The Keliber lithium project is located in Central Ostrobothnia, Western Finland. Finnish mining company and Nordic Mining associate Keliber Oy is developing the project, which is expected to be the first mine in Europe to produce high-grade lithium carbonate.

The pre-feasibility study (PFS) of the lithium project was completed in March 2016, and a definitive feasibility study (DFS) was completed in June 2018. Production is expected to start by early-2019.

The project is estimated to require a €255m ($297m) investment and will produce 11,000 tonnes per annum (tpa) of battery-grade lithium carbonate (Li2CO3) from spodumene-rich pegmatite deposits. It is anticipated to process 7.41 million tonnes (Mt) of ore through its 13-year mine life and produce 1.48Mt of spodumene concentrate.

Keliber Oy proposes to purchase additional spodumene concentrates from third parties and increase the mine life by seven years.

Keliber lithium project location

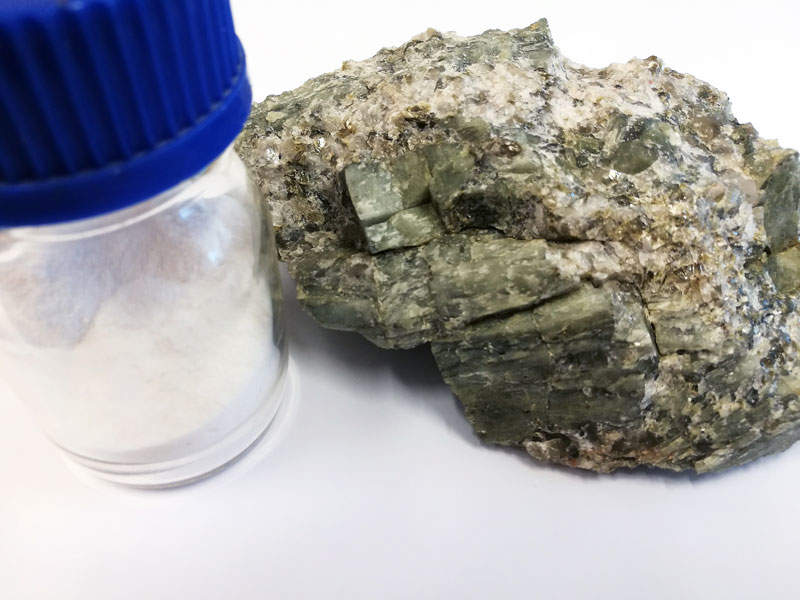

The project is located within the Kaustinen-Kokkola area, an integral part of the paleoproterozoic Pohjanmaa Schist belt, which is a 350km-long and 70km-wide arc-shaped structure formed between the Central Finland granite and the Vaasa Migmatite complexes.

Mica schists and gneisses are the most common rock types found within the Pohjanmaa Belt, and are intercalated with meta-volcanic rocks. The supracrustal rocks found in the region are classified into two groups namely Evijärvi and Ylivieska.

Keliber lithium project geology and mineralisation

The Keliber lithium project comprises four open-pit deposits, namely Rapasaari, Syvajarvi, Lantta and Outovesi, Leviakangas, and an underground deposit at Emmes. Extended underground mining will also be conducted at the Rapasaari and Lantta deposits.

The bedrock of Lantta deposit comprises pegmatite veins hosted by meta-volcanic intermediate rocks, metagreywacke schists and plagioclase porphyrite. The Syvajarvi deposit’s bedrock comprises pegmatite veins, which intrude mica schist and metagreywacke in an anticlinal structure.

The Rapasaari deposit comprises pegmatite veins intruding mica schist and metagreywackes in a synclinal system, while the Outovesi deposit hosts pegmatite veins filled with mica schist and metagreywacke. The Leviakangas and the Emmes underground deposits are covered by till and host pegmatite veins filled with mica schist and metagreywacke.

The pegmatites found at the Keliber project area belong to the albite-spodumene subgroup of LCT (Li, Cs, and Ta) pegmatite family. The paleoproterozoic albite-spodumene pegmatites cross-cut the Svekofennian supracrustal rocks, which comprise mica schists, metagreywackes, and volcano-related meta-sediments.

Keliber project reserves

The Keliber lithium project is expected to contain proven and probable ore reserves of 4.49Mt grading 1.10% Li2O.

Mining and processing of ore at Keliber

Conventional truck and shovel method of mining will be applied at the open-pit deposits at Keliber, while bench and fill mining is proposed for the underground mine. Mining at the underground deposit will be carried out from bottom upwards in 20m-high mining lifts and backfilled with waste rock from the open-pit and development drives.

The processing plant at Keliber is designed for a nominal ore throughput of 600,000tpa and a design value of 650,000tpa. The ore will be initially crushed in a primary crusher, stockpiled and transported to the concentrator at Kalavesi located in the municipality of Kaustinen.

The crushing and sorting unit of the concentrator will undertake screening, secondary and tertiary crushing apart from sorting the fine and coarse ore. The ore will then pass through a two-stage rod-ball mill grinding circuit, which operates in open circuit, while the ball mill will operate in closed circuit with wet screening.

Oversize from the wet screening will be returned to the ball mill, while the undersize will be pumped to de-sliming cyclones. Cyclone overflow will then be pumped to the tailings facility, while the cyclone underflow will be pumped to the flotation circuit.

The spodumene flotation is expected to recover 83% of the Li2O into a flotation concentrate representing approximately 26% of the ore mass. Spodumene concentrate will be stored in the concentrate storage facility before being transported by truck to the chemical plant at Kokkola Industrial Park site.

Apart from lithium carbonate, Keliber Oy will also produce analcime (sodium zeolite) as by-product, and fine-grained quartz-feldspar from the enrichment of spodumene.

Infrastructure facilities at Keliber project

Local grid company Korpelan Voima Oy will supply the electricity required for the mine, while two 4.8km-long, 20kV power transmission lines will provide power from the supplier substation to the Kalavesi site.

Raw water intake will be made from the nearby Vissavesi Lake, and then treated on-site to provide the required process and sealing water. Potable water will be sourced from the municipality water supply.

Contractors involved

GTK Mintec, Outotec and Metso conducted test work and designed the treatment route to produce lithium carbonate from spodumene.

Hatch was engaged as the technical co-ordinator of the Keliber lithium project DFS, while Pöyry Finland prepared the ore reserve estimates as part of the DFS.

Keliber has engaged Roskill Consulting Group to undertake a lithium market overview and outlook study to evaluate the market for its product.