Located near Cloncurry in northwest Queensland, Australia, the Lorena gold project was acquired by Malachite Resources in 2010. Malachite operates the mine through its wholly owned subsidiary Volga Elderberry (VEPL).

The Queensland Department of Environment and Heritage Protection granted the environmental authority (EA) permit for the project in May 2014. The project has the potential to extend its mine life with the development of an underground operation beneath open-cut operation.

Mining works commenced in October 2017, while the processing plant was also commissioned in the same year. Ore processing at Lorena commenced in February 2018, and first gold was poured at the end of March 2018.

The mine is expected to produce between 30,000oz and 35,000oz of gold from the open-cut operation during its anticipated production life of 18 months.

Geology and mineralisation of Lorena gold project

Located approximately 15km to the east of Cloncurry, the project is hosted within the mining lease ML7147, which is one of the six mining leases held by Malachite Resources. The company also holds two exploration permits (EPM18189 and EPM18908) in the region.

Gold mineralisation at Lorena is hosted within a south-west steeply dipping fault system comprising silicified and brecciated shale and siltstone of the Toole Creek volcanic formation. The mineralisation is classified as massive and occurs in conjunction with stringer sulphide type and copper-gold mineralisation.

The mineralisation is developed within steeply south-dipping shear zones, up to 12m-wide striking east-west and northwest-southeast within the license area. The zones host sedimentary units, breccias and fault gouge with quartz-carbonate-sulphide pods.

The sulphide pods are made up of arsenopyrite, pyrite, pyrrhotite, chalcopyrite and bismuthinite.

The deposit also hosts minor copper mineralisation within the main gold zones.

Lorena project reserves

The Lorena gold mine is estimated to contain JORC-compliant mineral resources of 179,500t, while contained gold is estimated at 56,600oz grading 2g/t.

Lorena gold project development details

Malachite Resources entered a 50/50 joint venture agreement with BCD Resources (supported by MKS Switzerland) in July 2013 for the first stage development of the gold mine and to construct a 120,000t capacity concentrate plant for treating the produced ore.

The JV was, however, terminated in May 2015 as BCD did not go ahead with the mine development.

Malachite reached an agreement with Ore Processing Services (OPS) in March 2016 for developing and operating a modular mineral processing plant to treat the ore produced at Lorena. Malachite also reached a partnership and funding arrangement with OPS and Cloncurry Gold Recovery Management (CGR) for the development of the project.

Malachite will hold a 55% joint venture interest in the project, while CGR and OPS will hold 30% and 15% respectively, as part of the agreement. Chinova Resources holds a 70% stake in CGR, while private mining and contracting company BIM Gold holds the remaining 30%.

BIM Gold is acting as the mine operator, while OPS is responsible for ore processing.

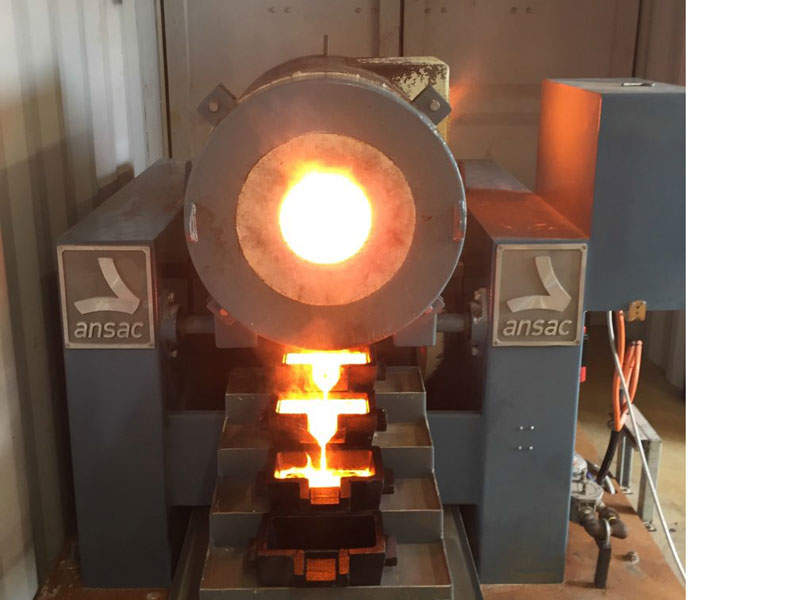

OPS reached an agreement in September 2016 to acquire the stake of MKS Precious Metals (Australia) in the concentrate plant developed by BCD at Lorena site. The company constructed the 200,000 tonnes per annum (tpa) Lorena concentrate plant as well as supplied a modular carbon-in-leach (CIL) circuit following the agreement.

Mining and processing of ore at Lorena

Conventional open-pit mining method, including drilling and blasting to remove waste rock, is applied in the first stage of Lorena mine. An estimated 250,000t of ore is proposed to be mined from the open-cut operation.

Conventional underground mining methods at a depth of 200m will be used in stage two underground development of the mine.

Run-of-mine (ROM) ore passes through a two-stage crushing process, using a jaw crusher and a cone crusher, before passing through the milling circuit. The circuit operates at 20 tonnes per hour (tph) and comprises a grinding mill operating in a closed circuit.

Slurry from the grinding circuit will be directed to the flotation circuit through a trash screen. At the flotation circuit, the material passes through roughing, scavenging and cleaning processes. The concentrate then passes through to the magnetic separation circuit, where the pyrrhotite is removed by using LIMS drum magnetic separators.

The project is anticipated to produce approximately 27,600t of gold concentrate from the open-pit operation.

Sale of gold produced at Lorena

Gold concentrate produced from the first stage open-cut operations at Lorena will be sold to MKS Switzerland, under a letter of offer signed in July 2015.

Financing

Malachite Resources entered a financing term sheet with ResCap Investments in October 2016 for a $5m loan facility for developing the Lorena gold project.

Infrastructure facilities at Lorena

The mine can be accessed from the Lorena mine through the Flinders Highway and the unsealed Fisher Creek Road.

Power is being supplied by three 600kVA generators installed near the new processing plant.

Water required for the mine is provided by the nearby production bores, while potable water is collected from groundwater pumped into the raw water tank.

Contractors involved

O’Kane Consultants was engaged as the environmental consultant for the gold project.