The Boardwalk lithium brine project is a proposed mining development in the west-central region of Alberta, Canada.

The project is wholly owned by the Canada-based LithiumBank Resources.

The preliminary economic assessment (PEA) was completed in February 2024, with an initial capital cost projection of $2.16bn for a productive lifespan of 20 years.

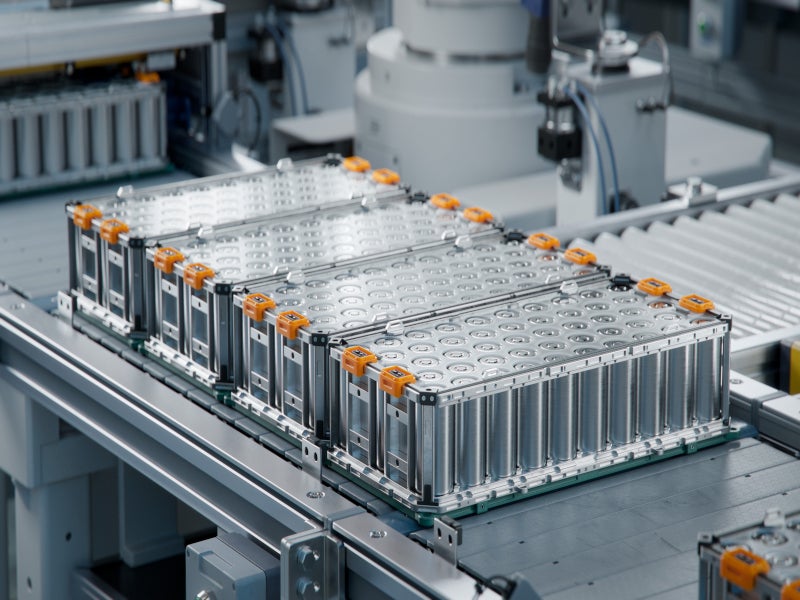

The project will boast a plant equipped with direct lithium extraction (DLE) technology to produce commercial-grade lithium hydroxide monohydrate, suitable for battery manufacture.

Boardwalk lithium brine project location

The Boardwalk property is located in west-central Alberta, Canada, directly to the south and west of Valleyview Town. It is positioned approximately 85km east of Grande Prairie City and 270km north-west of Edmonton City.

The property amalgamates 26 host-rock mineral permits and brine-hosted mineral licences into a contiguous land package totalling 170,424ha (421,126.8 acres).

Geology and mineralisation of Boardwalk project

The Boardwalk property occupies a central position within the west-central Alberta region and the Western Canada Sedimentary Basin (WCSB), just south of the Peace River Arch (PRA). Predominantly located on the Chinchaga Terrane, the property’s north-west corner extends onto the Ksituan Magmatic Arc.

Lithium mineralisation occurring within the Devonian Leduc Formation aquifer is dissolved in the brine, rendering it invisible in its physical form.

Broadwalk lithium brine project resources

The indicated and inferred resources at the Boardwalk lithium brine project are estimated to be 6.1 million tonnes (mt) of lithium carbonate equivalent (LCE) at a grade of 70.01 milligrams per litre (mg/l), as of August 2024.

Lithium mining method

The lithium production will involve the extraction of brine from the Leduc Formation via deep vertical or deviated wells, tapping into the brine water as an in-situ resource.

The objective is to produce 250,000m³/day of lithium-enriched brine over two decades from 50 wells. This brine will be channelled to a central processing facility (CPF) via electrical submersible pumps (ESP) to elevate the brine to the surface.

Once depleted of lithium, the brine will be reinjected into the formation through 50 injection wells to sustain pressure and avert premature breakthroughs. To minimise the surface footprint, the project will utilise up to 23 multi-well pads.

The wells will be drilled vertically from these pads and deviate in the subsurface to achieve the desired bottom hole target. Artificial lifts will be required for the wells, which will be achieved using ESPs.

Ore processing details

The lithium processing facility will be designed to yield roughly 34,252 tonnes per annum (tpa) of battery-grade lithium hydroxide monohydrate. This will be achieved by processing feed brine at a rate of 250,000m³ per day with an average lithium concentration of 70.1mg/l.

Raw brine will undergo hydrogen sulphide removal before the preconditioning and DLE stages. Subsequently, the brine will be filtered using pressurised filters filled with crushed walnut or pecan shells to remove oils and solids.

The DLE circuit will then selectively extract lithium, yielding a solution with elevated lithium levels and reduced impurities. The process involves lithium loading onto a sorbent, sorbent washing, lithium elution with sulfuric acid, and sorbent regeneration.

Following the extraction process, the lithium-depleted brine will be reinjected, while the lithium-rich eluate will undergo further purification.

The eluate will undergo treatment to remove impurities through neutralisation, preconditioning, and reverse osmosis. It will then be refined via ion exchange and converted into lithium hydroxide using an electrochemical process that involves lithium sulphate.

The resulting lithium hydroxide solution will undergo a two-stage crystallisation to produce purified lithium hydroxide monohydrate (LHM) crystals, which will then be washed, dried, and packaged for storage and delivery.

Site infrastructure

The property can be accessed through provincial highways and secondary single or dual-lane all-weather roads. Further access within the property is facilitated by a network of all-weather and seasonal gravel roads and tracks.

The Boardwalk processing plant will require approximately 167MW of power, with 35MW expected to be sourced from the Alberta Electrical System Operation (AESO) grid to wells in the eastern and southern areas. The remaining 132MW is proposed to be generated onsite to power the CPF and wells in the western and northwestern regions.

Water supply for the project will be sourced primarily from the Little Smoky River and also from groundwater via the Little Smoky Watershed.

Contractors involved

The contract for capturing emissions from the proposed power facility at the Boardwalk project has been awarded to advanced material science company, ZS2 Technologies, which will utilise its patented CO₂ Direct-Air-Capture (DAC) technology. Additionally, the company will process treated brine to extract magnesium and calcium for use in their magnesium cement products.

The PEA report for the project was prepared by engineering consultant, Hatch, with contributions from independent consultants, including APEX Geoscience, Fluid Domains, GLJ, Hydrogeological Consultants, Scott Energy, and Go2Lithium.