The Mt Carbine is an operational tungsten mine in Queensland, Australia. Fully owned by EQ Resources, the mine is proposed to undergo an expansion.

EQ Resources established a joint venture (JV) with CRONIMET Group, a global commodities trader and metals recycling group, to refurbish, commission, and enhance the tungsten processing plant at the mine in 2019. CRONIMET is also the sole off-taker of the tungsten concentrates produced at Mt Carbine. The plant has been refurbished and expanded to 300,000tpa.

The Mt Carbine expansion project will be implemented in three phases. The first phase will focus on increasing the mine’s productivity through mining and processing of the low-grade stockpile (LGS). Phase two will focus on the commencement of the open-pit mining while phase three will involve a transition to underground mining activities following the depletion of the open-pit resources. A scoping study for the third phase is expected to begin in early 2022.

A bankable feasibility study (BFS) for the expansion project was completed in December 2021. The expansion is estimated to involve an investment of approximately A$21m ($15m) for a life of mine (LOM) of 12 years.

The open-pit mining activities are expected to start in the third quarter (Q3) of 2022. The processing capacity of the plant will be expanded to one million tonnes per annum (Mtpa), with the construction expected to take place in 2022.

Project location and geology of Mt Carbine mine

The Mt Carbine mine is located approximately 130km north of Cairns, Queensland, Australia. The mining area is located within two mining leases (ML), namely ML4867 and ML 4919, which are spread across 366.39ha.

The deposit is situated within the Siluro-Devonian Hodgkinson sedimentary province. The Mareeba Granite and the Mt Alto Granite intrude the north-north-west trending turbidite and siltstones of the Hodgkinson Formation. A stratigraphic component of the Hodgkinson Formation forms an important metabasalt-chert ridge in the western part of the tenement.

Mineralisation and reserves of the tungsten deposit

The tungsten deposit at Mt Carbine comprises several vertical to sub-vertical sheeted quartz veins with widths up to 7m. The tungsten minerals are found within the wolframite and scheelite veins. Tungsten primarily occurs as coarse crystalline varieties of wolframite with varying degrees of volumetrically less significant intergrown scheelite.

The Mt Carbine holds an in-situ open-cut reserve of 1.26Mt, grading 0.71% tungsten trioxide (WO₃) and a historical low-grade stockpile reserve of 10.2Mt grading 0.075% WO₃. The overall in-situ and LGS mineral resource at the mine site is estimated at 21.21Mt.

Mining at Mt Carbine

The Mt Carbine mine expansion will use conventional excavator and truck fleets to extract the in-situ open-cut resource and the historical LGS.

The LGS mining operation will employ a straightforward load and haul process. A 90t excavator will be used on 4m-high benches from top to bottom while a fleet of Bell 50t articulated dump trucks will be used for haulage. The mining operations will commence in the south-eastern section before moving to the north-west.

The in-situ open-cut section will be mined using a standard drill and blast, and load and haul methods. The articulated dump truck fleet will be loaded by a single 100t-120t excavator with a 7.4m³ bucket capacity.

Ore processing at Mt Carbine

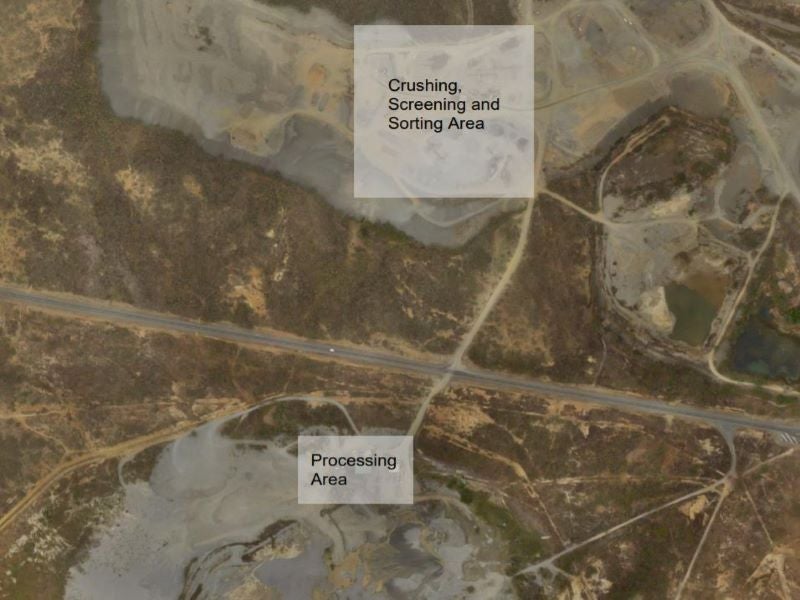

The crushing, screening, and sorting area is located near the LGS while the processing plant is located on the other side of the Mulligan Highway. The plant has a recovery rate of 79.5%.

The crushing, screening and sorting plant for phase one of the expansion programme will be designed to increase the run-of-mine (ROM) throughput to a nominal rate of 170tph of -700mm material.

Improvements to the existing crushing and screening infrastructure of Mt Carbine will include a secondary rolls crusher and the replacement of supervisory control and data acquisition (SCADA). A wet screening stage of -6mm material will be introduced to enhance the efficiency of screening during the wet season. A direct process plant feed of -6mm material will also be implemented to reduce materials rehandling requirements.

Phase two of the expansion will involve the construction of a new crushing, screening, and sorting plant next to the existing plant. The ROM throughput will be increased to a nominal 350tph to establish day-shift-only operations. The crushing and screening circuit will be combined with the ore sorting circuit to reduce material rehandling.

Furthermore, a jaw crusher will be introduced to increase the maximum feed size from 700mm to 1,000mm, along with a scavenging circuit to reduce potential losses from the jig circuit and enhance the plant recovery performance.

Contractors involved in Mt Carbine mine expansion

Australia-based project management and advisory services firm JukesTodd was engaged by EQ Resources to lead the BFS for the Mt Carbine mine expansion project.

Multinational engineering, procurement, and construction management company Ausenco was selected to review and audit the existing processing plant for upgrade options to improve the plant performance for phase one expansion.

Rock Financial Advisory provided a financial model for evaluating the project with operational inputs from mine services firm DAS Mining Solutions (DAS).

Mincore was engaged to provide the estimate for the crushing and screening plant, sorting plant, and tailings dewatering plant.

NRA Environmental Consultants was contracted to supply the estimate for the approvals and rehabilitation while Woodburn Electrical was responsible for the high-voltage power upgrade estimate for the expansion.

Rob Lait & Associates, a consultancy company based in Australia, performed hydrological studies involving sampling and analysis of the groundwater network.

Australian mining services company Measured Group performed the independent re-assessment of the mineral resource.