Kaminak Gold’s wholly owned Coffee Gold Project is located approximately 130km south of Dawson City in Yukon Territory, Canada. The preliminary economic assessment (PEA) for the project was completed in June 2014, followed by the feasibility study in January 2016.

The construction works for the project are expected to start in mid-2018, following the completion of an environmental and socio-economic assessment as well as the grant of the mining and water licences. First production from the project is anticipated in late-2019.

The total investment to bring the project into production is estimated to be C$317.4m ($228m approximately). The mine is expected to have an initial production life of ten years.

Direct benefits from the Canadian gold project will include the generation of approximately $2bn in gross revenue to Yukon’s gross domestic product (GDP), approximately 480 jobs during the construction phase and 435 jobs during operations.

Coffee Gold Project geology

The project is located within the Yukon-Tanana Terrane (YTT), which consists of schists and gneisses that were deformed and metamorphosed in the late-Paleozoic era, intruded by a large granitic body of the late-Cretaceous. The metamorphic rocks and cretaceous granite are cut by intermediate to felsic dykes (dacite and andesite).

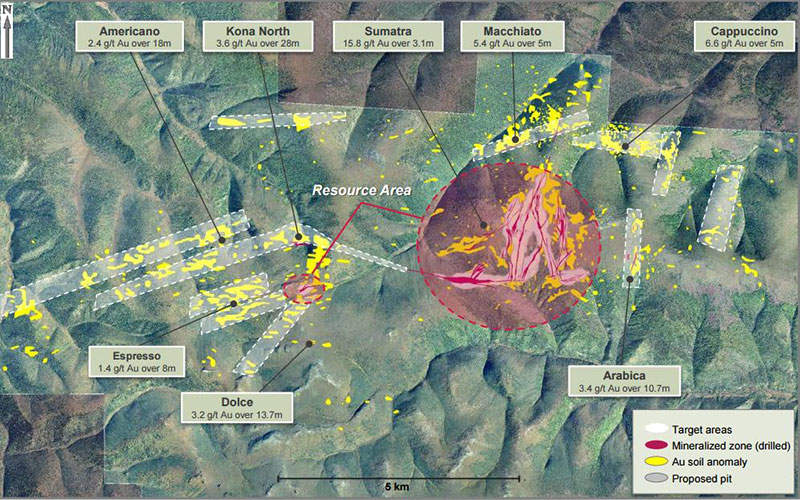

The gold mineralisation is primarily hosted either in breccia structures or dacite dykes with quartz, dolomite, sericite, and pyrite alteration. The mineralisation is hydrothermal in nature and is controlled both structurally and lithologically. Since the project’s discovery in 2010, 19 separate mineralised areas have been discovered through exploration drilling.

Reserves and production

As of September 2015, the project was estimated to hold indicated resources of 52.4 million tonnes (Mt) at an average grade of 1.68g/t Au, containing 2.82 million ounces (Moz) of gold, while resources in the inferred category are estimated to be 42.7Mt at a grade of 1.52g/t Au, containing 2.08Moz of gold.

The probable mineral reserves estimated for the project stand at 46.4Mt grading 1.45g/t Au, and containing 2.15Moz gold.

The average annual gold production from the project is estimated to be approximately 200,000oz for the first five years while the average annual life-of-mine gold production rate is estimated to be 184,000oz.

Mining and processing at Kaminak Gold’s flagship project

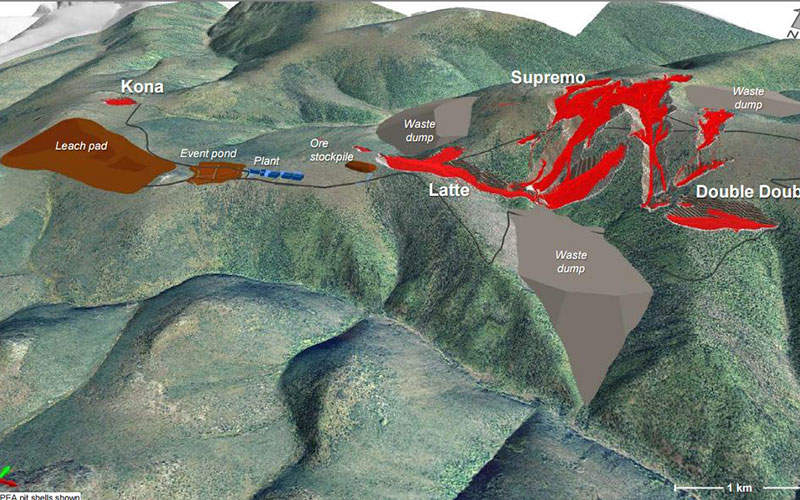

The project will involve the mining of the Supremo, Double Double, Latte, and Kona deposits using open-pit mining methods, integrating conventional shovel and truck operations. The nominal ore mining rate for the project is estimated at five million tonnes per annum (Mtpa).

The mining fleet will include 6m³ shovels, 12m³ front-end loaders, 4m³ excavators, and 144t haul trucks, complemented by drills, graders and dozers.

The processing plant envisaged for the project will incorporate a two-stage crushing circuit, a heap leach facility and an adsorption-desorption-recovery (ADR) carbon plant.

Infrastructure for the Yukon Territory gold mine

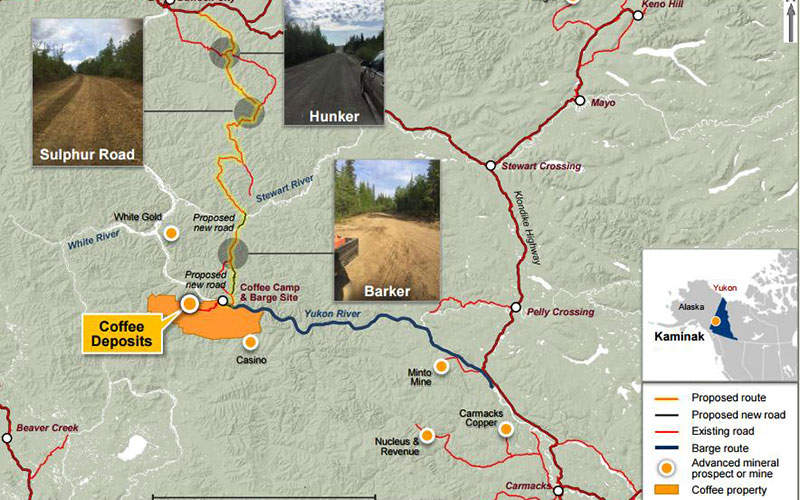

The project benefits from the presence of existing infrastructure including 23km of onsite access roads, a barge landing site and an airstrip.

The electrical power required for the project will be generated onsite by diesel / liquefied natural gas (LNG)-powered generators.

The project will utilise the groundwater to meet the process requirements, while water from the neighbouring creeks will also be used. Potable water will be conveyed by trucks from the neighbouring Yukon River.

Primary access to the project site will be via Dawson City through a 214km single-lane, gravel road that will be upgraded for a major portion, whereas approximately 37km will be newly constructed.

Other major new infrastructure for the project will include a 1,200m gravel airstrip, waste dumps, diesel storage tanks, explosives storage facilities, a sewage treatment plant, and buildings to house a truck workshop, a warehouse, offices, and accommodation facilities.

Key players involved with the Canadian gold project

The feasibility study was prepared by JDS Energy & Mining in collaboration with a number of consultants. SIM Geological performed the geological modelling and resource estimation, Kappes, Cassiday & Associates conducted the metallurgical test work, whereas ALS Canada conducted the crushing and abrasion test work.

SRK Consulting performed the geomechanical and geotechnical studies, as well as the water management study. The design study for the heap leach pad was performed by RRD International and The Mines Group.

The water balance, geochemistry and source terms studies were performed by Lorax Environmental Services, and the permafrost study was conducted by Tetra Tech EBA, while Onsite Engineering provided inputs on the access road.

The PEA was compiled by JDS Energy & Mining with assistance from Kappes Cassiday and Associates, Knight Piésold, and SIM Geological.