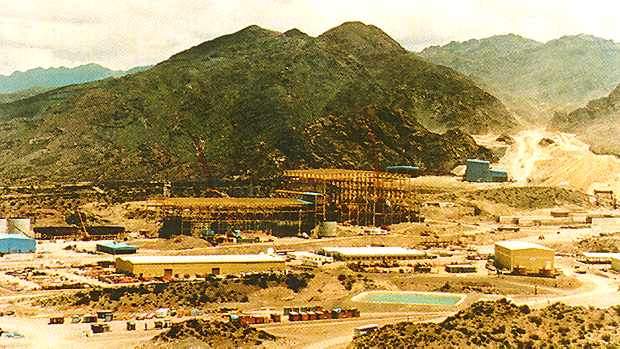

The Bajo de la Alumbrera (Alumbrera) copper-gold mine in Argentina is owned and operated by Minera Alumbrera (MAA). It commenced commercial operation in February 1998. The mine is located in Catamarca province, 1,100km north west of Buenos Aires at an altitude of 2,500m.

The Argentine state- and provincially-owned mining company, Yacimientos Mineros de Agua de Dionisio (YMAD), which has the title to the deposit, awarded an international tender for the Alumbrera concession to International Musto Exploration in 1992. Minera Alumbrera was formed in 1994 when MIM Holdings bought a 50% operating interest. During 1995, North Ltd and Rio Algom acquired shares in International Musto and each took a 25% holding in MAA. Pre-production capital expenditure totalled $1.2bn and capital expenditures in the 1998 and 1999 financial years were $198m and $17m respectively. Royalty payments to Catamarca province commenced in 1998. YMAD will start earning 20% of the net proceeds (before tax) once project capital plus interest has been repaid.

In 2003, three years after Rio Tinto acquired North Ltd and Billiton (now BHP Billiton) bought Rio Algom, the two companies sold their holdings to the Canadian company, Wheaton River Minerals, while MIM was acquired by Xstrata. In 2005 Xstrata opened an office in Chile, initially to manage both Alumbrera and the company’s Las Bambas copper project in Peru.

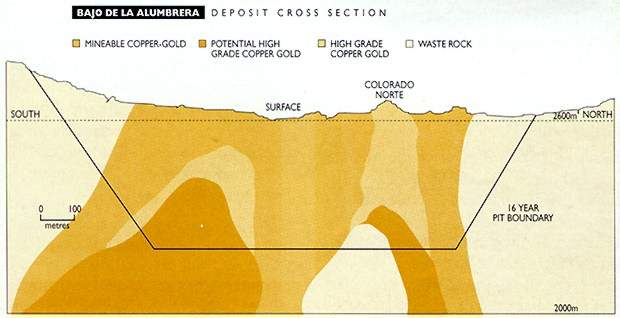

Geology and reserves

The Bajo de la Alumbrera deposit is a classic copper-gold porphyry. Porphyritic dacite intrudes volcanic andesite, chalcopyrite being the main copper mineral. Near-surface weathered material overlies primary sulphide. By June 2009 the mine’s reserve base totalled 338Mt proven grading 0.4% copper, 0.39g/t gold and 0.013% Molybdenum. plus 10Mt probable ore reserves grading 0.33% copper, 0.3g/t gold and 0.015% Molybdenum.

Minign and processing

The mining area measures 1.8km by 1.8km. Pre-stripping involved the removal of only 25Mt and the initial strip ratio was 1.4:1.

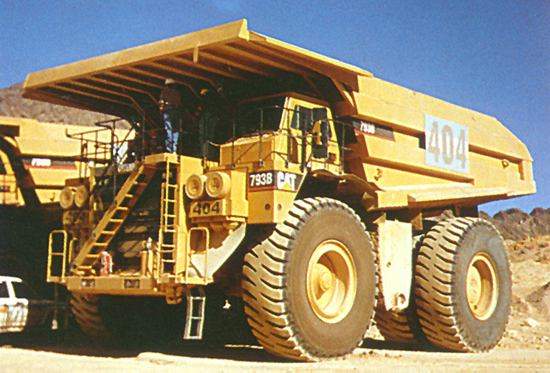

Mining is conventional: drilling with five large machines and blasting and loading by three Bucyrus 495-B shovels with 43m³ buckets; haulage by 50 Caterpillar 218t-capacity trucks; and support from two LeTourneau L-1800 electric drive wheeled loaders. Four new haul trucks arrived in 2004.

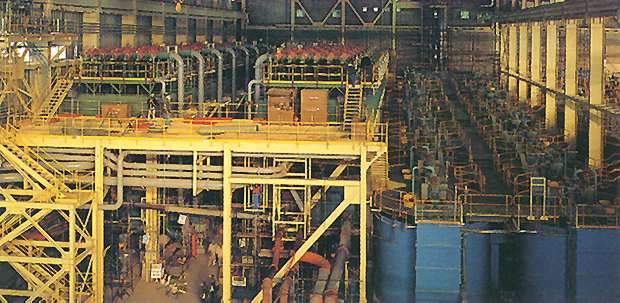

The concentrator was initially designed to treat 80,000 to 85,000t/d, yielding 700,000t/y of copper concentrate. Design recovery rates were 91% for copper and 70% for gold.

Run-of-mine ore is handled in an 8,400t/h Svedala gyratory crusher, which feeds a coarse ore stockpile. Two SAG and two ball mills – also supplied by Svedala – supply ore via sizing hydrocyclones to either the free gold, gravity separation doré metal system, or to the flotation section. The latter comprises 100m³ of rougher cells, a regrinding mill, and Jameson cell cleaner and scavenger flotation.

During 2001–02, the concentrator capacity was expanded by 30% to maintain metal-in-concentrate output at 190,000t/y of copper and 600,000oz/y of gold. A pebble crushing circuit and additional grinding capacity were installed.

In 2004, MAA commissioned a third flotation circuit, and in 2005, Xstrata Copper announced a $15.5m expansion to raise the plant’s capacity from 37Mt/y to 40Mt/y in orde to make full use of the Tucuman filtration plant at Cruz del Norte. Concentrates are pipelined 316km after thickening to 63% solids to the Cruz del Norte plant. After de-watering by Larox pressure filters, it is railed to Puerta Alumbrera, constructed by Krupp Fördertechnik, on the Parana River. The expansion was commissioned in November 2006, 35 days ahead of the original schedule.

A project to set up a new molybdenum flotation plant was approved in July 2006. Construction was completed in the last quarter of 2007 at a cost of $16m. Set up besides the existing Alumbrera concentrator, the plant produced its first molybdenum concentrate in the first quarter of 2008.

Commissioning of the new molybdenum plant took place in 2008. By the end of 2008, the plant produced 450t of molybdenum. In July 2009, a new flotation circuit was commissioned.

Production

Mining consistently reached target rates in the second quarter of 1999. During calendar 2008 Alumbrera produced 28Mt of ore, grading an average of 0.50% copper and 0.55g/t gold.. The operation treated 37Mt of ore to produce 156,893t of copper-in-concentrates, plus a total of 60,484oz of gold in doré and 443,919oz in concentrate.

More than 50% of the concentrate is sold on long-term contracts, while doré is refined in the USA.