The Fungoni project is an open-pit heavy mineral sands (HMS) project located approximately 25km to the south of Dar es Salaam port, Tanzania.

Strandline is developing the project through its fully owned subsidiary, Jacana Resources. The mine is expected to produce saleable titanium and zircon mineral sand products.

Environmental approval for the heavy mineral sands project was granted in July 2017, and the definitive feasibility study (DFS) was completed in October 2017. The project is currently in the advanced exploration stage and Strandline is working on securing mining licence, land access approvals and project funding.

Being developed as a low capital cost fit-for-market operating model, the project is expected to be commissioned within 12 months. It is estimated to produce two million ton (Mt) a year through its initial life of mine (LOM) of 6.2 years.

It is expected to produce 302.3kt of saleable heavy mineral sands including 197.1kt of ilmenite, 15.6kt of rutile, 82.5kt of zircon and 7.1kt of monazite.

Fungoni project geology and mineralisation

Tanzania hosts two main types of heavy mineral placer style deposits including thin but high-grade strandlines, in addition to large but lower grade deposits related to windblown sands.

The surface geology of the project tenement hosts grey to white sandy soils within and overlying a thicker mixed sedimentary sequence.

Most of the mineral resources at Fungoni are hosted within a bow-shaped depression at the base of a 10m rise to the west. The mineralisation extends further up and over the topographic rise towards the north-west region, where more heavy mineral sand has been identified.

The orebody is exposed at surface and the high-grade mineralisation shows a very strong geological continuity along strike and at depth. The higher grade upper domains are categorised by more dominant minerals such as zircon, ilmenite and rutile, as well as kyanite and sillimanite.

Fungoni HMS project reserves

The Fungoni heavy mineral sands project is estimated to hold maiden ore reserve of 12.3Mt containing 480,000t of total heavy mineral (THM) grading 3.9%.

Mining and ore processing at Fungoni

Conventional open-pit dry mining will be applied at Fungoni, wherein the free-dig unconsolidated sand will be mined using an excavator. Ore will be hauled by truck up to 750m and fed to a mobile feed unit (MFU).

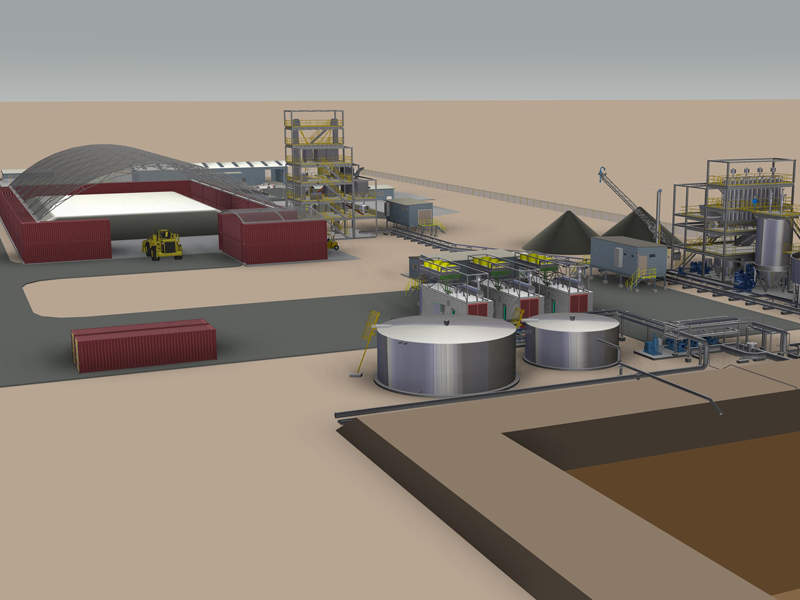

The process and non-process infrastructure will be constructed entirely on a modular relocatable design, which facilitates simple construction and de-commissioning. Advanced beneficiation and mineral separation techniques will be implemented at the plant to treat ore and produce three separate products, namely ilmenite, rutile, and a combined zircon-monazite product.

The project will include three on-site processing facilities including the MFU, a wet concentration plant (WCP) and a mineral separation plant (MSP).

Ore from the run-of-mine (ROM) pad will be delivered to the MFU for scrubbing and coarse screening in a trommel. The resultant sand/clay mixture will then be directed to the WCP for further screening and de-sliming.

The WCP will separate the coarse material and clays from the ore by using multiple screens and cyclones. The heavy mineral from the resultant sand will be separated by spirals and classifier technology. The resultant HM concentrate will be processed in the MSP to produce saleable rutile, ilmenite and zircon-monazite products.

The final products will be packed in containers in bulk form and transported to the Dar es Salaam port by trucks just-in-time.

Offtake of products from Fungoni

Chinese mineral sands processing company Hainan Wensheng High-Tech Materials has agreed to purchase the entire zircon-monazite produced at the Fungoni project under a binding offtake agreement. The company has agreed to purchase the zircon-monazite products throughout the project’s LoM.

Strandline also entered an agreement with Maoming Ubridge Group Mineral Industry for the sale of ilmenite produced at Fungoni in May 2018. The agreement includes the purchase of ilmenite throughout the LoM.

Infrastructure at Fungoni

An on-site diesel-fired power plant will provide the power required for the project. Operational water will be collected from in-pit, while storage water will be sourced from tailings and slimes dams, and raw water will be supplied from a local bore field.

Other major mine infrastructure to be constructed include site roads, water treatment plant, ablution facilities, tailings storage facility, workshop, and other buildings and offices.

Financing for Fungoni HMS project

Strandline Resources raised $5.2m from institutional and sophisticated investors in two tranches, under a strategic placement, for funding the DFS of the Fungoni project.

The placement includes the issue of approximately 651 million shares, of which Tembo Capital acquired 209.9 million shares in July 2017 under the second tranche to gain a 32.2% stake in Strandline.

Contractors involved

GR Engineering Services designed the infrastructure facilities as well as prepared the overall capital and operating cost estimates for the Fungoni project as part of the DFS.

IHC Robbins (IHC) provided geology and mineral resource estimates, while AMC Consultants conducted the mine study and estimated the ore reserves.

Knight Piésold (KP) conducted the hydrology, hydrogeology, tailings storage and geotechnical studies, while TZ Minerals International (TZMI) conducted the product marketing and commodity price forecast studies.

Other parties involved in preparing the DFS were Allied Mineral Laboratories, Environmental Resource Consultants, and Kiv Five Consultants.

UK-based financial advisory firm Argonaut Capital is providing financial assessment and strategic planning services to Strandline with regards to the Fungoni project.