The Meliadine Gold Project is located in the Kivalliq District of Nunavut, approximately 25km northwest of Rankin Inlet on the west coast of Hudson Bay, Canada. It is Agnico Eagle Mine’s biggest development project based on reserves and resources.

Agnico Eagle Mines has 100% ownership in the project as a result of the takeover of Comaplex Minerals in July 2010. Agnico completed and filed the National Instrument 43-101 (NI 43-101)-compliant updated technical report for the project in March 2015.

The project is estimated to have an initial production life of nine years based on the designed capacity of the process plant, which is estimated to process an average 3,000 tonnes per day (tpd) of ore in the first three years and 5,000tpd of ore in the succeeding years, with production averaging at approximately 326,000oz and 362,000oz of gold dore respectively.

The initial capital cost to bring the mine into production is estimated to be $911m. The mine is expected to have an initial production life of nine years.

Geology and mineralisation at the Nunavut gold mine

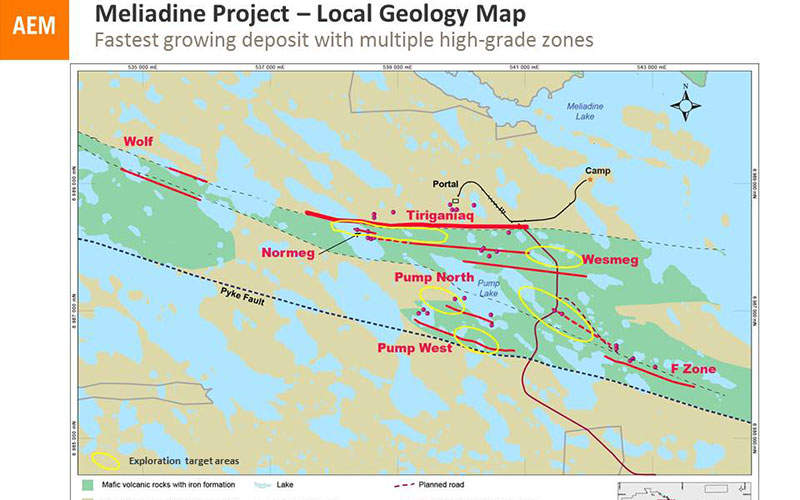

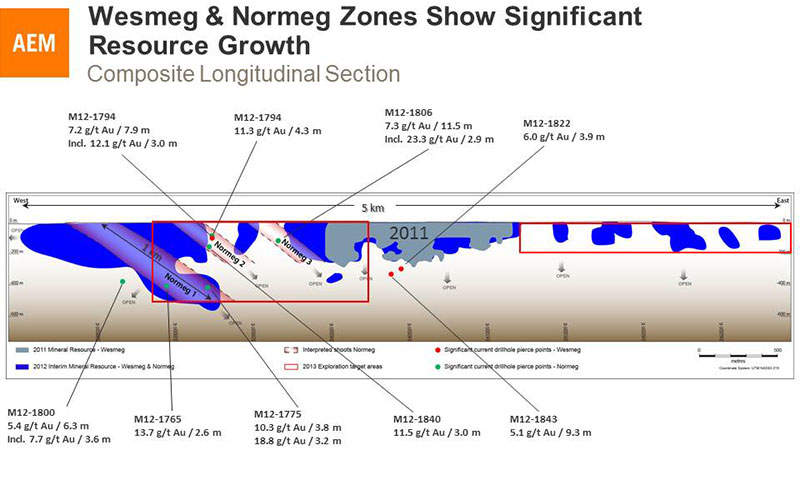

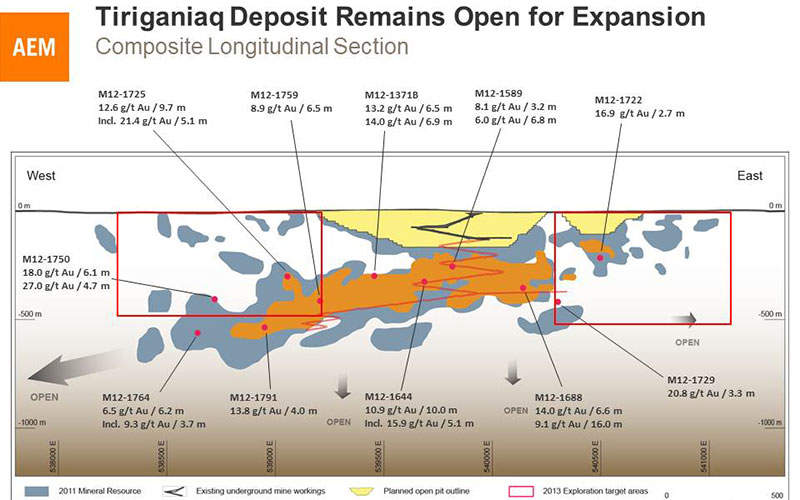

The project envisages the development of the main Tiriganiaq deposit and parts of the Wesmeg deposit. Five more deposits have been identified at the site, but the resources have not been converted into reserves yet.

The seven deposits cover an area of approximately 80ha within the Archean Rankin Inlet Greenstone Belt, which consists of mafic volcanic rocks, felsic pyroclastic rocks, sedimentary rocks and gabbro sills of approximate 2.7bn years old that have been polydeformed and metamorphosed.

Gold mineralisation is primarily hosted in mesothermal quartz-vein-dominated gold systems in sheared and folded rocks of Archean turbidites, iron formation and volcanic rocks. The deposits contain gold-bearing lodes of quartz vein stockwork, laminated veins and sulphidised iron formation with strike lengths of up to three kilometres.

Meliadine gold project reserves

As of December 2014, the Nunavut gold mine was estimated to hold proven and probable mineral reserves of 13.9Mt, containing 3.3Moz of gold grading 7.44g/t.

The measured and indicated mineral resources are estimated to be 20.2Mt containing 3.3Moz of gold grading 5.06g/t, whereas the inferred mineral resources are estimated to be 14.1Mt containing 3.5Moz of gold grading 7.65g/t.

Mining and processing

Agnico Eagle proposes to develop the two deposits through two open-pits and an underground operation.

The long-hole mining method has been proposed for the underground mine. Underground access will be by decline and the primary stopes will be backfilled with cemented pastefill while the secondary stopes will be backfilled with dry rockfill.

A conventional truck / shovel operation has been proposed for the two open-pits. Further, controlled blasting will be performed to minimise the mining fleet.

The processing plant proposed for the project is a conventional gold circuit integrating crushing, grinding, gravity separation and cyanide leaching with a carbon-in-leach circuit (CIL), followed by cyanide destruction and filtration of the tails for dry stacking. The gold recovery rate is expected to average at 96%.

Infrastructure for Agnico Eagle’s gold mine

Existing infrastructure at the site include a 25km all-weather access road connecting the mine with the town of Rankin Inlet and a temporary accommodation camp for 196 personnel. The facilities were constructed as part of the project’s pre-development phase.

The electricity and heating requirements will be met by a new 31.3MW diesel-fuelled power plant.

Fresh water required for the pre-construction phase is being sourced from the Meliadine Lake under a licence obtained from the Nunavut Water Board (NWB). The required fresh water for the life of mine (LOM) is also expected to be sourced from the Meliadine Lake, for which a separate licence is being sought.

Other major infrastructure will include ore stockpiles, waste rock storage pads, a tailings storage facility, fuel storage tanks, water and wastewater treatment plants, an industrial incinerator, a 24,000t capacity explosives plant, mine ventilation and heating systems, and specially-designed insulated buildings primarily housing a laboratory, core shack, permanent accommodation camp and administrative offices.

The project will also involve the construction of a fuel tank farm at the port of Rankin Inlet.

Key players involved

Golder Associates assisted the project owner for the geomechanical data collection, mine design analyses and the open-pit slope design for the main deposit, whereas Knight Piésold and Mine Design Engineering (MDEng) provided geo-mechanical support for the underground mine design of the main deposit.

BBA provided engineering support and cost estimate for the main infrastructure design, EBA (Tetratech) provided engineering support for the tailing facility, the land farm, the landfill and the mine’s water management infrastructure, whereas Stantec provided engineering support for the design of the underground infrastructure and ventilation systems.