Greenhills is located in the Elk River coalfield, 8km from Elkford in southeastern British Columbia (BC). Fording purchased an 80% interest in the mine in 1992, the remaining 20% being owned by Pohang Steel Canada, a subsidiary of Pohang Iron and Steel of Korea. The mine was originally owned and operated by Westar Mining, which also worked the Balmer (later Elkview) operation near Sparwood, BC.

In 2003, Fording’s ownership stake in Coal Mountain was transferred to the Elk Valley Coal Partnership, now 60% owned by Fording Canadian Coal Trust and 40% by the major Canadian mining company, Teck Cominco. Elk Valley Coal is the world’s second-largest supplier of metallurgical coal, its sales in 2004 having been 22.6Mt.

Greenhills’ primary products are medium-volatile and standard metallurgical coal used to make coke for the international steel industry. The mine also produces and sells thermal coke for use by power utilities and associated industries. The mine has a production capacity of 5.1Mt/y while the preparation plant can handle 5.0Mt/y. Its actual output in 2006 was 4.2Mt, down from 5.0Mt in 2005 and 4.9Mt in 2004.

During their time in ownership, Fording and Pohang invested more than C$100m in capital and development to strengthen Greenhills’ competitiveness in the international marketplace.

Geology and reserves

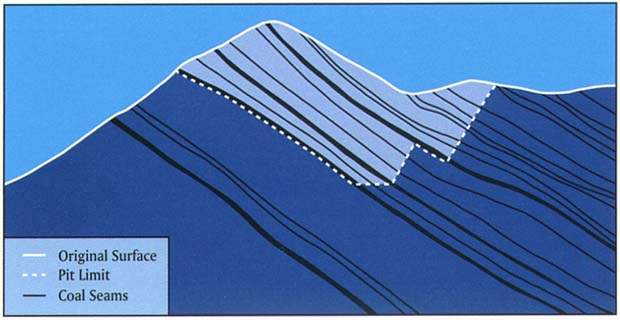

Greenhills lies within the Elk River coalfield, in which coal resources are hosted in rocks of the jurassic Kootenay formation. The strata have been extensively folded and faulted, a factor that has helped increase the apparent thickness of seams in some areas. Resources at Greenhills are generally of low- and mid-volatile bituminous rank, with low sulphur contents.

As of end-2006, the mine’s reserves consisted of 96Mt of clean coal in 13 different seams, plus a further 304Mt of measured and indicated resources. Of this total, 90% of the reserves are contained within the Cougar North, South, Main and Raven pits of the Greenhills range. The seams that are currently being mined range in thickness from 1m to 10m.

Other areas of the Greenhills property contain reserves in 15 recoverable coal seams. These areas are scheduled for mining at a future date.

Open-pit mining

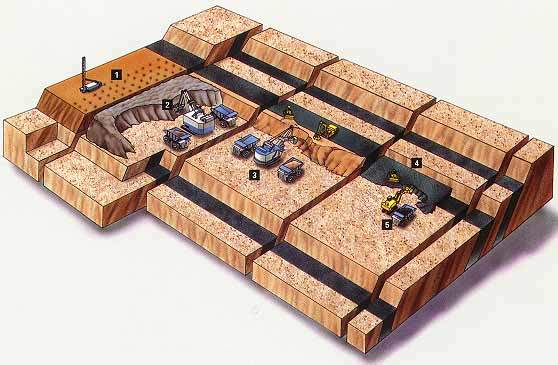

Greenhills operates as a conventional open-pit mine, using sequential development of 15m-high benches from the upper levels downwards through coal-bearing strata. Overburden, coal and inter burden are removed in sequence.

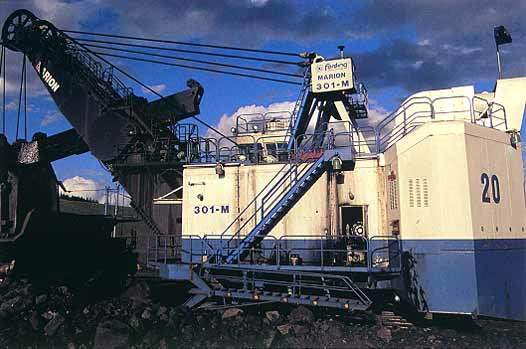

The mine has a fleet of five electric mining shovels, the largest of which are a Marion 301-M and a P&H 4100XPB, both with a 44m³-capacity bucket. Three P&H 2800s with 36m³ and 20m³ buckets complete the loading fleet.

Other mining equipment includes a LeTourneau L1850, 34m³ hydraulic shovel, two Caterpillar 994 wheel loaders for coal handling in the pits, Komatsu 830E 218t-capacity rear-dump haulers for overburden and 155t-capacity coal haulers. Bulldozers are used for cleaning the coal seam surfaces and for pushing coal towards the loaders in the pit. Many of the haulers were retrofitted with more powerful (2,500hp) engines during the early 2000s.

Global positioning system (GPS)

In late 1994, Greenhills introduced a computerised dispatch system to optimise the productivities of its large-scale mining equipment. This system incorporates real-time satellite technology to monitor and dispatch trucks to the shovels and loaders, ensuring that the mining fleet is used in the most productive manner.

This was upgraded in 1995 with the conversion of the conventional optical survey system to a high-resolution GPS system. An Aquila Mining GPS-based grade control system was initially tested on the largest shovel and was later retrofitted to the remaining mining shovels.

The system allows the mine to track and relay technical information to the production, maintenance and engineering departments on a regular basis. This ensures that all departments have an accurate and real-time record of the current mining configuration, which is used in planning future mining activities.

Coal processing

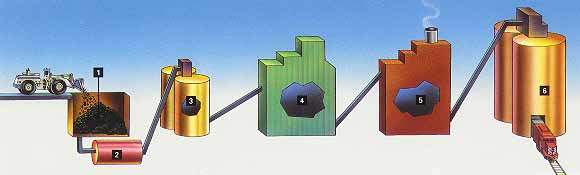

Run-of-mine coal is crushed, screened and washed to produce the required coal qualities for Greenhills’ customers. The washery uses dense-medium cyclones, spirals and flotation to clean the coal, which is dried before shipment by rail to the Westshore Terminals export facility at Roberts Bank, south of Vancouver.

Development

To date, the Cougar North reserve area has formed the basis for Greenhills’ production. Elk Valley Coal and Pohang are now developing Cougar South, where the reserves are sufficient to support mining at current rates for at least 23 years.