The Bayovar 12 Phosphate Project, covering an area of 12,575ha, is located approximately 65km south of Sechura and 90km south-west of Piura, northern Peru.

The project is owned by Focus Ventures through its 70% ownership rights in Juan Paolo Quay (JPQ), the owner of the Bayovar 12 concession. The remaining 30% interest in JPQ is owned by Trabajos Maritimos, and Inca Terminals and Mining, the subsidiaries of Grupo Romero (Peru) and Mamut Andino (Ecuador), respectively.

The prefeasibility study for the project was completed in January 2016 and was further updated in May 2016.

The overall investment to bring the Peruvian phosphate project into production is estimated to be $167m. The initial mine life is estimated at 20 years.

Bayovar 12 geology and mineralisation

The deposit is located within the shallow north-trending Sechura Basin, hosting successive inter-layered marine sediments including phosphorite, diatomite, sandstone, shale and volcanic tuff dating back to the Eocene and Pliocence ages.

The deposit’s phosphate-bearing units are found in the upper 135m to 215m of the Miocene strata within the Zapallal Formation, which dips gently to the east within the concession, with no faulting or folding. The phosphorite beds range in thickness from 0.31m to 1.76m.

Reserves at Focus Ventures’ flagship project

The Bayovar 12 Phosphate Project is estimated to hold combined proven and probable reserves of 58.77Mt grading 12.93% P2O5.

Measured resources are estimated at 17.7Mt grading 13.16% P2O5, indicated resources are estimated at 209.5Mt grading 13.04% P2O5, and inferred resources are estimated at 102.2Mt grading 13.11% P2O5.

Mining and processing at the Peruvian phosphate mine

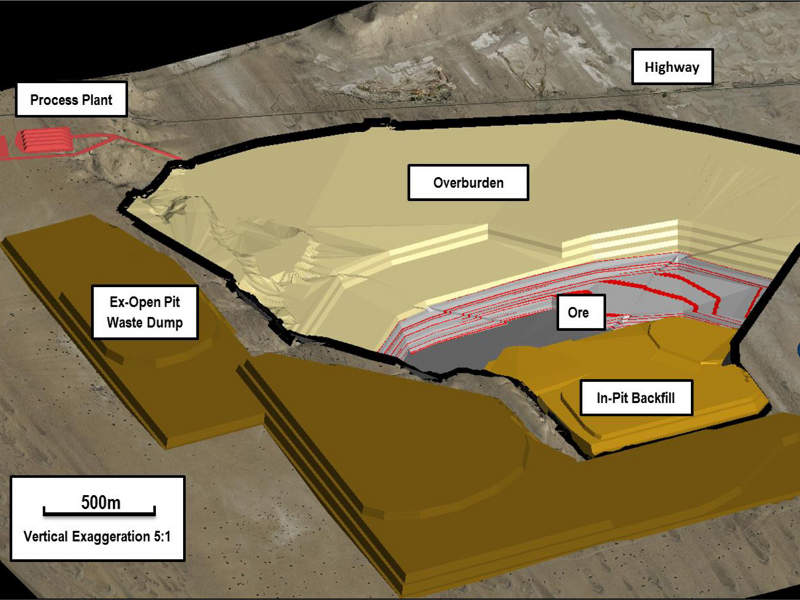

The mining method envisaged for the project is the open-pit mining method integrating free-digging and truck haul operations. The project aims at mining at a rate of 8,000t a day.

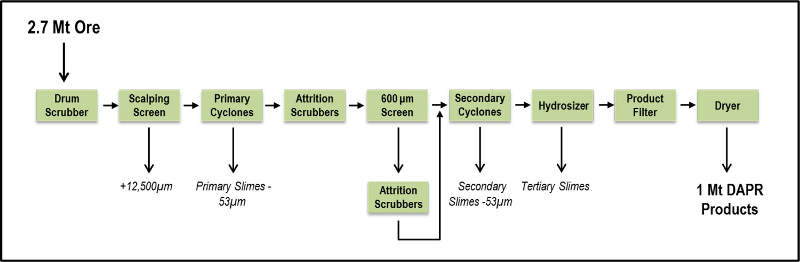

The processing facility proposed for the project is a beneficiation plant incorporating stages of desliming, dewatering to 15% moisture and drying to 4% moisture. The process flowsheet consists of drum washing, size classification, attrition scrubbing, hydraulic classification, filtering, and fluid bed drying.

Infrastructure for the phosphate project in Sechura Province

The project site is accessible through new unpaved roads connecting with the Bayovar-Chiclayo Highway, located 17km west of the Pan American Highway.

The electricity required for the project is proposed to be sourced from the La Niña substation. It will necessitate the installation of a 16km-long 138kV power transmission line and a new substation at the project site.

The seawater required for the processing facility will be piped to the project site via a new 45km-long and 32in-diameter HDPE pipeline. A new water storage pond and a reverse osmosis desalination plant are proposed to be constructed at the site.

Other major infrastructure for the project will include a 9.8 million square metre tailings storage facility (TSF), fire-protection facilities, communications facilities, a truck shop, a truck wash, a fuel storage facility, a process plant maintenance building, and other buildings housing a laboratory, administrative offices, change rooms, security offices, medicals rooms, and a cafeteria.

Concentrate transport details

The reactive phosphate rock (RPR) concentrates from the project are proposed to be transported by trucks to the Port of Bayovar, which is located 43km from the project site, via the Bayovar-Chiclayo Highway and the Pan American Highway.

The existing port facilities owned by JPQ will be upgraded to accommodate the additional capacity and keep the concentrates dry.

The phosphate concentrates from the project will primarily cater to the oil palm market in Colombia, Ecuador and South-East Asia, the agricultural markets in Brazil and Argentina, and the local Peruvian market.

Key players involved

The updated prefeasibility study report was compiled by M3 Engineering & Technology, with inputs from International Mining Consultants for the mine engineering, Golder Associates for the geological modelling and mineral resource estimation, geotechnical and hydrology studies and the tailings storage facility design, and Jacobs for the metallurgical testwork and process design.