The Ayawilca polymetallic project is a zinc-silver project located in central Peru. Owned by Tinka Resources, the project comprises three separate mineral deposits: Ayawilca zinc zone (sulphide), Colqui silver zone (oxide), and Tin Zone (sulphide).

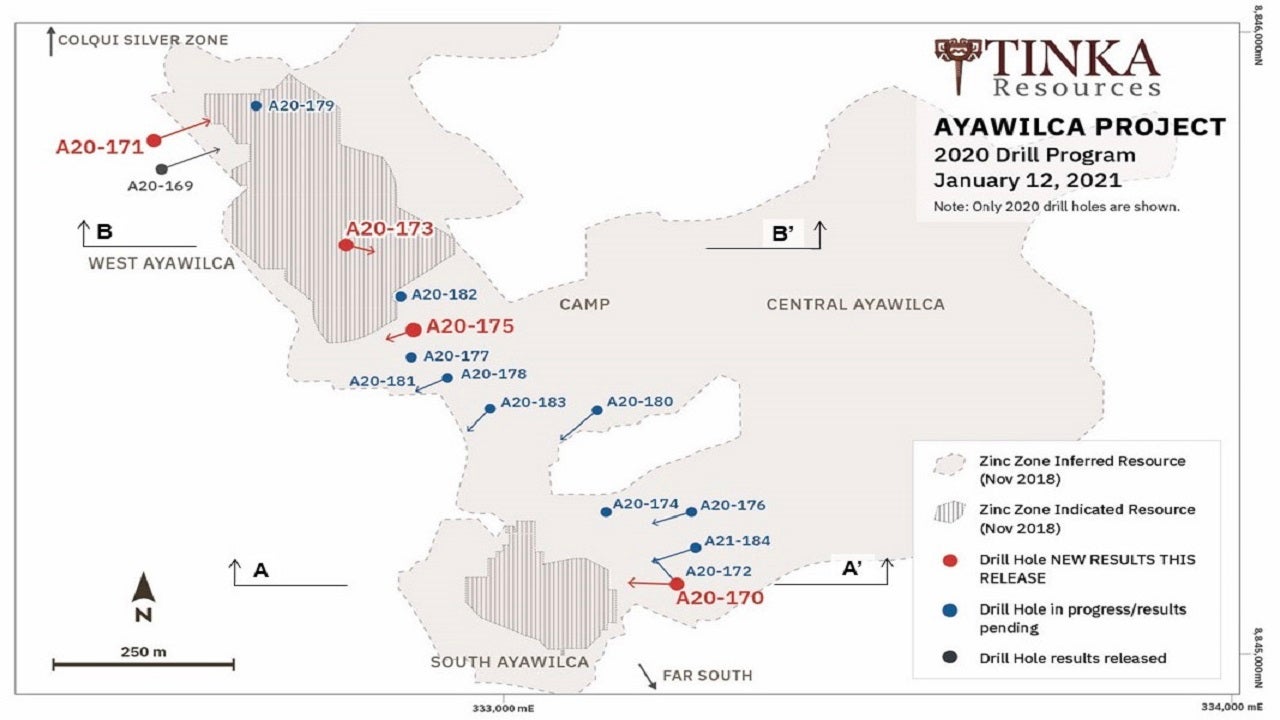

The largest resource on the property, the Ayawilca zinc zone was discovered in 2013. Tinka drilled 6,000m out of the total planned 7,500m drilling programme as of January 2021 to expand project resources. The property is one of the largest zinc-silver resources owned by a junior company.

Ayawilca polymetallic project location

The Ayawilca property is located 200km northeast of Lima, within the Pasco region of Peru. The location is within the Yanahuanca and San Pedro de Pillao districts in the Daniel Alcides Carrion province.

The zinc-silver project is situated 40km away from the Cerro de Pasco copper-zinc-lead-silver mine and 100km from the Antamina copper-zinc mine.

The site is accessible from Lima by road through the Panamerican Highway, and an alternative route of the Central Highway to Cerro de Pasco and a further paved road to Yanahuanca.

Geology of Ayawilca polymetallic project

Ayawilca is a carbonate replacement deposit (CRD), which is a major type of silver-zinc-lead (-copper) mineralisation.

The project is located in the High Andes zone, which includes a deep basin, a continental shelf, an intra-arc trough, and the Marañón metamorphic complex.

The project geology is represented by sedimentary and metasedimentary stratigraphy ranging from the age of late proterozoic to tertiary, with the oldest documented rock belonging to the Excelsior group of the Devonian age. It is overlain by red-bed terrestrial sediments comprising conglomerate, sandstone, and intercalated mudstone from the permian to lower triassic mitu group.

The zinc and tin zones are primarily present within the pucará group’s sequence of limestone, dolomite, limestone breccia, arenite and greywacke, and calcareous siltstone.

Ayawilca polymetallic project resources

The Ayawilca polymetallic project is estimated to contain 11.7 million tonnes (Mt) of indicated resources graded at 6.9% of zinc (Zn), containing 28,448 million ounces (Moz) of zinc as of November 2018.

The total inferred resources are estimated to be 45Mt of zinc graded at 5.6%, with contained zinc of 89,360Moz.

Mining at Ayawilca polymetallic project

The project will employ underground mining methods, following the rejection of the open-pit mining method based on a 2019 review that found the open pit method to be economically unviable.

A pre-production period of one year will see the development of initial underground infrastructure. Production is planned to begin in the upper levels, targeting higher-grade material and zones.

The main levels of the mine will be spaced at vertical intervals of 70m, with a sub-level spacing of 35m. A ramp system will provide access to the mine by connecting the mine portals to the underground infrastructure. The north 4255 and west 4035 access portals will act as the main and secondary accesses while nine ventilation raises will also be created.

The mined-out stopes will be backfilled with a fill comprising paste and cemented rockfill types.

The underground mining fleet will include equipment for mucking, haulage and drilling, along with raise bore and boxhole equipment for underground and surface support, and light vehicles.

Processing at Ayawilca polymetallic project

The project will utilise a conventional coarse lead and standard zinc flotation-based processing circuit. The run-of-mine (ROM) ore will be hauled to the crushing area via dump trucks and discharged into a ROM hopper.

The 5,000 tonnes a day (t/d) processing plant will include primary jaw crushing, semi-autogenous grind (SAG) milling, and secondary ball mill grinding. The plant will have a concentrate dewatering unit for zinc and lead-silver concentrates, a tailings storage facility (TSF) for flotation tailings thickening and disposal, and a tailings backfill plant. A part of the tailings will be used as mine backfill material while the rest of it will be disposed in a conventional TSF.

A coarse flotation stage with two unit / flash cells at the secondary grinding discharge will be included for the recovery of the lead content. Zinc recovery will be undertaken in a rougher and two-stage cleaner-scavenger flotation circuit.

Infrastructure at Ayawilca polymetallic project

The primary infrastructure at the project site includes the accommodation facilities, site and internal access roads, TSF, and other project ancillary infrastructure. In addition to a 500-person accommodation camp, the general mine and process facilities will include a mine truck shop, plant maintenance workshop, laboratory, water ponds, general warehouse, an administrative office building, explosives storage magazine, and a core shed.

The reclaimed water from the TSF is expected to be the main source of water for the process plant.