The Hillgrove project in New South Wales state of Australia is planned to be developed via both open-pit and underground mining methods.

Larvotto Resources, an Australian mineral exploration company, acquired the Hillgrove project in December 2023 from Red River Resources.

The mine was discovered in 1857 and had a continuous production history of 30 years until 2002. The pre-feasibility study (PFS) of the project in August 2024 focused on restarting and upgrading the processing plant to expand production to 550 kilotonnes per annum.

The project is estimated to have a life of mine (LOM) of seven years, with an average gold production of 41koz and antimony production of 5.4 kilotonnes.

The pre-production capital cost for the project is estimated at A$88.5m ($57.6m), including contingencies.

After positive PFS, Larvotto approved the commencement of the definitive feasibility study (DFS), which is expected to be completed by the end of 2024.

The finalisation of DFS will enable project financing in early 2025. First ore production is anticipated by early 2026.

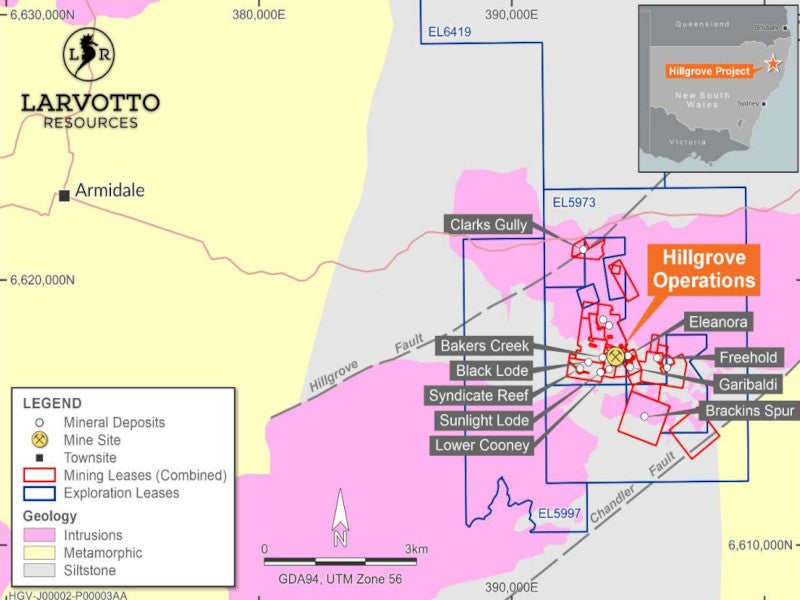

Hillgrove Project location

The Hillgrove project is located 23km east of Armidale in northern New South Wales and is strategically situated close to major infrastructure, including major highways, rail links, and regional airports.

The mining area encompasses 51 tenements covering 254km². This includes 33 mining leases, three gold leases, six private land leases, five mining purpose leases, and four exploration leases.

Overall, the project has six key mining areas- Bakers Creek, Metz Centre, Brackins Spur, Eleanora / Garibaldi, Freehold and Clarks Gully.

Geology and mineralisation

The Hillgrove project is dominated by steeply inclined north-north-west, north-west, and west-north-west mineralised structures.

The mineral field spans across three geological units: a northern monzogranite (Hillgrove adamellite), an early-stage metasediment (Girrakool Metasediment), and a late I-type diorite in the south.

Mineralisation mainly occurs as anastomosing sets of fractures, which pinch and swell along-strike with local dilational zones hosting the mineralised hydrothermal breccias.

Local mineralisation structures occur as simple single veins, quartz-wallrock breccias, zones of parallel stringer veins, and splay structures.

Hillgrove Project Reserves

The open-pit probable reserve at the Hillgrove Gold-Antimony project is estimated at 0.38 million tonnes, grading 1.9g/t of gold (Au) and 1.7% of antimony (Sb). Contained metal is estimated at 23koz of Au and 6.6 kilotonnes of Sb.

The underground proven reserve is estimated to be 0.39 million tonnes grading 2.6g/t of Au and 1.9% of Sb. Contained metal is estimated at 32koz of Au and 7.5 kilotonnes of Sb. The underground probable reserve is estimated at 2.38 million tonnes, grading 3.5g/t of Au and 1.0% of Sb. The contained metal is estimated at 264koz and 24.9 kilotonnes.

Underground probable reserves total 2.38 million tonnes, containing 264koz of Au at a grading of 3.5g/t and 24.9 kilotonnes of Sb at a grading of 1.0%.

Total reserves stand at 3.15 million tonnes, grading at 3.2g/t of Au and 1.2% of Sb. The contained metal is estimated at 320koz of Au and 39 kilotonnes of Sb as of August 2024.

Open-pit mining

The project will be mined using both open-pit and underground mining methods with the majority of the mining activity being predominantly underground.

Surface operations will feature two open pits extracted early in the project life to supplement underground production and provide construction material for infrastructure.

Open pits will be mined at the top of Garibaldi and Clarks Gully, prior to the commencement of underground mining at each area.

The two open pits will be mined using conventional drilling, blasting, loading, and hauling systems. Mining at Garibaldi will include the extraction of cut material from the basin of Tailing storage facility (TSF2)-West, which will be mined in parallel with the Garibaldi pit.

Garibaldi pit is proposed to be mined five months prior to plant commissioning with the mine waste to be used for TSF2 construction. The Clarks Gully pit will be mined upon completion of mining at Garibaldi.

The open-pit mining fleet will consist of an excavator, dump truck, dozer, grader, water cart, etc.

Underground mining

Underground mining operations at Metz, Garibaldi, Clarks Gully and Brackins Spur will utilise a modified Avoca technique alongside traditional methods of drilling, blasting, loading, hauling, and backfilling.

The underground mining fleet will consist of a development jumbo, production drill, loader, trucks, etc.

Underground access and haulage for Metz will be via an existing portal in Metz Gully while a new portal will be established at the Garibaldi open pit for Garibaldi. Clarks Gully will also be accessed via a new portal from the Clarks Gully open pit.

Brackins Spur will be accessed from an existing portal and Brackins Spur Haul Road initially, Subsequently, it would be shifted to Garibaldi decline, post the completion of the Garibaldi-Brackins link drive.

Ore processing

The run-of-mine material will be crushed in a primary jaw crusher followed by a secondary crushing circuit.

The milling process will undergo significant changes, including the conversion of the semi-autogenous grinding mill to an overflow ball mill. The cyclone cluster will be replaced to allow for an increased primary grind size to 180 microns.

Gravity gold will be recovered via a Knelson concentrator, feeding an Acacia Intensive Leach reactor, followed by electrowinning and smelting to produce dore on-site.

In the flotation and regrind stage, the Antimony Rougher Circuit will be duplicated using the existing Gold Rougher Cells, and a new 50m³ cell will be added as a Rougher Cell for the Gold Flotation Circuit.

The concentrate thickening and filtration systems for both gold and antimony will be upgraded. The gold room will have some minor improvements, a settling cone for the electrowinning circuit sludge washbox, and a new barring furnace.

The reagents system will be enhanced with new pumps and increased dosing rates to optimise chemical use. The flotation circuit will produce antimony and gold concentrates, which will be filtered and bagged for transport on-site.

Life of Mine recoveries to payable are estimated to be 83.1% for gold and 86.0% for antimony.

Site infrastructure

Hillgrove Mine is currently connected to a 66kV power line, which enters the site via a step-down transformer, from which HV power is distributed at 11kV. The 66kV supply is fed by the regional Essential Energy network that is connected to the national grid.

Contractors involved

Larvotto Resources and consultancy company AMC prepared a mineral resource estimate report. AMC also provided input for mine planning, and project evaluation.

Onward Consulting, a Houston-based consulting company, was responsible for the environmental baseline studies and assistance with project permitting.

OreTeck Mining Solutions, a mining consultancy, offered geotechnical services and mining planning and scheduling expertise.

Knight Piesold, an international engineering and environmental consulting company, was responsible for the tailing storage facilities.

Mincore, an engineering and project delivery company in the mining sector, provided services which included processing plant design, metallurgy, test work, and infrastructure development.

Independent Metallurgical Operations, Australia’s largest metallurgical consulting company also provided inputs in metallurgy and test work.