Asanko Gold Mine, situated in Ghana, one of the top ten gold producing countries, is Asanko Gold’s flagship project. With proven and probable reserves of 4.8 million ounces (Moz), the mine is being developed in two phases.

Construction on the phase one development of the project started in August 2014. The first gold was poured from the phase one in January 2016, while commercial production began in April 2016.

A definitive feasibility study for the phase two of the project was modified in 2016 to include a two-stage approach for the extraction of the nearby Esaase deposit. Phase two has potential to expand the mine’s gold output to 400,000oz a year.

Geology and reserves

Phase one of Asanko gold mine development comprises Nkran, Abore, Adubiaso, Dynamite Hill and Asuadai deposits.

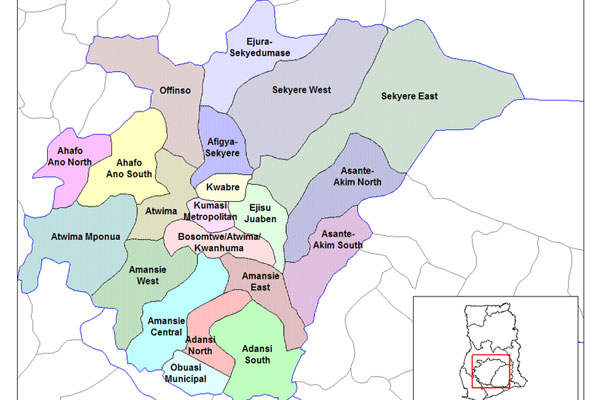

These are situated in the Asankrangwa Belt within the Kumasi Basin that hosts world-renowned gold mines, including AngloGold Ashanti’s Obuasi deposit. The Esaase deposit, planned to be developed as part of phase two, is also located in the Asankrangwa Belt around 25km north of the processing plant site near the Nkran pit.

The mineralisation in all these deposits is characterised by a system of gold-bearing quartz veins hosted by the tightly folded meta-sediments.

The mine is estimated to hold combined proven and probable reserves of 97 million tonnes (Mt) grading at 1.68g/t, for 5.25Moz of gold.

Gold mine development

Phase one is based on the September 2012 Definitive Feasibility Study (DFS) for the Obotan Project. Previously owned by PMI Gold Corporation, the project was acquired by Asanko Gold in February 2014.

The preliminary mining plan for the project called for the economic production of approximately 2.25Moz of gold during 11.5 years of planned mine life using open-pit mining method.

Asanko Gold, however, increased the capital cost estimate of the project to $295m, considering the infrastructure development required to support the possible inclusion of the phase two development.

The company announced the start of early construction works involving detailed engineering and start of bulk earthworks at the project site in April 2014. A $16m budget was approved for this purpose. The company confirmed mineral resources for phase 1 in September 2014, which was estimated to be 49.63Mt of ore grading 2.22g/t Au in measured and indicated categories.

The Definitive Project Plan for phase one was published by the end of 2014.

A temporary mining permit allowing mining operations to start at the Esaase deposit was received in June 2014.

Mining and processing

Asanko Gold Mine employs conventional open-pit mining method for extracting ore during the initial years. The extracted ore is processed at the carbon-in-leach (CIL) processing plant located near the mine site, which has the capacity to process three million tonnes a year.

Infrastructure and construction

An existing 11km road running between the Nkran pit, the proposed location of the processing plant site and the Abore pit was upgraded to be used as the access road to reach the site. The airstrip at the site has also been upgraded.

A 161kV electrical infrastructure was built with an $18.18m investment to provide power to the mine. The construction of the processing plant was completed at a cost of approximately $85m, while the buildings, offices and other accommodation facilities were built at an estimated cost of $12.31m.

Other facilities, including the tailing storage facility (TSF), waste rock dump (WRD) facility, run-of-mine (ROM) facility and the water supply facility, along with associated civil works, cost up to $23.08m.

Construction of phase one created approximately 1,000 jobs, while around 700 people are employed during the operation phase.

Financing the Asanko project

Asanko Gold signed a $150m debt facility agreement for the phase one development in July 2014 with a special-purpose vehicle of RK Mine Finance Trust I (Red Kite) that includes $130m of project facility, and $20m of cost overrun facility.

Contractors involved

DRA was awarded the engineering, procurement and construction management (EPCM) contract for the project in April 2014. Knight Piesold was simultaneously appointed as the design contractor for the TSF.