The Eau Claire project is a gold deposit located in Québec, Canada. It is 100% owned by precious metals exploration company Eastmain Resources.

The project is expected to produce 6.4 million tonnes (Mt) of mineralised material that will be processed at the rate of 1,500 tonnes per day (tpd) over a period of 11.8 years.

Eau Claire project development

SEREM Québec and Société de développement de la Baie-James (SDBJ) began exploration works with airborne electromagnetic surveys and limited core drilling at the location in the early 1970s.

Eastmain and Westmin Resources undertook a comprehensive exploration programme between 1984 and 1989, leading to the discovery of a number of gold-bearing quartz-tourmaline veins.

Eastmain exercised the option to increase its ownership of the property to 100% in 2004. It completed multi-stage exploration programmes such as high definition airborne and ground geophysical surveys, soil geochemical sampling, and extensive core drilling until 2017.

The company is undertaking approximately 4,000m of drilling, targeting the lateral extension of the high-grade schist vein system.

Auryn Resources will acquire all the shares of Eastmain as part of an agreement signed by the companies in July 2020. The acquisition will result in the creation of Fury Gold Mines, which will begin a 50,000m drill programme following the completion of the deal.

Auryn and Eastmain completed an equity financing of C$23m ($17.23m) to support the expansion of Eau Claire and the exploration of other targets in Quebec.

Eau Claire project location

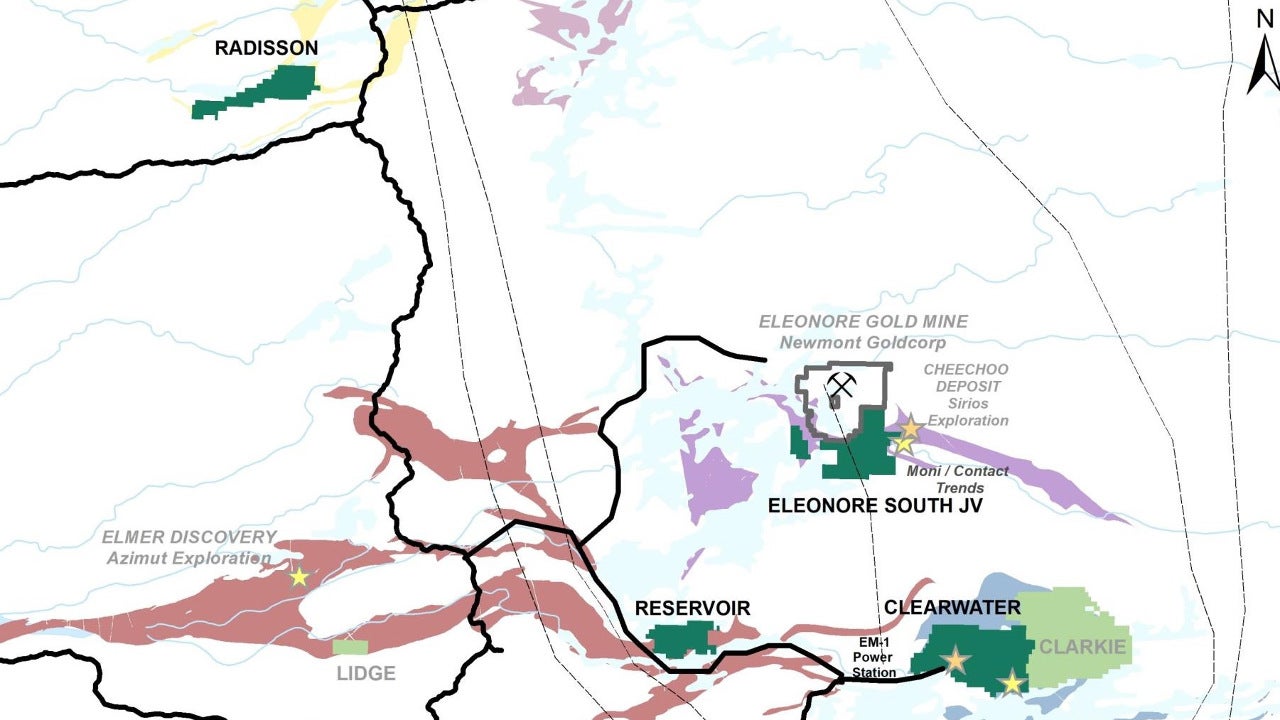

The Eau Claire gold project is located approximately 350km north-west of the town of Chibougamau in central Québec and approximately 800km north of Montréal.

The deposit and the enclosing area form Eastmain’s Clearwater property, which is accessible from a commercial airport in Nemiscau and Hydro Québec’s nearest service road.

Geology and mineralisation

The Clearwater property is characterised by Archean greenstone belt assemblages of the La Grande Group, majorly composed of volcanic rocks of basaltic to rhyolitic composition and of clastic and chemical sedimentary rocks.

Metamorphism includes upper greenschist to amphibolite facies in the greenstone aggregation while higher-grade facies characterise the Opinaca sub-province.

The structurally-controlled gold deposit includes en-echelon sheeted quartz-tourmaline veins and altered rock coinciding with a mafic volcanic/felsic volcaniclastic contact, along the southern limb of an F2 anticlinal fold. The gold-bearing quartz-tourmaline veins and alteration zones are located sub-parallel to the F2 fold axis and related to a D2 structural event.

At Eau Claire, more than 90% of the gold-mineralisation is present in iron and magnesium-rich tholeiitic basalts.

Resources of Eau Claire gold deposit

The gold mine has 4.29Mt of measured and indicated resources graded at 6.18g/t of gold (Au) containing 853,000oz of Au, as of February 2018. It is estimated to hold 2.38Mt of inferred mineral resource graded at 6.53g/t of Au for 500,000oz of gold.

Mining at Eau Claire project

The Eau Claire deposit comprises narrow and steeply dipping mineralised zones, making it suitable for both conventional open-pit and underground mining methods.

The project mine plan includes the development of two open pits, along with an underground mining operation underneath the open pits. Open-pit mining will commence first, followed by underground mining works.

The 850 West open pit will have a maximum depth of approximately 30m while the 450 West open pit will have a maximum depth of 100m from crests at the surface to the pit bottom.

Mining works will be undertaken on a retreat basis, beginning from the furthest lateral extent of a level towards the access ramp intersection, excluding the parts where a number of parallel veins are found and provide multiple working faces in a localised area.

The project plans to mine approximately 1Mt of waste material during a pre-strip phase of six months, followed by mining of 7Mt of mineralised and waste material every year for more than two years of production.

The mining fleet for open-pit mining will include 55t trucks, a 7m³ hydraulic excavator, and a 7m³ wheel loader.

The underground part will be accessed via a portal and decline ramp from the surface, with accessibility to all the levels through various internal ramps. Most of the stopes in the deposit are planned to be mined using a captive sub-level long-hole method due to the inconsistent dip and thickness of the veins, while some areas will involve standard level-to-level long-hole operations.

The stripped overburden will be stockpiled in an overburden storage facility until needed for reclamation and closure.

Backfill is planned to be run-of-mine rock fill with some sections requiring cemented rock fill for the removal of in-situ pillars. The cemented backfill will include either 4% (for adjacent mining) or 8% (for undercut mining) cement by mass and utilise sub-100mm aggregate. It will be transported from the surface to a re-muck bay near the filling location, before being sent to the filling stope via a load-haul-dump unit.

Processing at Eau Claire project

The run of mine mineralised material will first undergo crushing in a jaw crusher, followed by grinding to a grind size (K80) of 48 microns in a semi-autogenous grinding (SAG) mill and a ball mill in closed circuit with hydrocyclones.

A significant amount of available free gold will be removed from the cyclone underflow slurry using a gravity gold recovery circuit and subsequently processed in a batch reactor. The recovered gold-bearing solution will then be sent to the leach circuit. The leach discharge will travel via a series of carbon columns, including a carbon-in-pulp (CIP) circuit, which will adsorb the gold onto active carbon.

Carbon will go through the columns counter-current to the leach slurry and then report to the gold elution circuit, where the gold will be eluted in a high-temperature pressure vessel. Elution will be followed by electrowinning and smelting to produce gold dorés.

Infrastructure details

The mine site will receive power from the Hydro Québec power dam via a dedicated 18km transmission line.

The water from the tailings facility as well as the open-pit mine and underground mine will be collected and sent to a central water reservoir for treatment. Groundwater will be collected from a pristine surface water source or a well at the site and will undergo treatment in a containerised potable water treatment plant. Domestic sewage will also be collected and treated before being sent to the central water reservoir for use at the plant.

Other infrastructure will include explosives storage magazines, an accommodation camp, an office, assay lab, maintenance shop, warehouse, underground ventilation buildings, and storage tanks for water and fuel.

Contractors involved

SGS Canada (SGS) prepared the updated mineral resource estimate while P&E Mining Consultants (P&E) completed a technical report for the preliminary economic assessment and revised resource estimate.