The Curipamba project is an open-pit copper-gold mining operation proposed to be developed in central Ecuador by a joint venture (JV) between Adventus Mining and Salazar Resources.

A feasibility study for the project was announced in October 2021. The results highlighted a life of mine of ten years and 1.5 years of pre-production with an initial capital investment of $248m.

An updated preliminary economic assessment on the underground development following the completion of the ten-year open-pit mine plan was also released along with the feasibility study.

Completed in November 2021, the environmental and social impact assessment (ESIA) for the project is yet to receive approval from the government.

Adventus Mining and Salazar Resources executed a shareholders’ agreement to form the JV for the development of the copper-gold project in January 2022. It holds a 75% stake in the Curipamba project while Salazar Resources owns the remaining interest.

Curipamba project location and geology

The Curipamba project is located approximately 150km north-east of Guayaquil in the provinces of Bolívar and Los Rios in central Ecuador.

It lies in central equatorial Andes, within the Macuchi Terrane magmatic island arc of Paleocene-Eocene age, adjacent to the Amazonian Craton.

The local geology is characterised by the Middle Paleocene-Eocene age submarine volcanic and volcaniclastic rocks of the Macuchi Group, overlain by Late Tertiary to Holocene volcanic rocks and Holocene alluvial deposits.

The project comprises seven concessions encompassing an area of approximately 21,500ha. One of the concessions is the advanced El Domo high-grade copper-gold deposit.

Mineralisation and reserves of the El Domo deposit

The gold-rich, polymetallic El Domo deposit is an intact, upright, and mildly disturbed Kuroko-type volcanogenic massive sulphide (VMS) deposit.

The largely flat-lying mineralisation occurs in a single, large stratabound sulphide lens and several smaller mineralised lenses located primarily in the footwall of the main lens.

The polymetallic sulphides contain sphalerite, chalcopyrite and pyrite as the principal sulphide minerals.

The proven and probable mineral reserves of the Curipamba project were estimated at 6.47 million tonnes (Mt) grading 2.52g/t gold (Au), 1.93% copper (Cu), 45.69g/t silver (Ag), 0.25% lead (Pb) and 2.49% zinc (Zn) as of October 2021.

Mining at Curipamba project

The Curipamba project will be developed as a conventional open-pit mining operation, which will involve haul trucks, hydraulic excavators, and loaders.

The pit is envisaged to be mined in five phases based on ore type over the mine life. Hydraulic excavators with a maximum bucket capacity of 3.3m³ will be used to load the waste rock in 10m benches. The ore will be mined in 5m benches and loaded using front-end loaders with a 3.9m³ capacity.

A total of 61.82Mt of ore will be mined from the open pit. The different ore types comprising high Zn, mixed Zn/Cu, and high Cu will be stockpiled separately to enable easy blending.

The overburden and saprolite will be sent to their respective stockpiles while other waste material will be divided to stabilise these stockpiles or to build the tailings storage facility. Additional waste material will be stored in the waste storage facility.

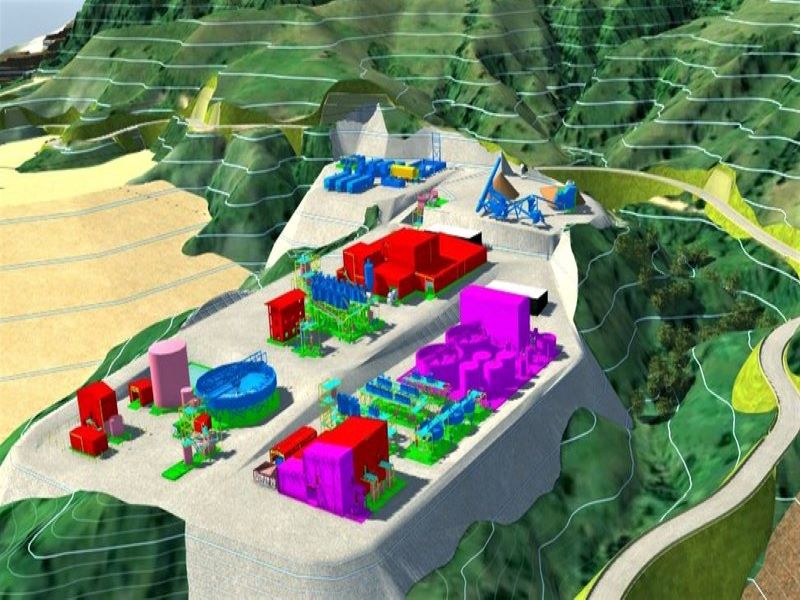

Ore processing at Curipamba project

The concentrator to be built for the Curipamba project is designed to process 666,000 tonnes per annum (tpa) of ore to produce copper, lead, and zinc concentrates. The project is expected to have an average production rate of 10,463tpa of copper and 21,390tpa of copper-equivalent products.

The run-of-mine (ROM) ore will be crushed in a primary jaw crusher and a secondary cone crusher. The crushed ore will then undergo grinding in a ball mill operating in a closed circuit with a cluster of hydrocyclones.

The cyclone overflow will be gravity-fed to the bulk flotation conditioning tank and then sent to bulk rougher flotation cells. The concentrate produced from the first cells of the bulk rougher flotation circuit will feed the copper flotation circuit. The bulk flotation concentrate will be pumped to a scalping cyclone cluster. The cyclone overflow material will be mixed with bulk regrind mill discharge and sent to the copper rougher flotation.

The first cleaner scavenger concentrate will be sent to the copper second cleaner and the resulting concentrate will be directed to the lead cleaners. A reverse flotation process will be used to produce the final copper concentrate.

The lead cleaning process will involve three stages and the final product will be manufactured at the end of the third stage. The resulting copper and lead concentrates are thickened and pressure-filtered in their respective circuits.

The zinc flotation circuit feed will comprise copper rougher tailings and may also include a bulk scavenger concentrate from the last cells of the bulk circuit.

The conditioned slurry will be sent to the zinc rougher flotation circuit to produce a tailings stream, which will be transferred to the final tailings thickener. The zinc concentrate slurry will feed the zinc concentrate thickener with the thickener underflow planned to undergo pressure filtration to produce zinc concentrate filter cake.

The concentrates produced will be shipped to refiners via the Posorja deep-water port, which is located 85km south-west of Guayaquil.

Infrastructure of the Curipamba project

Adventus purchased a pre-fabricated accommodation camp with the capacity to accommodate 100 personnel in June 2021, as part of the early works preparation for the Curipamba project. The camp has sanitary facilities and is planned to be augmented with a canteen and catering facility.

Adventus submitted preliminary applications to the electric utility authorities to secure the power allocation from the national grid.

A suitable tie-in point, located 7km to the west of the project site, was identified. A 69kV overhead line to the site is proposed to be constructed, while the local grid power line will be upgraded.

Off-take agreements

A definitive agreement was signed with Wheaton Precious Metals International, a subsidiary of Wheaton Precious Metals, in January 2022.

Wheaton Precious Metals International agreed to provide $180.5m in funding, including an upfront cash consideration of $175.5m in exchange for the supply of gold produced from the Curipamba project.

The company will be able to purchase 50% of the payable gold production until a supply milestone of 150,000oz is reached, according to the streaming arrangement agreement. The purchase ceiling will drop to 33% of payable gold production for the life of mine, once the supply milestone is reached.

Furthermore, Wheaton Precious Metals International will receive 75% of the payable silver production until the delivery of 4.6 million ounces (Moz), which will then reduce to 50% for the life of mine.

Adventus Mining and Trafigura reached an agreement for an off-take financing arrangement for the project. Trafigura committed up to $55m under a five-year financing facility.

Trafigura will have off-take rights for certain concentrate products from the El Domo deposit over the life of mine, subject to the completion of definitive documentation and an inter-creditor agreement with Wheaton Precious Metals.

The financial commitment from Wheaton Precious Metals International and Trafigura will provide the funding required for the pre-construction and future construction works, once the decision for the construction is taken.

Contractors involved in Curipamba project

Engineering and consulting company DRA Americas led the feasibility study for the project.

The company was also selected to provide engineering and procurement services for the copper-gold project in February 2022. The contractual scope includes detailed engineering and long lead equipment procurement.

SLR Consulting Canada (SLR), a global environmental and advisory solutions provider, was responsible for the geology and mineral resources studies, as part of the feasibility study. It provided initial water balance predictions while Minnow Environmental was selected to conduct water quality studies.

AOC Ingenieria, a local civil engineering company, was appointed to provide the design and estimates for the public road upgrades and site access road. Local design firm Engywork was engaged for the detailed design of the overhead powerline to the project site.

Canada-based Exen Consulting Services prepared an initial independent market study for the planned sales of concentrates from the Curipamba project.

Klohn Crippen Berger was contracted to conduct studies related to tailings storage, waste facilities, and hydrogeology, while geochemistry studies were performed by pHase Geochemistry.

Global consulting firm Knight Piésold was appointed to conduct environmental and social studies.