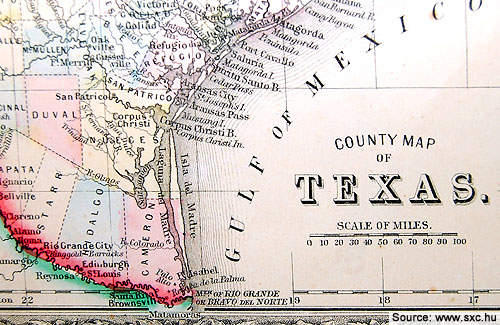

The Goliad uranium project is located in north-central Goliad County in the south of Texas. The project comprises 13 uranium mining leases spanning over 1,421 acres. The project is owned by Uranium Energy and is among the company’s four in-situ recovery (ISR) uranium projects in south Texas.

The project has obtained most of the permits including the mine permit, the Area Authorization for Production Area One (PA-1) and designation of an Exempt Aquifer from the commissioners of the Texas Commission on Environmental Quality (TCEQ). TCEQ is the regulatory body for in-situ mining and uranium processing plants in Texas. The Radioactive Material License (RML) was issued by TCEQ in December 2011.

Aquifer Exemption concurrence for the Goliad project, the final authorisation for commencing uranium extraction, was issued in December 2012.

The processing equipment, ion exchange (IX) vessels, and the material required for constructing the IX pipe and valve system were delivered in November 2013. Production is expected to begin in 2014.

Uranium Energy received a $20m credit financing from Sprott Resource Lending Partnership and CEF (Capital Markets) in July 2013. The credit facility is being used to meet the working capital requirements and also to develop and operate the Hobson, Goliad and Palangana projects.

Reserves and resources

The mine contains 6.9Mlbs of Triuranium Octoxide (U3O8). Measured and indicated resources amount to 5.4Mlbs while inferred resources total 1.5Mlbs.

Geology and mineralisation

The deposit lies within the Interior Coastal Plains section of the Gulf Coastal Plains physiographic province. Tertiary aged sedimentary units dominate the geology of the region. The sedimentary units, that are predominantly continental clastic deposits, dip and thicken towards the Gulf of Mexico.

The property occupies the outcrop area of the Goliad Formation that extends from surface until a depth of about 500ft. Uranium mineralisation remains open laterally and occurs between 90ft and 450ft of depths within sand-sandstone type tabular and rolls front deposits in four vertically arranged sand horizons.

The sand horizons are designated from younger (upper) to older (lower) from A through D respectively. The average thickness and grade of all sand horizons are 14.5ft and 0.075% respectively.

The sand deposits are between 1ft and 45ft thick and of the fluvial-deltaic origin. They are arranged in a C-shaped convex configuration in a downdip direction. Medium to finely grained sands are hosted with silt and different quantities of secondary calcite. Silty clay or clayey silts separate the sand deposits hydrologically by 10ft to 50ft.

At depths between 30ft and 60ft, groundwater permeates into the sands. Due to the presence of strong reductants in permeable sands, widespread or localised zones of reducing groundwater conditions are created. This results in migrating dissolved uranium in oxidizing groundwater to precipitate and concentrate. Due to the strong geochemical reduction, unoxidised sediments dominate the uranium bearing sand intervals.

The mineralised zones within the project area are cut and offset by two normal faults. One fault downthrown is towards the north-west while the other is towards the coast. The throws range between 40ft to 80ft.

Goliad mining

Mining at the Goliad project is by the ISR method. This is the most suitable method due to the grade and size of the deposits in the sands hosted underneath the water table and at depths where open pit and underground methods become unfeasible.

The minerals will be recovered from the host rock by employing chemical based indirect methods without removing the rock. In the ISR method, uranium from the deep ore is dissolved and brought to the surface. Uranium is dissolved by injecting a leaching solution into the ground through injection wells. The injection wells are arranged to effectively recover the uranium.

The leaching solution, which is generally composed of oxygen and bicarbonate supplemented groundwater, flows across the uranium hosting zone and dissolves it.

The dissolved uranium is pumped to the surface through production wells. This solution is then processed at the surface to separate the uranium.

The ISR method reverses the natural process through which uranium deposits are formed. Compared to conventional open-pit mining, it causes fewer disturbances to the ground. It, however, results in contamination of the groundwater surrounding the ore.