The Clayton Valley lithium project is an open-pit mine being developed in Nevada, US, by Cypress Development, a Canada-based lithium (Li) exploration company.

A pre-feasibility study (PFS) for the lithium project was completed in August 2020, which was updated in March 2021. It estimates a 40-year mine life and a capital investment of $493m. The project has the potential to become one of the biggest lithium mines in the US.

Cypress Development began the development of a lithium extraction pilot plant for the Clayton Valley lithium project at the del Sol Refining & extraction facility, south of Beatty, Nevada, in March 2021. A chloride-based approach is being used for the initial configuration of the pilot plant.

The company signed a share purchase and licence agreement with Chemionex, a hydrometallurgical process development company based in Canada, in July 2021 to license its proprietary technology for the direct lithium extraction (DLE) section of the project’s processing plant.

Clayton Valley lithium project location and geology

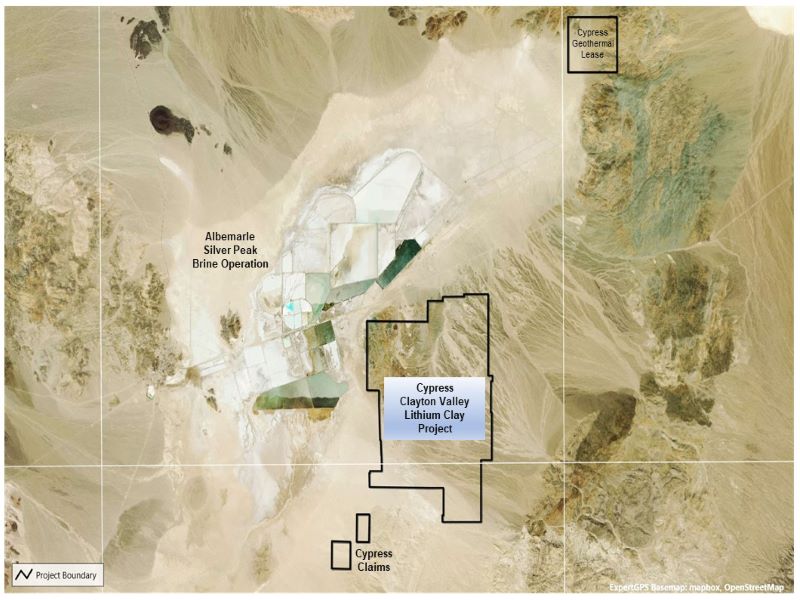

The Clayton Valley lithium project is located in central Esmeralda County, immediately east of Albemarle’s Silver Peak mine that has been in operation since 1966 and is the only lithium-producing operation in North America.

It also adjoins the 23,300-acre Clayton Valley lithium brine project being developed by Canadian mineral exploration firm Pure Energy Minerals. Cypress’ project area encompasses 129 unpatented placer mining claims and 212 unpatented lode mining claims spanning approximately 5,430 acres.

The deposits of Clayton Valley are hosted by a closed basin located near the south-western margin of a vast physiographic region in western Nevada, known as the Basin and Range province. The uplifted basement rocks of Angel Island comprising metavolcanic and clastic rocks, and colluvium dominate the western part of the project area.

The southern and eastern portions of the project area, on the other hand, mainly comprise uplifted, lacustrine sedimentary units of the Esmeralda formation that features fine-grained sedimentary and tuffaceous units.

Mineralisation and reserves for Clayton Valley

The mineralisation at the Clayton Valley lithium project is found as elevated lithium concentrations above 600 parts per million (ppm) in the Esmeralda formation. It extends up to 142m below the surface. The silica-rich, lithium-bearing sediments in the project area contain moderately calcareous, interbedded tuffaceous mudstones, siltstones, and claystones. The primary mineralised zone is hosted by a claystone unit that comprises the oxidised and unaltered claystone zones.

The project is estimated to host probable mineral reserves of 213 million tonnes (Mt) containing 1.28Mt of lithium carbonate equivalent (LCE) graded at 1,129ppm of lithium (Li). Indicated mineral resources are estimated at 1,304Mt, grading 905ppm Li at a cut-off grade of 400ppm Li.

Mining at Clayton Valley lithium project

The project will utilise conventional open-pit mining methods to extract lithium using a Caterpillar 6020B or equivalent hydraulic mining shovel with a 12m³ bucket capacity. The mining operation is not expected to involve drilling and blasting due to the soft nature of the material.

The mine design includes 16 pit phases within the ultimate pit shell, of which only the first 11 were selected for the production schedule. The project will employ CAT 657G or equivalent scrapers with a 166tph capacity to remove the overburden and waste material in each mining phase.

Each of the pit phase benches will be split into 10m-wide longitudinal sections with the bench height and width of 7.5m and 6m, respectively. Portable jump conveyors, approximately 30.5m-long, will be placed at each end of the pit phase to transport the excavated ore to the mid-line of the pit phase.

Mineral processing of the Clayton Valley lithium project

The lithium project is expected to have a nominal production rate of 15,000 tonnes per day (tpd) to produce 27,400 tonnes per annum (tpa) of LCE over the mine life.

The ore from the mine will be fed into a mobile feeder/breaker to reduce the size to 125mm and conveyed to the run-of-mine (ROM) stockpile bins at the processing site. The ROM ore will be fed into a set of four stainless-steel rotary attritors to disaggregate the clay and reclaim water. The slurry from the attritors will be further mixed with water in slurry feed tanks.

The non-acidified slurry from each attritor will be passed through a screen to remove oversized material. It will then be fed into one of four leach trains and mixed with sulphuric acid. The slurry discharge from the leach tanks will be conditioned, filtered, and drained of pregnant leach solution (PLS) before being water-washed and drained once again.

The PLS will be transferred to storage tanks at the lithium recovery plant where it will be fed to equipment operating under a NORAM-CMS-designed arrangement for the removal of calcium, magnesium, and other elements to produce a concentrated lithium sulphate solution.

The solution will undergo electrolytic conversion and crystallisation to produce a lithium hydroxide solution. The final product will be washed, dried and packaged for shipping.

Infrastructure at Cypress’ Clayton Valley lithium project

The project site is accessible from Tonopah, Nevada, by a 35.4km-long stretch of the US Highway 95 and a 30.5km-long Silver Peak gravel road.

The steam generated from an on-site sulphuric acid plant will be used to produce approximately 27.5MW of electricity to meet the power needs of the project. The secondary power supply will be provided by a connection to the regional grid. One of the two 69kV transmission lines serving Clayton Valley runs just north of the project.

The project is estimated to require 30,283l of water a minute to meet its processing requirements. Approximately 75% of the water in the processing plant will be recycled and returned to the leaching circuit for reuse. A tailings storage facility will be located to the south of the plant site while other infrastructure will include an administration building, warehouse, reagent storage, and a mine shop.

Contractors involved

Cypress Development selected Ausenco Engineering Canada to serve as the consultant for the PFS of the Clayton Valley lithium project. US-based mining consultancy Global Resource Engineering (GRE) is the consultant for the project’s metallurgy, resource estimation, and mine planning.

American minerals consultancy Continental Metallurgical Services (CMS) and GRE jointly prepared the PFS for the project.

CMS and Canadian engineering services company NORAM Engineering and Constructors were engaged to develop the process flowsheet to efficiently concentrate the lithium.

US-based lithium extraction company Lilac Solutions was selected to test its proprietary lithium IX resin for ion exchange testing.