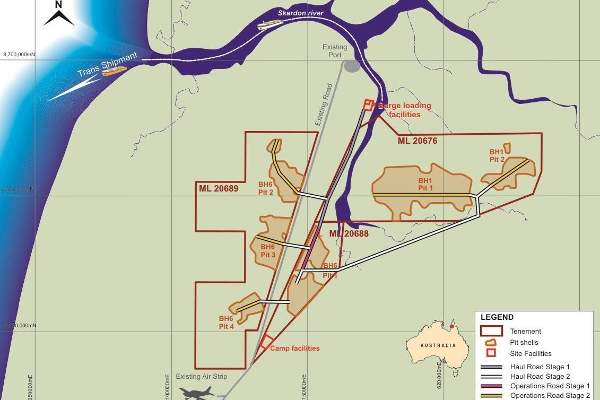

Metro Mining’s Bauxite Hills Project is located 5km south-east of the port at Skardon River and 95km north of Weipa in Western Cape Rock, North Queensland, Australia.

The pre-feasibility study (PFS) for the bauxite project was completed in February 2015, while the definitive feasibility study (DFS) was completed in November. The bankable feasibility study (BFS) was completed in March 2017, and the project received the mining lease from the Queensland government in August 2017.

Construction started in July 2017 and mining operations commenced in April 2018 at an initial rate of two million tonnes per annum (Mtpa). Increased steady-state production of 6Mtpa is anticipated to be achieved over the first four years.

The first shipment comprising 62,000t of bauxite from the mine was made in May 2018 to China’s Xinfa Group.

The project is estimated to produce 92.2Mt during its estimated production life of approximately 17 years.

The project will help meet the growing global demand for bauxite, particularly in China, as a result of the ban on bauxite export by Indonesia, the world’s biggest bauxite exporter and one of the world’s biggest bauxite producers.

In February 2017, Metro Mining acquired Gulf Alumina and merged Gulf’s Skardon tenements into its Bauxite Hills mine.

Bauxite Hills Project geology and reserves

The project integrates two bauxite plateaus, namely BH1 and BH6, located adjacent to the Skardon River. The deposit type at the bauxite mine is lateritic bauxite derived from the weathering of aluminous sediments in a tropical to sub-tropical environment, with the mineralisation being flat lying and tabular in form at both locations.

The mineralisation at BH1 covers an area of approximately 6.7km², whereas BH6 covers a mineralised area of approximately 8.4km². The average thickness of the bauxite mineralisation is 2.2m in BH1 and 1.8m in BH6, whereas the average overburden thickness is 0.6m in the former and 0.2m in the latter.

The integration of Gulf Alumina’s Skardon River Project reserves has increased Metro’s reserves base to 96.5Mt containing 49.9% alumina (Al2O3) and 12.9% reactive silica (SiO2). The resources are estimated to be 128.8Mt comprising 49.9% Al2O3 and 13.3% SiO2.

Mining and screening at Metro Mining’s flagship project

The project employs a shallow, free-dig mining of bauxite ore, with no drilling and blasting required. The initial mining areas were pre-stripped, where topsoil and vegetation were removed by clear and grub activities, following which front-end loaders mined the bauxite ore. The ore was screened to a size of 100m prior to haulage.

Haulage, loading and transportation

The haulage of the screened bauxite ore to the stockpiles located adjacent to the BLF, located 7.1km from the BH6, was performed using 150t triple road trains, whereas the loading of the bauxite ore from the stockpile to the BLF was made by using two front-end loaders.

The bauxite ore from the BLF was conveyed to barges and towed to an anchorage point offshore, where they are loaded by cranes into 50,000t to 60,000t vessels for export. A fleet of two towing tugs, two support tugs and four 3,500t dumb barges is also deployed.

Infrastructure at the North Queensland bauxite mine

In addition to the construction of the screening plant and the BLF, the project involved the installation of navigational aids and cyclone moorings for the tug and barge fleet, construction of barge facilities, and construction of haul roads.

Ancillary infrastructure at the site includes accommodation camps, administrative offices, workshops, communications and storage facilities, a sewage treatment plant, and water supply facilities.

Financing

Sprott Private Resource Lending (Sprott) and Ingatatus are providing debt finance facilities of approximately A$40m for the development of Bauxite Hills mine.

Bauxite off-take from Bauxite Hills mine

In October 2016, Metro Mining signed a binding bauxite offtake agreement with Xinfa Group for a total of 7Mt for four years, which includes 1Mt in the first year and 2Mt in the next 3 years from the project.

The company has previously signed an off-take memorandum of understanding (MoU) with Xinfa Group for the offtake of the product from Bauxite Hills for a period of five years.

On 30 May 2017, Metro Mining signed a non-binding letter of intent (LoI) with Shandong Aluminium (Lubei), the fifth largest bauxite importer in China, for the offtake of 0.5Mtpa to 1Mtpa for an initial three years commencing from 2018.

Key players involved

In addition to the definitive feasibility report for the project, MEC Mining also prepared the bankable feasibility study (BFS) of the bauxite mine with the support of various specialist consulting firms. The BFS also includes the Gulf’s existing infrastructure.

CM Group assessed the project’s product for marketability. Drilling works at the two sites were performed by Wallis Drilling, while the drill hole collar positions were surveyed by Fugro Spatial Solutions.

Metro Mining engaged SAB Mining for conducting civil works during the construction phase of the Bauxite Hills mine, and also awarded the mining contract in September 2017.

Process 26 designed the BLF conveyor system, while CSF Steel Fabricators is responsible for the fabrication.

Foreshore Marine was awarded the marine installation contract, while Falck was contracted for the paramedic and medical supplies at the bauxite project.