Euromax Resources’ (Euromax) Ilovica Gold-Copper Project, covering an area of 17.1km², is located within the municipality of Bosilovo, approximately 20km east of the town of Strumica, on the western slopes of the Maleševske mountain range in southeast Macedonia.

The pre-feasibility study (PFS) for the project was completed in December 2014 and the definitive feasibility study (DFS) was completed in January 2016. First production from the gold-copper project is anticipated in late-2018.

The mine life is estimated at 20 years, during which production is estimated to average 83,000oz of gold doré and 16,000t of copper concentrates a year.

The initial investment to bring the project into production is estimated to be €431.2m ($474.3m). The project is expected to generate approximately 700 jobs during the construction phase and 500 jobs during operations.

Ilovica porphyry copper-gold deposit geology and mineralisation

The project is located within the northwest-southeast striking Cenozoic magmatic arc that covers part of Macedonia and its neighbouring countries.

The project’s porphyry system measures approximately 1.5km in diameter and is linked to a poorly-exposed dacite-granodiorite plug, positioned along the north-eastern border of the northwest-southeast elongate Strumica graben, which hosts terrigenous clastic sediments and felsic volcanic rocks dating back to 40 million years.

The deposit is controlled by major north-south cross-cutting faults and minor northwest-southeast faulting, parallel to the faulted border of the graben.

The primary sulphide mineral within the deposit is chalcopyrite, followed by pyrite, and secondary copper sulphides including chalcocite, covellite, and bornite. The deposit also hosts molybdenite, galena, and sphalerite in fewer quantities, and sulphosalt minerals such as tetrahedrite-tennantite and tellurides of gold and silver.

Reserves at Euromax Resources’ gold-copper project

The project is estimated to hold combined proven and probable reserves of 198.1 million tonnes (Mt), grading 0.32g/t Au and 0.21% Cu, and containing 2.01 million ounces (Moz) of gold and 898.9 million pounds (Mlb) of copper respectively.

The combined measured and indicated resources are estimated at 256.8Mt, grading 0.32g/t Au and 0.21% Cu, and containing 2.6Moz of gold and 1.208bn pounds of copper respectively.

Mining and processing at the Macedonian gold-copper mine

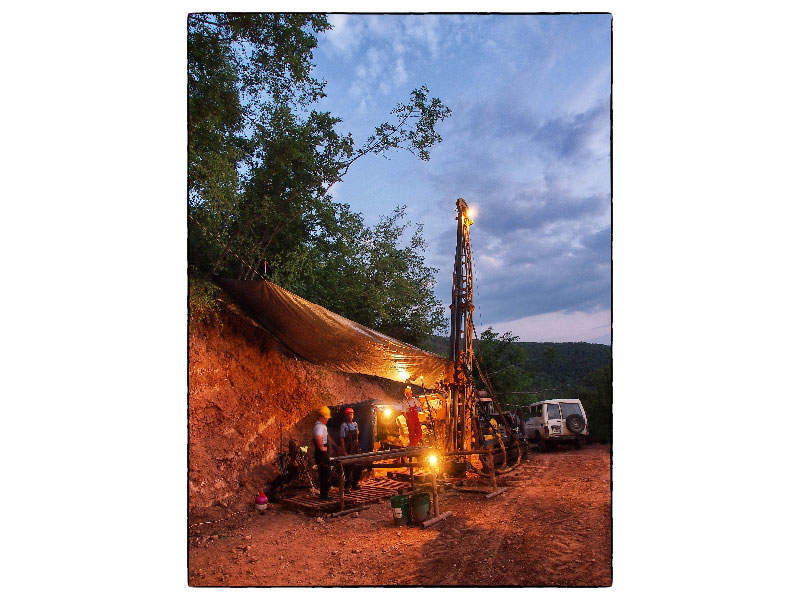

The mining method selected for the project is the open-pit mining incorporating conventional drilling, blasting, shovel and truck dump operations.

The primary mining fleet for the project will include two hydraulic 16.5m³ shovels with a fleet of 90t nominal payload rigid dump trucks, of which nine trucks will be deployed for pre-stripping at the start of operations and 19 trucks at its peak.

The project aims at supplying ten million tonnes per annium (Mtpa) of sulphide ore to the processing plant. The conventional processing plant will primarily incorporate a milling circuit featuring a semi-autogenous mill, a ball mill, and a crusher circuit, a rougher scavenger floatation circuit, a regrind circuit, a cleaner floatation circuit, leach and carbon-in-leach (CIL) circuit, a counter-current CIL circuit, an elution circuit, and an electro-winning circuit.

Infrastructure for the Ilovica Gold-Copper Project

Access to the project site is through a 3km-long paved asphalt road connecting with the M6. The project also benefits from its close proximity to major rail and port infrastructure, including airports and water bodies.

The electricity required for the project will be sourced from the existing substations at Berovo and Sushica via 110kV overhead transmission lines. A substation incorporating a 10kV switchboard is proposed to be constructed at the project site.

The exact source to meet the project’s water requirements has not been determined yet, but is likely to be harvested from stormwater and the neighbouring reservoirs and rivers. Either of the options would necessitate the construction of water storage dams at the site.

Other major infrastructure at the project site will include a tailings storage facility (TSF) with a designed storage capacity of 210Mt, an accommodation camp, an explosives magazine, a sewage treatment plant, communication facilities, and other buildings housing offices, control rooms, workshops, warehouses and an administrative complex.

Off-take agreement

Euromax has entered a non-binding agreement with Aurubis, for the latter to off-take 100% of the concentrates from the project for a term of ten years.

Key players involved

The lead consultant involved in the compilation of the DFS report was Amec Foster Wheeler, who took inputs from Tetra Tech for the geological studies and resource estimations, and DMT for the mining studies.

Golder Associates in collaboration with Faculty of Civil Engineering from St Cyril and Methodius University of Skopje, performed the environmental studies and the study for the TSF.

The hydrology and hydrogeology-related studies and the water-related studies were performed by Schlumberger Water Services.