The Kutcho copper and zinc project is an open-pit and underground mine being developed in British Columbia, Canada, by Kutcho Copper.

The project comprises three deposits, namely the Main, Sumac, and Esso. Kutcho Copper released a feasibility study (FS) for the copper-zinc project in November 2021. The project is estimated to produce 17.3 million tonnes (Mt) of ore over its 11-year mine life. It will produce copper and zinc as primary concentrate products, in addition to recovering minor quantities of gold and silver.

The Kutcho project is estimated to involve a pre-production capital investment of approximately C$483m ($387.63m). The construction decision for the mine development is expected to be finalised by the third quarter (Q3) of 2024.

Kutcho copper and zinc project location and geology

The Kutcho copper and zinc project is located approximately 100km east of Dease Lake in northern British Columbia, Canada. The mining property lies within the territories of the Tahltan Nation and Kaska Dena Nation.

The geological setting of the project area comprises the King Salmon Allochthon structural/stratigraphic belt, a narrow belt associated with Permo-triassic volcanic rocks and Jurassic sediments. The belt is bounded by two north-dipping thrust faults, namely the Nahlin fault to the north and the King Salmon fault to the south.

Kutcho project reserves

The proven and probable open-pit and underground mineral reserves at the Kutcho copper and zinc project are estimated at 17.34Mt grading 1.58% copper, 2.31% zinc, 27.9g/t silver, and 0.39g/t gold, as of November 2021.

Mining methods at Kutcho copper and zinc project

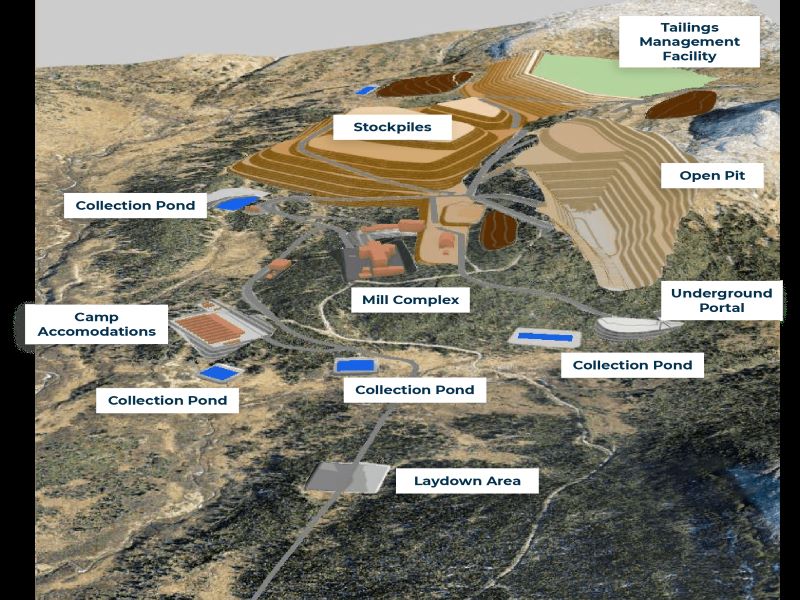

The Main deposit is planned to be primarily operated as an open-pit mine with traditional shovel and truck operation, while the deeper sections of the deposit will be mined using underground mining methods of longitudinal long-hole open stoping (LLHOS) with cemented rock fill (CRF). The Esso deposit will also be developed as an underground mine using LLHOS.

The underground portion of the Main deposit will be located below the Main open-pit, with a 25m crown pillar separating the two. An initial 340m-long decline will be installed to provide access to the underground portion. The underground operation of the Main deposit is not expected to have much of an interference with the open pit as it will be completed during the initial years of the open-pit operation.

The Esso deposit hosts higher average grades of copper and zinc ore compared to the Main deposit. The Main and Esso deposits are planned to be accessed via a single portal. The Esso deposit will start at approximately 400m below the surface with access from a 1,800m decline extending from the Main ramp.

The FS considers the plan to start open-pit operations during the construction period. A two-year ramp-up period will allow the project to reach an estimated average steady production rate of 1.8 million tonnes per annum (Mtpa). The estimated life of the open-pit operation is eight years with approximately 14.5Mt of ore production. The underground development will begin two years before the start of production. The Main underground mine will have a projected mine life of three years, with an estimated ore production of 0.6Mt at an average rate of 600 tonnes per day (tpd).

The Esso underground deposit is expected to enter production in year two before ramping up to full production in the following year. It is estimated to produce approximately 2.2Mt of ore at an average rate of 0.3Mtpa or 860tpd over a mine life of nine years.

Kutcho copper and zinc ore processing capabilities

The run-of-mine (ROM) ore will be crushed to more than 12.5mm and sent to an X-ray transmission (XRT) ore sorting circuit, which will feed the milling and flotation circuit. The rejects from the ore sorter will be used for the underground CRF.

The sorted ore will be ground in the semi-autogenous (SAG) and ball mill to reduce the size to 55µm.

The processing plant will also include sequential flotation of copper minerals, followed by zinc minerals to recover the metals from the ore. Sulphur dioxide (SO₂)-based reagents will be utilised in the flotation process during the initial depression of zinc and pyrite in the copper flotation circuit. The zinc will be reactivated using specific collector and frother reagents before it is sent to the zinc flotation stage.

The final copper concentrate will be produced by regrinding and upgrading the copper rougher concentrate in a cleaner stage, while the final zinc concentrate production will be achieved by three stages of cleaning. The flotation tailings will be dewatered before being pumped to the tailings management facility (TMF) for storage.

The Kutcho copper and zinc project is estimated to produce 533 million pounds (Mlb) of copper and 841Mlb of zinc concentrates as primary products, as well as 10.6 million ounces (Moz) of silver and 129,000oz of gold as byproducts.

Infrastructure of the Kutcho project

Access to the site during construction and operations will be via an upgraded 120km-long Boulder Trail gravel road, which is linked to the Stewart-Cassiar Highway 37 directly south of Dease Lake. A 1,000m-long airstrip is also located approximately 10km away from the mine site.

The project will generate clean power for its operations using four 2.5MW liquefied natural gas (LNG)-powered generators and an additional one on standby. A 2MW diesel generator will be used to meet the occasional start-up requirements of the plant.

Contractors involved

Mining consultant CSA Global, an ERM Group company, led the FS for the project. The company provided the mineral reserve estimate and conducted a study related to mining, hydrology, and site water balance.

Canadian firm Mineit was responsible for mining engineering, processing and recovery, financial modelling, and reserve estimation, as part of the FS. Allnorth Consultants, a multi-disciplinary engineering and construction services consulting company, provided process plant and infrastructure design and engineering.

Piteau Associates, a mine geotechnical engineering and waste rock management company, was contracted to provide engineering and design studies for waste and tailings management.

Canada-based consulting firm SIM Geological was engaged for resource modelling and estimation while Terrane Geoscience was responsible for mining geotechnical engineering. The main access road design and engineering study was performed by OnSite Engineering.

ABH Engineering, a mineral processing specialist, and TOMRA Sorting Mining, a sensor-based sorting systems manufacturer, were engaged to conduct ore sorting test work for the project.