Cigar Lake is the world’s largest undeveloped uranium deposit. The mine is located in Saskatchewan, Canada. It is owned by Cameco Corporation (50.025%), Areva (37.1%), Idemitsu Canada Resources (7.875%) and TEPCO Resources (5%), and is operated by Cameco Corporation. Cigar Lake mine was expected to begin operations from 2007, but heavy water inflow in October 2006 delayed the start of operations.

The construction was resumed in 2011 and uranium mining finally commenced in March 2014 following receipt of operating licence from the Canadian Nuclear Safety Commission (CNSC) in July 2013. The operating licence is valid until June 2021. The mine produced 0.34Mlb (million pounds) of uranium concentrate in 2014.

Geology and mineralisation at the Canadian mine

The Cigar Lake deposit is located in the Athabasca basin and forms part of Manitou Falls Formation. The deposit is approximately 1,950m-long and 500m-deep below the surface. It is a flat lying deposit with sandstone lying upon the basement rock.

The deposit comprises three types of mineralisation, which include high-grade mineralisation or unconformity mineralisation, perched mineralisation and basement rock mineralisation.

High-grade mineralisation refers to the high-grade uranium contained zones in the deposit. Huge portions of quartz, clay and metallic minerals are also deposited in this region.

High-grade mineralisation was considered the viable zone of production in Cigar Lake, based on the mining method and ground conditions. Perched and basement rock mineralisations form a very small part of the total mineralised rock in terms of volume.

Reserves and exploration at Cigar Lake

Cigar Lake mine is estimated to have 537,100t of uranium reserves, including proven reserves of 233,600t and probable reserves of more than 303,500t of uranium.

Cigar Lake’s uranium deposits were discovered in 1981. The delineation activity was done from 1982 to 1986 and holes were drilled until 2002 for geotechnical studies. A total of 406 surface holes were drilled to delineate the deposit.

Diamond core drilling was also done at the mine from 1981. It was conducted in underground locations to determine the rock mass characteristics. A total of 222 holes were drilled from 1981 to 2011.

Mining methods used at the uranium mine

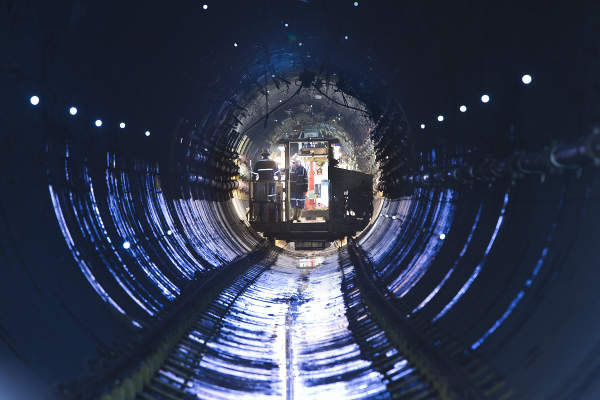

Cigar Lake is being mined using underground methods. The basement rock layer of Cigar Lake comprises two levels, 480m and 500m. Mining is conducted in the 480m level area, which is 25m below the ore zone. Underground processing and infrastructure facilities are located in this level.

The 500m level provides main ventilation exhaust drift for the mine and is accessed via a ramp from the 480m level.

A new mining method called jet bore system (JBS) is used in the mine. The method involves usage of high pressure water to cut cavities from the ore. It is a non-entry approach, where personnel will not get in direct contact with the orebody as all the mining will be down in the basement rock below the orebody. The mine will be equipped with four JBS mining units including two machines during full production and two for backfilling and maintenance.

The process involving JBS includes mixing of the ore with water to form slurry, which is pumped through pipes to the run-of-mine (ROM) ore receiving facility.

The ore slurry is transferred to the surface through a slurry pump. The slurry is stored and then transferred to McClean Lake JEB mill for processing.

Another innovative technique used at Cigar Lake mine is bulk freezing, which involves circulation of a brine solution through surface and underground freeze holes to prevent entry of water into the mine and stabilise the weak rock formations. Bulk freezing is expected to minimise the risk of water inflows to the mining site.

Processing uranium ore at Cigar Lake

The uranium ore is processed partly at Cigar Lake and partly at McClean Lake JEB mill, which is located 70km north of Cigar Lake. Ore size reduction is done at the underground region of Cigar Lake, while leaching, purification and final yellowcake production are done at McClean Lake JEB mill. Processing of Cigar Lake’s ore at the McClean Lake mill began by the end of the second quarter of 2014.

The ore slurry stored at Cigar Lake is transported to McClean Lake JEB mill through containers. The slurry is leached and treated in the McClean Lake mill tailings neutralisation area and ore tailings are generated. The tailings are thickened with vacuum and precipitated to form yellowcake.

The first uranium concentrate was produced from ore mined at McClean Lake in October 2014.

The McClean Lake mill employs more than 350 highly skilled workers. The mill is currently undergoing expansion, which is scheduled for completion in 2016.

Production and contractors involved

The mine is anticipated to produce 18Mlb of U3O8 a year during its expected lifespan of 15 years. The daily average production is estimated to be 140t.

Tron Power provided construction services for the Cigar Lake mine. The services included underground electrical construction and maintenance, jet boring pilot project piping and water treatment plant foundation. The contract for the planning, procurement, construction, fabrication and field construction of Cigar Lake mine was awarded to Canonbie.