The Barruecopardo tungsten project is situated in the Castilla y Leon region of Spain. It is developed by Saloro SLU.

Ormonde holds a 30% interest in the project while the remaining stake is held with Oaktree Capital Management.

A definitive feasibility study (DFS) for the tungsten mine was completed in February 2012. The open-pit mine is expected to produce 1.1 million tonnes per annum (Mtpa), according to the DFS report.

The project began operations in August 2018 with the first successful trial of waste rock through the primary crusher.

The rest of the crushing and screening plant, including associated electrical circuitry, was completed by September 2018. Commissioning of the screens and cone crushers commenced in November 2018 while construction activities were fully completed by June 2019.

Barruecopardo deposit’s geology and reserves

The Barruecopardo deposit strikes north-east and steeply dips towards the east. It is contained in a 1.6km-long granite-hosted, sheeted vein system. The system contains multiple mineralised zones.

77 holes totalling 15,241m have been drilled to estimate the resources of the mine. Mineral resource estimates of Barruecopardo stand at 27.39Mt grading at 0.26% of tungsten trioxide (WO3).

The mining property has an estimated proven and probable reserve of 8.69Mt grading at 0.30% Tungsten trioxide (WO₃).

Tungsten mineralisation at Barruecopardo

Tungsten mineralisation is found in quartz veins mostly in the form of coarse-grained scheelites less than 10cm in thickness. Intense veining at the deposit is nearly 40m-wide. Minor traces of wolframite are also part of the deposit.

Mining at Ormonde’s tungsten project

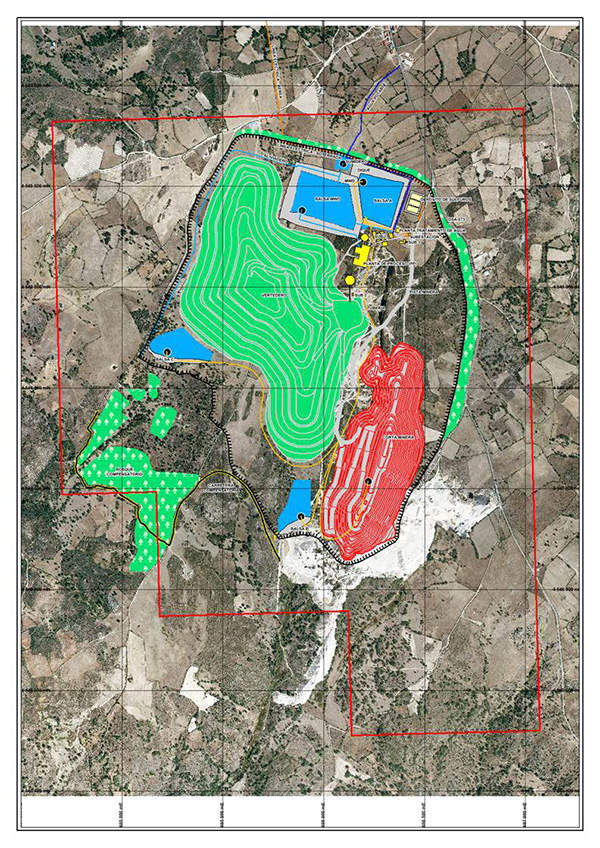

The Barruecopardo mine was operational until the 1980s when mining activities ceased due to unsafe and uneconomic conditions. These mining activities were carried out in the southern part of the mine in open pits that are 800m x 100m in size.

The steeply dipping structure of the mine facilitates ore extraction. The mining operations are being carried out using conventional open-pit methods of traditional drill and blast mining with shovel and truck operations.

Open-pit mining will continue for the first five years. After five years, underground mining using conventional mechanised bulk and open stoping mining methods will be carried out.

Open-pit mining of the surface ore zones commenced in January 2019. The open pits drilled for the current mining operations will be an extension of those drilled previously.

Ore processing at Barruecopardo tungsten project

The project does not require a primary grinding circuit because of its coarse mineralisation. Tailings dam is also not required, resulting in low capital and operational costs.

The design of the processing circuit is similar to that used during the mining operations in the 1980s. Test work carried out at the mine indicated that the processing plant can achieve tungsten recovery of nearly 78%.

The processing will begin with a four-stage 1.1Mtpa crushing circuit, which will crush the feed to a size of less than 5mm. The crushed ore will be screened before sending for gravity pre-concentration, in which heavy tungsten minerals will be recovered by jigs and spirals.

The next step includes a clean-up and tabling circuit, which will remove any sulphides present in the concentrate.

Transport and handling infrastructure at the tungsten mine

The project will benefit from the infrastructure available from previous mining operations. ‘Good’ infrastructure, in the form of roads and power lines, is located adjacent to the mine site. Infrastructure upgrades will be carried out to suit the requirements of the current mining operations.

The recovered ore will be transported through rail and road to mainland Europe, as well as ports to overseas countries.

Barruecopardo Tungsten Project Financing

Ormonde signed an agreement with Oaktree Capital Management in 2015 to fund the project with a combination of a $44.2m equity and a $55.5m debt.

Future developments near Barruecopardo

Related Project

Molyhil Tungsten and Molybdenum Project, Northern Territory, Australia

Molyhil tungsten and molybdenum mine is located 220km from Alice Springs in the Northern Territory of Australia. It is 100% owned and operated by Thor Mining.

Within the Barruecopardo mining licence, several other prospects are contained, which are expected to increase the resource volume of the project. The most significant prospect among these is the Valdegallegos prospect located 1km west of the Barruecopardo mine.

Two holes were drilled at the Valdegallegos prospect as part of a drilling programme focused on identifying adjacent prospects. One of these holes intersected high-grade mineralisation of 0.9m grading at 2.6% WO3.

Another prospect at the mine is the Saturno, which contains 3m to 8m thick tungsten and a gold-bearing mineralisation zone.

Contractors involved

Jacobs Engineering built the gravity processing plant at the project.

Metso installed and commissioned the flotation circuit for the project, along with the necessary training.