The Chilalo graphite project will be developed as an open-pit mine. It is located within the Nachingwea property, a 5,400km² tenement area in south-east Tanzania.

The mine was previously operated by IMX Resources (Indiana Resources) and sold to Graphex Mining in June 2014.

Graphex Mining was renamed to Marvel Gold in August 2020. The project is now owned and operated by Evolution Energy Minerals (Evolution), a wholly owned subsidiary of Marvel Gold.

The pre-feasibility study (PFS) for the project was completed in September 2018. An updated definitive feasibility study was completed in March 2023.

The estimated life of the mine is 17 years with a preproduction capital estimated at $120m.

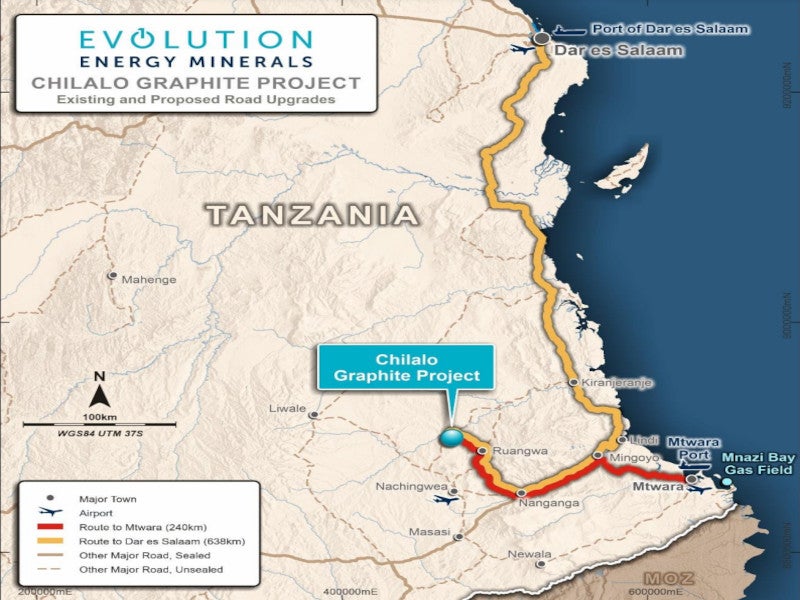

Project location

The Chilalo project is located in south-eastern Tanzania, East Africa, 100km north of the border with Mozambique and approximately 180km west of the coastal port city of Mtwara on the Indian Ocean.

It is 400km south of Tanzania’s largest city, Dar es Salaam and the property is situated in the Ruangwa District of the Lindi Region.

Geology and mineralisation

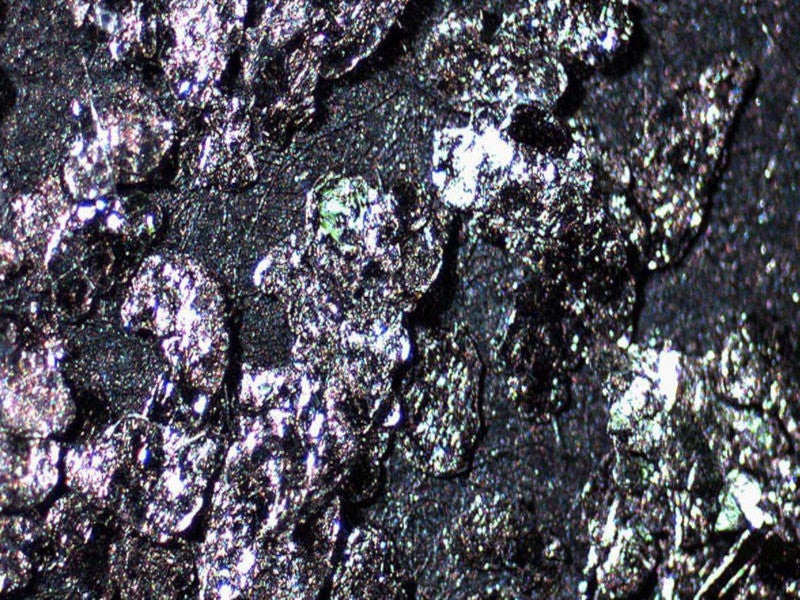

The mine is located within the renowned Mozambique belt, which hosts graphite deposits such as Syrah Resources’ Balama project and Magnis Resources’ Nachu project.

The project involves the development of the Shimba deposit.

Regional geology comprises late Proterozoic Mozambique mobile belt lithologies hosting mafic to felsic gneisses (aluminous rich sediments), which are interlayered with amphibolites (mafic-sourced material) and meta-sedimentary rocks.

Mineralisation is usually found within 100m of the surface, and primarily hosted in felsic gneiss and amphibolites and within high-purity marble horizons in rare quantities.

In early 2023, two new high-grade mineralised zones, Chilalo East and Chilalo E2, were discovered.

Chilalo East has high-grade mineralisation of more than 1.6km out of a potential 3.5km strike length indicated by an electromagnetic conductor.

Chilalo E2, located east of Chilalo mining licence and parallel to Chilalo East, has been tested for 1.1km out of a potential 5km strike with mineralisation open to the east and west.

Chilalo graphite project reserves

The project is estimated to contain a probable ore reserve of 8 megatonnes (Mt) grading 10.5% total graphitic carbon with a total contained graphite of 836,000 tonnes (t), as of March 2023.

Mining method

The Shimba deposit will be developed using open-pit mining methods integrating conventional 50t-60t rigid and articulated dump trucks, excavators and shovel operations.

The mining operations will be undertaken at three open pits – Central, North and West. The development schedule includes two stages for the West and North pits and four for the Central pit.

Mining operations will be carried out in benches with a height of 10m and 5.25m berms.

The Central pit will be 950m long, 350m wide, and 170m deep. The North Pit will be circular with a diameter of 300m and a depth of 122m.

Dual lane ramps of 17m wide will allow a safe passage for trucks while 12m wide single lane ramps will be used for mining last benches and goodbye cuts.

Cutback designs will maintain a minimum mining width of 30m while normal benches will maintain a mining width of 20m.

Ore processing at Chilalo graphite project

The Chilalo processing facility is designed to handle 500,000t a year.

The run-of-mine ore will undergo a two-stage crushing process, which involves the use of a primary jaw crusher followed by a secondary cone crusher.

The latter will be configured in a closed circuit with a double-deck vibrating screen.

Ore grinding and classification will be undertaken in a primary grinding mill comprising a rod mill operating in a closed circuit with a screen.

The undersize from the rod mill screen will be channelled to a flash flotation rougher cell while the oversize will be returned to the primary mill for reprocessing.

Graphite of a coarse nature will be harvested within the flotation circuit, whereas the rougher tailings will be directed to the ball mill cyclones.

Subsequently, the overflow from the secondary ball mill cyclone will be conveyed to the rougher scavenger circuit.

The resultant concentrates from both the rougher flash flotation and the rougher scavenger flotation will be transferred to the primary cleaner polishing mill feed tank.

The material will then undergo an extensive cleaning process, consisting of nine stages of cleaner flotation, four stages of polishing, and three stages of wet screening.

The cleaning process is designed to yield high-purity graphite concentrates of both coarse and fine varieties.

The final product will be subjected to a filtration process, followed by drying and classification into eight distinct bins, each corresponding to different grades.

The coarse and fine graphite concentrates will undergo separate filtration and drying processes, utilising an individual plate and frame filter, and a rotary drum dryer for each respective train.

Once dry, the graphite concentrate will be sorted into various product sizes using plansifter screens. The final products will then be packaged into bags, with the option of either 1t or 25kg capacities, ready for shipment.

Infrastructure for the Tanzanian graphite project

Power required for the project will be generated onsite by a 4MW power station integrating four 1MW diesel-powered gensets, one of which will serve as backup.

The process water for the project will be supplied from an on-site borewell.

Graphite concentrates from the project are to be transported to the Mtwara Port by trucks using an existing 220km road. Road sections adjacent to the project site will be upgraded.

At the Mtwara Port, the product will be stored in leased storage facilities and shipped to industrial customers, primarily in China.

Other major infrastructure for the project will include a tailings storage facility (TSF) and waste dumps.

The project benefits from existing infrastructure, including the Ntaka Hill camp with offices, mess hall, telecommunications, and laboratory facilities, located approximately 20km from the project site.

Funding

Graphex Mining secured $85m in funding from Castlelake in October 2018 for the project.

Offtake agreement

Evolution signed an offtake agreement with Yichang Xincheng Graphite, a graphite products manufacturer, for the sale of 30,000t per annum of coarse flake graphite from the project.

Contractors involved

The PFS was compiled by BatteryLimits, a mining project development consultancy, with inputs from consulting companies ATC Williams for the TSF and Knight Piesold for the water studies.

CSA Global, a mining consultancy business, determined the mineral resource estimates and geological studies while SGS Australia, a testing, inspection and certification company, was responsible for metallurgical test work.

Outotec, a technology provider to the minerals and metals processing sector, conducted the filtration test work.

Dhamana served as the advisor for Evolution offering expertise in project management as well as environmental and social aspects.

CPC Engineering, an engineering company, was awarded the front-end engineering design contract for the processing plant.

GR Engineering, a process engineering, design and construction company, was responsible for the process plant, engineering design, overall cost estimation and report compilation.

AQ2, a water management consultancy; Mine Waste Management, an environmental consultancy; and Azure Capital, an advisory company, were also involved in the Chilalo graphite project.