The Havieron project is a high-grade gold and copper deposit being developed in Paterson province, Western Australia.

Newcrest Mining (Newcrest) owns a 60% interest in the project while Greatland Gold holds the remaining 40%. Newcrest can increase its ownership to 70% and also has an option to acquire a further 5% to take its project interest to 75%.

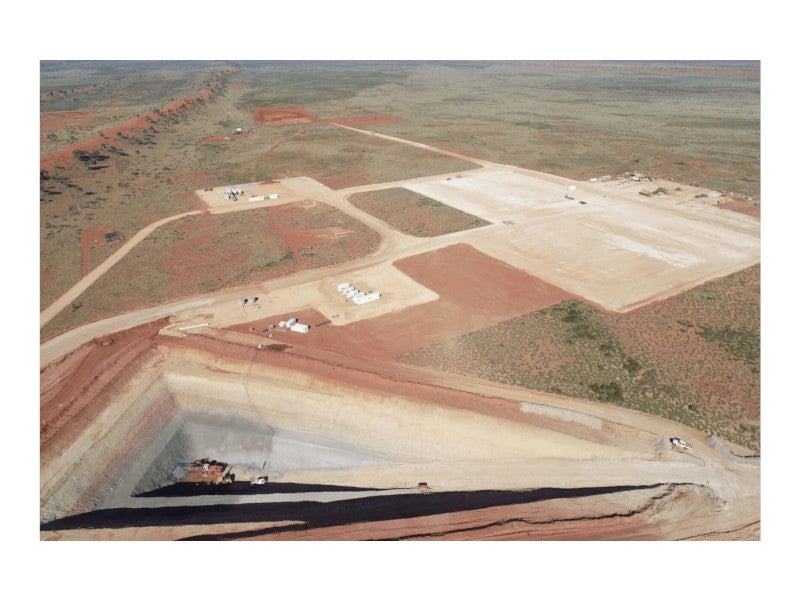

Construction of a box cut, an exploration decline, and associated surface infrastructure began in January 2021.

The feasibility study is expected to be completed in December 2022 while first ore is expected in the first half (H1) of 2024. Gold/copper production is expected to begin in the second half (H2) of 2024.

Location and geology of the Havieron project

The Havieron project is a gold-copper deposit located in the East Pilbara Shire of Western Australia. It is situated approximately 45km east of the Telfer gold mine, which is operated by Newcrest, and 450km east-southeast from Port Hedland.

The deposit is centred on a deep magnetic anomaly located within the northwestern exposure of the Palaeoproterozoic to Neoproterozoic Paterson Orogen.

The Havieron prospect is located within the Yeneena Supergroup, which comprises a 9km-thick sequence of marine sedimentary rocks.

Mineralisation and reserves of the gold-copper deposit

Mineralisation is found under 420m of post-mineralisation Permian cover in metasedimentary and intrusive rocks.

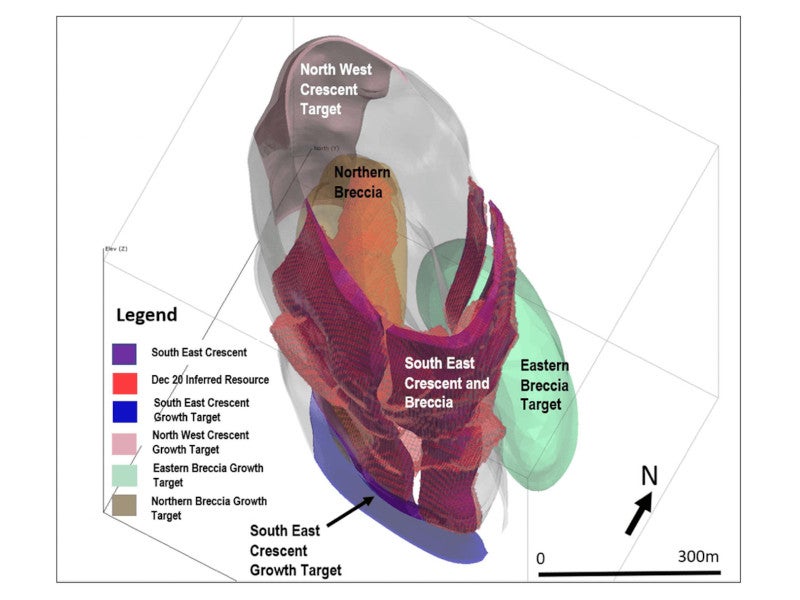

Gold and copper mineralisation is present in the form of breccia, vein, and massive sulphide replacement mineralisation.

The deposit contains pyrhotite-chalcopyrite and pyrite sulphide as the major mineral assemblages.

The probable reserves are estimated at 25 million tonnes (Mt), containing 2.4 million ounces (Moz) of gold and 109,000t of copper, grading 3g/t of gold and 0.44% copper, according to the revised estimates released in March 2022.

Mining at Havieron project

The Havieron project will employ the underground sub-level open stoping (SLOS) mining method with paste fill and truck ore haulage, according to the PFS. The mine will operate at an estimated rate of two million tonnes per annum (Mtpa) with an expected mine life of nine years.

The underground mining operation will target the Crescent Zone. The primary stopes will be mined first, followed by the intermediate secondary stopes. The mining operation will employ a top-down sequence, divided into multiple lifts separated by horizontal sill levels.

The design includes nine semi-independent mining sequences, based on horizontal and vertical mining fronts.

Processing ore from the Havieron deposit

The ore produced from the mine will be transported to the Telfer gold mine for processing under an ore tolling arrangement between the JV partners.

The processing infrastructure at the Telfer facility will be modified to accommodate ore from the Havieron project.

Havieron ore will be processed using a single train at the Telfer Train 2 Treatment Plant circuit on a campaign basis at the rate of approximately 2Mtpa.

The modifications to the processing plant will include magnetic separation within the flotation circuit to reduce the amount of pyrrhotite in the final copper concentrate. A carbon-in-pulp (CIP) circuit will also be added to the flotation tail and cyanide detoxification circuit.

Processing will involve traditional flotation methods. A flotation tails leach circuit to be installed at the processing plant will be used to produce copper/gold concentrate and dore.

Infrastructure details

A 55km-long haul road will be constructed to enable the movement of trucks to transport ore from the project to the Telfer processing facility.

Tailings will be stored at the existing tailings storage facility at the Telfer site. A waste rock dump, evaporation ponds, and supporting infrastructure such as offices and workshops will be constructed.

A 66kV overhead power line running parallel to the selected haul road route will transmit electricity from Telfer’s existing gas power station to the Havieron project site. The feasibility study will investigate other options to switch to power generation using non-fossil fuels.

A landfill is also proposed to be constructed to deposit non-mineralised waste.

Contractors involved

Australia-based Derisk Geomining Consultants was engaged to conduct an independent review of the project’s underground mineral resource estimate, which was released in November 2020.

Underground mining contractor Byrnecut was appointed to undertake works such as site establishment, box-cut support, decline development, shotcrete and raiseboring services.

Rockwater, a hydrogeological and environmental consulting firm based in Australia, received a contract to provide hydrogeological consultancy services for the project.

The contractual scope included packer and pumping tests, core logging, nuclear magnetic resonance surveys, and correlation with geotechnical datasets to characterise aquifers within the thick Permian overburden.