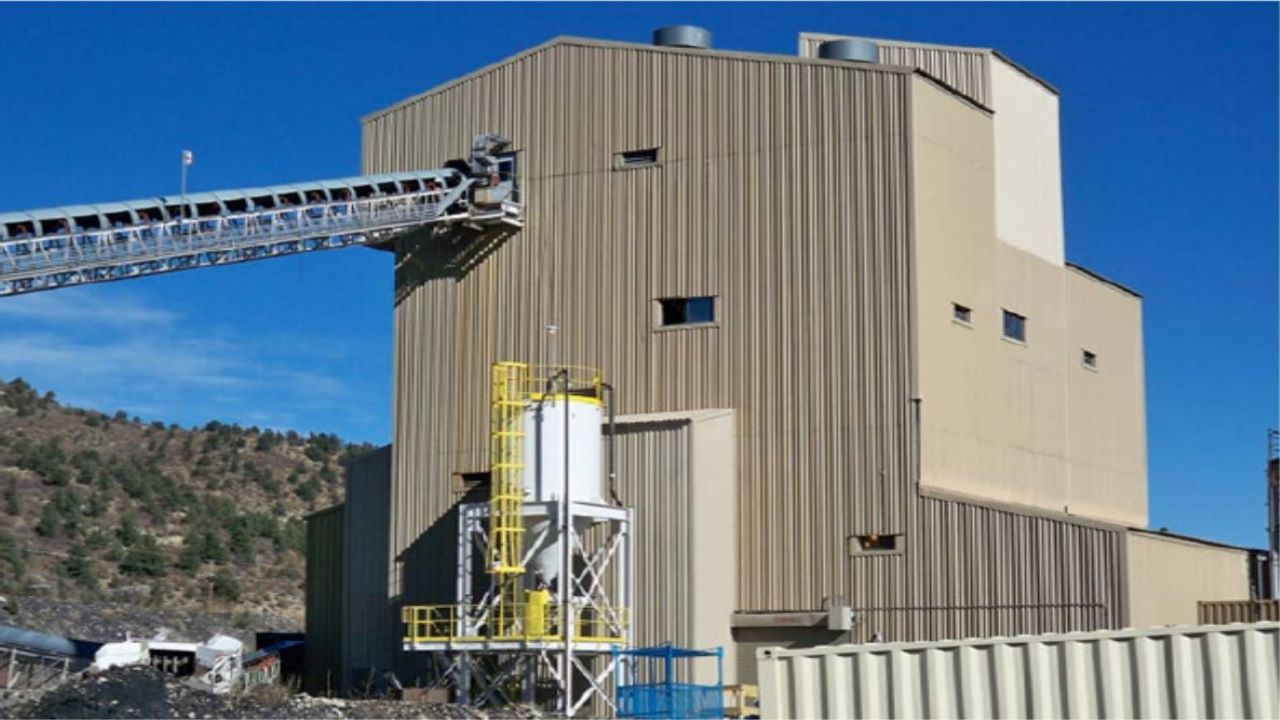

Coal handling and preparation plant (CHPP)

The CHPP has a nameplate feed rate of 727 tonnes per hour (t/h) and the circuit comprises heavy media vessel, spirals, and heavy media cyclones.

The raw coal from the mine undergoes separation via screens into various size fractions and the coarse material is transported to the heavy media vessel to reduce the size. The size fraction down material is then sent to the heavy media cyclone while the remaining raw product is sent to the classifying cyclones, which separate the coal feed to +100 and -100 mesh sizes.

The +100 mesh-sized material is sent to the Spiral Circuit while the -100 mesh material is removed and transferred to the thickener for refuse disposal. The clean coal product exits the CHPP on a single conveyor belt and is deposited onto the clean coal pile.

Coal off-take infrastructure

The coal produced from the mine will be transported from the CHPP to a rail loadout and siding adjacent to a railway track owned by North American railroad company BNSF Rail, in 30t haul trucks in the first two years of operations.

The track will be re-laid during the period from BNSF’s line to the CHPP to load train sets from two 12,500t silos located at the mine site.

The coal will then be railed for 1,368km on BNSF’s line to Pasadena Deepwater Terminal located in the Bay of Houston for export.

Contractors involved in the coking coal project

Canadian design and consulting company Stantec was engaged to undertake the 2019 feasibility study for the New Elk Mine.

Coal trading and consulting company M Resources is the sole marketing and sales agent for the project.