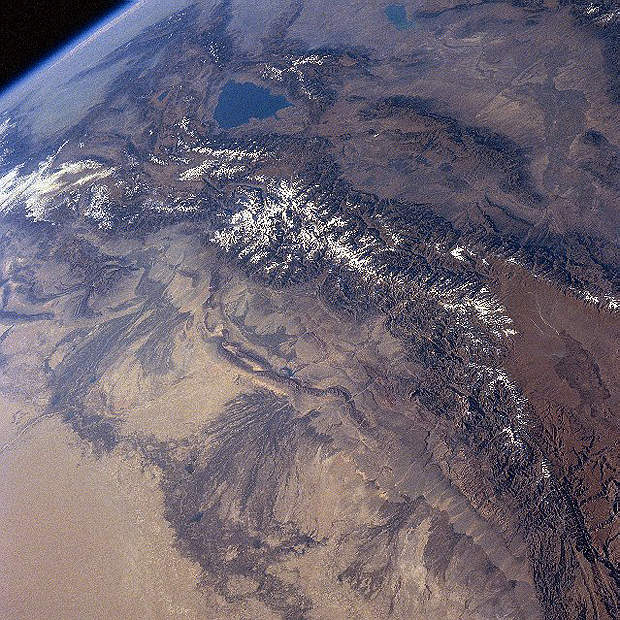

The Kumtor gold mine is located in the Tien Shan Mountains in the Kyrgyz Republic, about 350km south-east of the capital Bishkek and about 60km north of the international boundary with China.

The mine is owned by Centerra Gold through its wholly owned subsidiary Kumtor Gold Company. It is the largest gold mine project operated by a Western company in the Central Asian region.

In June 2012, the project was caught in the middle of a controversy over charges of environmental problems and poor management by Kumtor Gold Company. The controversy led to a review of the company’s operating license.

The Kyrgyzstan parliament, however, voted in favour of renewing the operating license. It also approved a planned increase in interest in the mine from 33% currently owned by the government.

Geology

The gold deposit is located in the southern part of Tien Shan metallogenic belt extending from western part of Uzbekistan to Tajikistan and Kyrgyz Republic towards north-western China. The mine area is prevailed by thrust slices consisting of older rocks. The slice featuring gold mineralisation is formed by Vendian meta-sediments. Kumtor Fault Zone (KFZ) is a dark-grey to black, graphitic gouge and metamorphic rock zone dipping to the south-east at moderate angles.

The structural geology at the mine was developed through four main deformation stages occurring between pre-carboniferous and tertiary period. The open-pit gold mine consists of a central pit and two satellite deposits including the Sarytor Deposit and the Southwest Deposit. High-grade underground Stockwork and SB Zones located directly below the central pit form part of the Kumtor Gold Project.

Mineralisation

Gold mineralisation occurred in the Vendian sediments from late Carboniferous to early Permian age. The mineralisation was found over a strike distance of more than 12km. The main accumulation was in the Central Deposit and the other known events were the Southwest Deposit and the Sarytor Deposit.

Mineralisation occurred in four main pulses and metasomatic activity was carried out through phases two and three. The activity affected substantial volumes in the Stockwork Zone of the Central Deposit.

Primeval gold and gold-bearing minerals with an average size of just 10 microns are found in pyrite. Post-ore faults frequently contain substantial amounts of graphite and various preg-robbing carbonaceous materials.

Kumtor reserves

The proven reserves at Kumtor are estimated at 1.65mt, containing approximately 113,000oz of gold graded at 2.1g/t. As of December 2011, the probable and proven reserves were 6.3moz of gold.

The measured resources are estimated at 18.4mt, containing 1.4m oz of gold graded at 2.4g/t. The indicated resources are estimated at of 10.3mt, comprising 760,000oz of gold graded at 2.3g/t.

Mining and processing

The gold deposit is mined using conventional open-pit mining methods. The mine currently produces about 15,000t of ore and 220,000t of waste per day. The mining operations are carried out by two 12-hour shifts per day, year-round. The Kumtor mill has the design capacity to process 4.8mt of ore a year but throughput has reached 5.6mt a year.

The milling process at Kumtor includes crushing, grinding, pyrite flotation and re-grinding of flotation concentrate.

Gold is recovered from the re-ground concentrate and flotation tails by two separate carbon-in-leach (CIL) circuits, while final gold recovery is achieved by electro-winning and refining. The entire process is monitored and controlled by a Foxboro System.

In 2005, an ultra-fine grinding mill (ISA-Mill) was installed at Kumtor to achieve higher recoveries.

Production

The gold production at Kumtor reached 583,156oz in 2011. The mine produced over 568,000oz of gold in 2010 compared to 525,000oz in 2009. It produced over 8.4moz of gold between 1997 and end of 2011.

Costs

In 2009, the production costs per tonne of ore milled were estimated at $41.80. Total cash costs incurred per ounce were $460.

Environment

The environmental management system adopted at Kumtor ensures that the operations are carried out in compliance with the regulations of Kyrgyz authorities. The tailings management facility at the mine includes two tailings lines, a tailings dam, an effluent treatment plant and two diversion ditches.

Local construction materials and agricultural produce are used by the company wherever possible. A Reclamation Trust Fund under World Bank Environmental Guidelines has been set up at Kumtor for remediation at the end of the mine life.