The Lac à Paul phosphate mine is located approximately 200km north of the city of Saguenay in the Saguenay-Lac-St-Jean region of Québec, and approximately 650km north-east of Montreal, covering an area of more than 27,000ha (270km²).

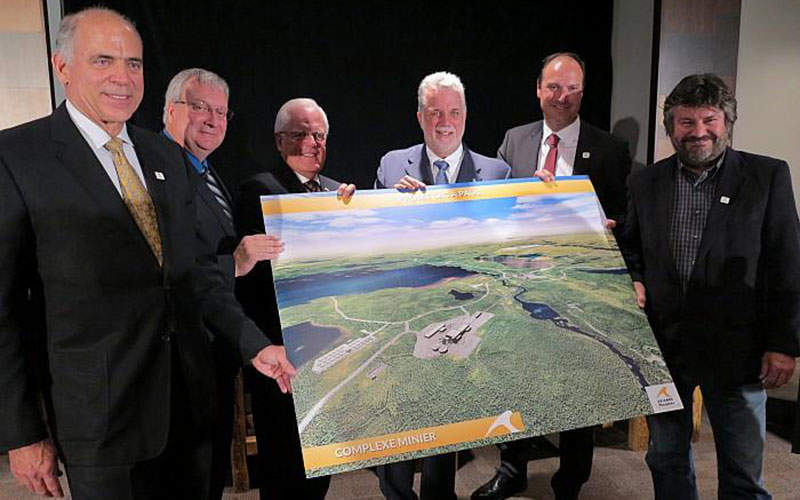

Arianne Phosphate is the 100% owner of the project, which is claimed to be the world’s biggest greenfield phosphate rock project and the biggest mining project to be implemented in a decade in Quebec.

The feasibility study for the mine’s development was concluded in October 2013, the environmental impact assessment (EIA) was submitted in June 2013 and the project was approved by the government of Quebec in December 2015. The project involves an investment of $1.2bn, which includes $982.5m for the mine development and $232.2m for the development of the concentrate transport system.

It is expected to generate approximately 2,200 direct and indirect jobs during the construction phase, approximately 1,000 jobs during the operational phase, and $12.5bn in economic benefits to the region. The estimated life of the phosphate mine is 26 years.

Lac à Paul project location and geology

The Lac à Paul project is located in the Lac-Saint-Jean Anorthositic Suite (LSJAS), which forms the central part of the Grenville Geological Province.

The project involves the development of the Paul Zone located on the northern part of the property. The apatite deposit features a nelsonite stratabound lense in the north, a mineralised anorthositic gabbro (apatite gabbro) in the south and a third mineralised envelope composed of a combination of the two in the eastern part of the zone. The mineralised envelope is approximately 3,700m-long and 400m-deep.

Lac à Paul mine reserves

As of November 2011, the Paul Zone was estimated to contain combined measured and indicated resource of 590 million tonnes (Mt) at an average grade of 7.1% P₂O₅ (phosphorus pentoxide), with a 4.0% P2O5 cut-off grade, and inferred resource of 9.1Mt at an average grade of 5.89% P₂O₅, with a 4.0% P₂O₅ cut-off grade.

The proven and probable mineral reserves are estimated to be 472.09Mt, grading an average of 6.88% P₂O₅ with a 3.5% P₂O₅ cut-off.

Mining and processing at Lac à Paul phosphate mine

The pit will be mined using conventional methods including drilling, blasting, loading, and hauling using shovels and trucks.

The processing plant will integrate a primary crusher, a coarse ore storage silo (CSO), a beneficiation plant, a two-stage closed grinding circuit including a 15,000kW semi-autogenous grinding mill and two secondary 11,000kW ball mills, a low-intensity magnetic separation (LIMS) circuit, a column floatation circuit, a tailings thickener, and a flash dryer.

The processing plant will be designed for a capacity of 55,000 tonnes per day (tpd) to produce three million tonnes per annum (Mtpa) of phosphate rock concentrate grading 38.6% P₂O₅, with concentrate P₂O₅ recovery of 90%.

Infrastructure for Arianne Phosphate’s flagship project

The electricity required for the project will be sourced from a new substation at the neighbouring Chute des Passes power plant, owned by Rio Tinto Alcan, and conveyed via a 45km-long 161kV transmission line. The power transmission facilities will be owned by Hydro-Québec.

Major infrastructure at the site will include a tailings storage facility (TSF) 2km away from the concentrator, a waste rock dump, a permanent work camp, a water intake area and a water treatment facility.

In addition to the main crusher and concentrator buildings, the project will also involve the construction of additional buildings to house administrative offices, a server room, a nursing station and a cafeteria, a laboratory, worker showers and lockers, a maintenance garage, a fuel storage and distribution area, a gatehouse and emergency response room, and a warehouse shelter.

Concentrate transportation

The phosphate concentrate will be transported from the mine site by trucks operating on existing logging roads to a proposed deepwater port located on the Saguenay River. The roads will be upgraded as part of the project.

Up to 61 triple-axle trucks with a width of 3.7m, equipped with 120t covered trailers are expected to be employed to transfer the phosphate concentrate.

Key players involved

The project’s feasibility study was conducted by Cegertec WorleyParsons with assistance from Dessau for the tailings storage and impoundment and water management, and Ernst & Young for the financial modelling and economic analysis, which was certified by SGS Canada.

The waste rock dump design and environmental impact assessment were performed by Genivar in collaboration with Hydro Resources, Journeaux Associates, URSTM, Jenike & Johanson, Outotec, FLSmidth, Dessau-Groupe Conseil Nutshimit, CRU International, and Integer Research.

Goldminds Geoservices prepared the mineral resource estimates. Cegertec WorleyParsons was assisted by COREM and Jacobs Engineering Group (Jacobs) in conducting the metallurgical test work, including pilot test work for the process design, while L. Nardella supported with the cost estimation and project execution planning.