The Kalahari Manganese field is located in the Northern Cape Province, 700km south-west of Johannesburg, South Africa. It contains approximately 80% of the world’s known high-grade manganese ore reserves. The district yields four million tonnes per annum (Mtpa), which is mined mainly by two companies: Samancor and Assmang.

Originally established in 1935, Assmang is jointly owned and managed by African Rainbow Minerals and Assore. The company wholly owns the Nchwaning and Gloria manganese mines, near the Black Rock area of the Kalahari Manganese field.

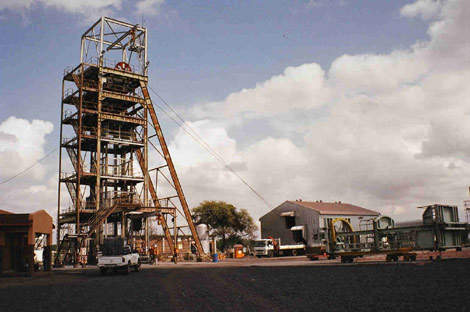

Nchwaning was commissioned in three phases. Nchwaning 1 was commissioned in 1972, Nchwaning 2 in 1981 and Nchwaning 3 in 2001. The Gloria mine, to the south, started production in 1978.

Both the mines had processing plants nominally rated to treat 1Mtpa of ore. This capacity has gradually been increased over the years through a series of upgrades.

Expansion at Nchwaning manganese mine

In early 2000, Assmang announced an expansion involving the development of a new shaft complex at Nchwaning to add 2Mtpa of run-of-mine ore capacity. The expansion made Nchwaning the world’s lowest-cost underground manganese mine and extended its lifetime by 30 years.

The expansion, including additional treatment capacity, was commissioned in May 2004 and was completed in May 2005 at a capitalised cost of R780m ($120.75m).

In June 2010, Assmang completed the construction of an R500m ($65.3m) processing plant and doubled the output from 3Mtpa to 6Mtpa. The new plant can process 900tph of ore from Nchwaning 2 and 3.

In 2014, an expansion project was undertaken at both the Gloria and Nchwaning underground mines to increase the mining capacity from 3.2Mtpa to 4.6Mtpa. The expansion project involved refurbishments, upgrades and new installations, in addition to the sinking of a 167m-deep ventilation shaft with a 5.5m diameter at the Gloria underground mine.

Assmang secured approval from environmental authorities for an expansion of the Gloria manganese mine in September 2018. The project will upgrade the rock handling infrastructure and surface processing plant at the mine, as well as related infrastructure to reduce water and energy consumption. The project is expected to be completed in late 2021.

Geology and reserves at the Kalahari Manganese field

The Kalahari Manganese field lies within a large structural basin that extends approximately 40km south to north and 5km to 15km east to west, dipping gently north-west.

At Black Rock, near the northern end of the basin, the Transvaal System rocks lie 300m from the surface, beneath Kalahari Formation sands and calcretes, Karroo System tillites and Waterberg System shales and quartzites.

The sub-horizontal stratabound manganese ore horizons occur in banded ironstone of the Voëlwater Formation at the top of a sequence of Transvaal System rocks. As well as being faulted, the horizons are folded.

The ore is massive and averages 48% manganese; at Nchwaning it is particularly low in phosphorus, while Gloria has a higher manganese-to-iron ratio.

Nchwaning has two manganese seams. Seam one is six-metre thick and situated approximately 400m underground while seam two is located above seam one at Nchwang 2. Seam two can be accessed through the Nchwaning 2 shaft. Gloria manganese seam one is estimated to contain 35.44Mt of mineral reserves. Mineral reserves of 3.85Mt were identified at Nchwaning Seam two in 2013, where mining started in 2014.

As of 2019, Nchwaning’s total measured and indicated resources were 303.95Mt, while proven and probable reserves were 177.86Mt. Gloria’s measured and indicated resources were 65.99Mt, while proven and probable reserves were 115.04Mt.

Mining at Nchwaning and Gloria mines

Both mines are underground operations, using the room-and-pillar method. Nchwaning started with one vertical hoisting shaft, with the 450m-deep No 2 vertical skip shaft added and the plant upgraded in 1981.

Gloria combined a vertical shaft for personnel and materials hoisting with a long incline shaft for vehicle access and conveyor hoisting of the ore to a surface crushing, screening and washing plant.

The 2004 expansion follows this design, having a 2,200m-long incline shaft and the 500m-deep Nchwaning No.3 personnel shaft. There is also a ventilation shaft and a workshop located on the 400m level.

Bolted development entries access rooms that are 7m to 8m wide and 3.2m to 3.5m high while the pillars are normally 8m x 8m. Low-grade ore is left to form both the floor and roof of the rooms.

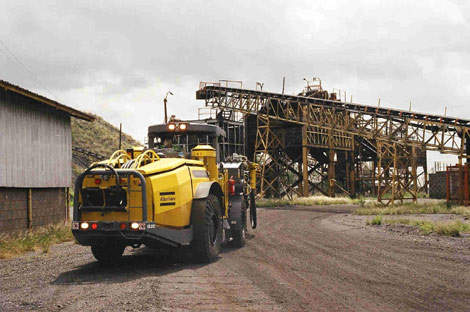

The established areas use Boart Longyear hydraulic drilling rigs and Wagner load-haul-dump (LHD) machines and trucks to transport the ore to storage silos, primary crushers and screens that feed the hoisting systems. Roofs are scaled using a modified three-wheeled loader.

For the new area, Assmang requested a three-boom rig fitted with two rock drills for face work plus one for roof-bolting, so the mine can drill holes for roof bolts and face-blast holes from the same set-up.

Assmang also added to its fleet of Atlas Copco Wagner LHDs but opted for an alternative truck brand, ordering three Caterpillar AD 30 machines.

Processing and production

Shaft complex Nchwaning 3 provides access to high-quality ore. Production from this complex commenced in May 2004 and became fully operational in February 2006. This new mining operation is serviced by two shafts; a vertical personnel shaft to a depth of 350m and a decline shaft equipped with conveyors, which is the main hoisting shaft. Hoisting capacity varies 200,000t a month.

The existing plant was upgraded and treats the ore from both Nchwaning 2 and 3 mines. The run-of-mine ore is crushed, washed and screened, with no other processing needed. After the ore has passed through the plants, it is stacked according to size and grade. The capacities of the stacks vary between 280t and 320t each, and are numbered and sampled.

Exports travel by the main South African Railways route to Port Elizabeth on the Indian Ocean. Lesser tonnages are directed to the domestic steel industry. The feasibility study for exporting manganese through the Saldanha Port was completed in 2012.

Contractors involved

WorleyParsons was responsible for the expansion of the mining capacity to 4.6Mt per annum in 2014. Murray & Roberts Cementation was also involved in the project.

DRA Global secured the engineering, procurement, construction management (EPCM) contract for the expansion project at the Gloria mine.

Atlas Copco supplied four purpose-designed Rocket Boomer M3D rigs for the mine.