The Kiaka gold project located in the south-east part of Burkina Faso in West Africa is being developed as an open-pit mine.

West African Resources (WAF) holds a 90% stake in Kiaka while the Government of Burkina Faso retains the remaining 10% interest. West African Resources acquired its stake in the project from B2Gold and their partner, GAM S-Mining in November 2021.

The feasibility study for the project was completed in August 2022. An updated feasibility study was announced in July 2024.

The project has an estimated life-of-mine of 19.5 years, with an initial capital investment of $565.6m.

The project is estimated to have an annual production capacity of 258,000oz in the first five years. Annual production will average 234,000oz over the mine life.

The first production is scheduled for the third quarter (Q3) of 2025.

Kiaka gold project location

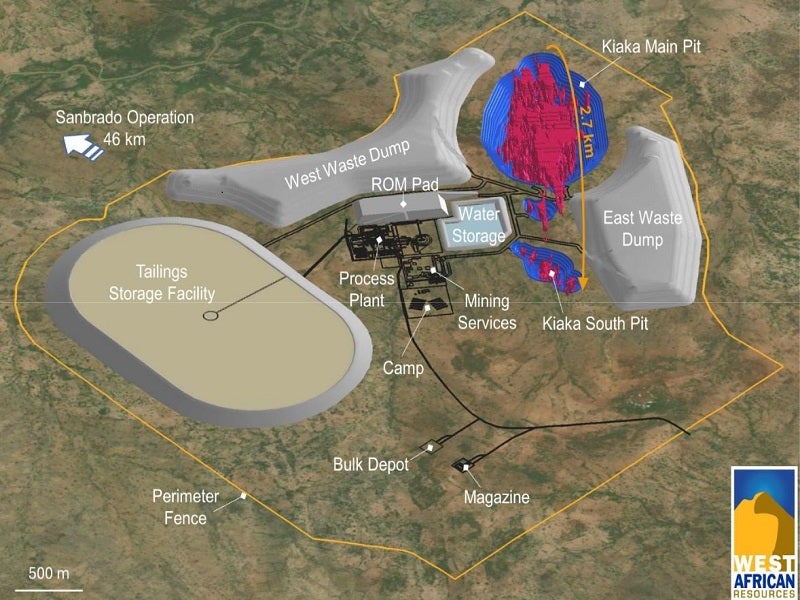

The Kiaka gold project is located 45km south of WAF’s flagship Sanbrado Gold project in Burkina Faso and about 110km southeast of the capital Ouagadougou.

The project lies within a mining permit of an area of 54km².

Geology and mineralisation

The Kiaka deposit is located within the Lower Proterozoic rocks at the confluence of the Tenkedogo Greenstone Belt and the Markoye Fault zone in the southern part of Burkina Faso.

The deposit lies beneath a layer of saprolite that can be up to 20m thick, with the primary occurrence of gold mineralisation found in the underlying fresh rock.

The Kiaka gold project encompasses the Kiaka Main and Kiaka South deposits, with the Kiaka Main deposit holding over 98% of the ore reserve.

The gold mineralisation occurs in the tightly folded and sheared mafic volcanic and volcaniclastic sedimentary rocks. The gold mineralisation is present within a shear zone that dips sub-vertically to steeply towards the southwest.

Reserves

The probable reserve at the Kiaka gold project is estimated to be 164.1 million tonnes (t), grading 0.9g/t of gold with 4.76 million ounces in contained gold, as of July 2024.

Mining method

The mining operations will be carried out using conventional open-pit mining methods with a strip ratio of 1.8: 1.

Owing to the extensive mineralised zone, some blasting can be conducted on 10m benches while more selective areas will require blasting on 5m benches.

The operational framework encompasses drilling and blasting near the surface.

The parameters for drilling and blasting have been chosen to address the relatively hard rock mass characteristics and the precision needed for ore extraction.

The Kiaka Main pit will have a maximum length of 2km and a width of 900m with a maximum depth of 460m. A minor sub-pit will be located at the southern end, which will be mined independently.

The main pit will be mined in three pit stages to reduce waste mining while providing slightly higher-grade ore.

The smaller Kiaka South pit will measure 650m x 350m in length and width with a depth of 130m.

The mining fleet will consist of a mix of Caterpillar 6015 (140t class) and 6020 (230t class) hydraulic excavators, which will be paired with Caterpillar 777 (95t class) haul trucks.

Also, a combination of top hammer (Sandvik Panterra DP1500) and down-the-hole hammer (Sandvik Leopard DI650) drill rigs will be utilised.

Ore processing

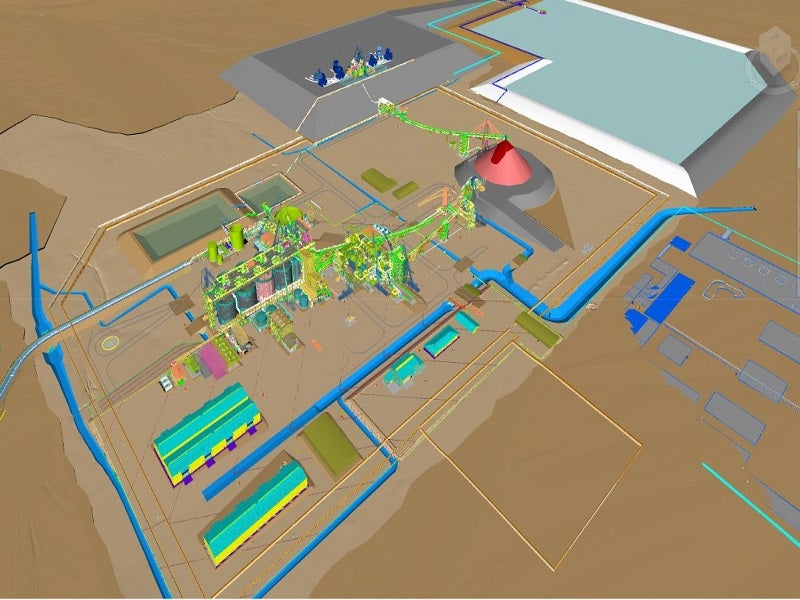

The Kiaka process plant is set to have a nameplate throughput of seven million tonnes per annum (mtpa) and will operate with an availability of 8,000 hours annually.

Its nominal capacity is 875 tonnes per hour.

The production schedule for the mine anticipates that 60% of the ore will be directly tipped while the remaining 40% will be rehandled into the crusher using a front-end loader.

The process plant will include several circuits: a primary gyratory crushing circuit with a designed throughput of 1,229 dry tonnes per hour.

The open stockpile for crushed product with a total capacity of 57,000t, and three apron feeders in a reclaim tunnel will supply ore to the milling circuit via a conveyor.

Additionally, there will be an emergency reclaim system with a dedicated apron feeder next to the stockpile.

A grinding circuit comprising Semi-Autogenous Grinding, ball, and Pebble Crushing has been modelled to process 8.4mtpa.

Further features include a high-rate leach feed thickener to improve classification efficiency in the milling circuit and reduce the leaching circuit’s volume needs.

A pre-oxidation tank, complemented by an oxygen plant and proprietary oxygen injection technology, will treat the thickener underflow.

The carbon-in-leach circuit will consist of eight leach-adsorption tanks, ensuring a 36-hour residence time for the ore.

For metal recovery and refining, the plant will have a split Anglo American Research Laboratories elution circuit, electrowinning cells, and a smelting facility.

The tailings storage facility will be constructed 0.5km north-east of the process plant.

Site infrastructure

The project is accessible via the N5 road from Ouagadougou to Manga followed further by a 40km laterite gravel road to the property.

Power will be supplied by connecting to the national grid operated by SONABEL.

The most feasible connection point is a junction from the existing 225kV transmission line that runs from Ghana to Ouagadougou.

Raw water will be sourced from the Bagre dam on the Nakambe river, located roughly 3km east of Kiaka.

A 304-person accommodation camp will be constructed 0.5km to the south-west of the processing plant.

Contractors involved

The process plant design was prepared by engineering, construction, and management services provider Lycopodium Minerals.